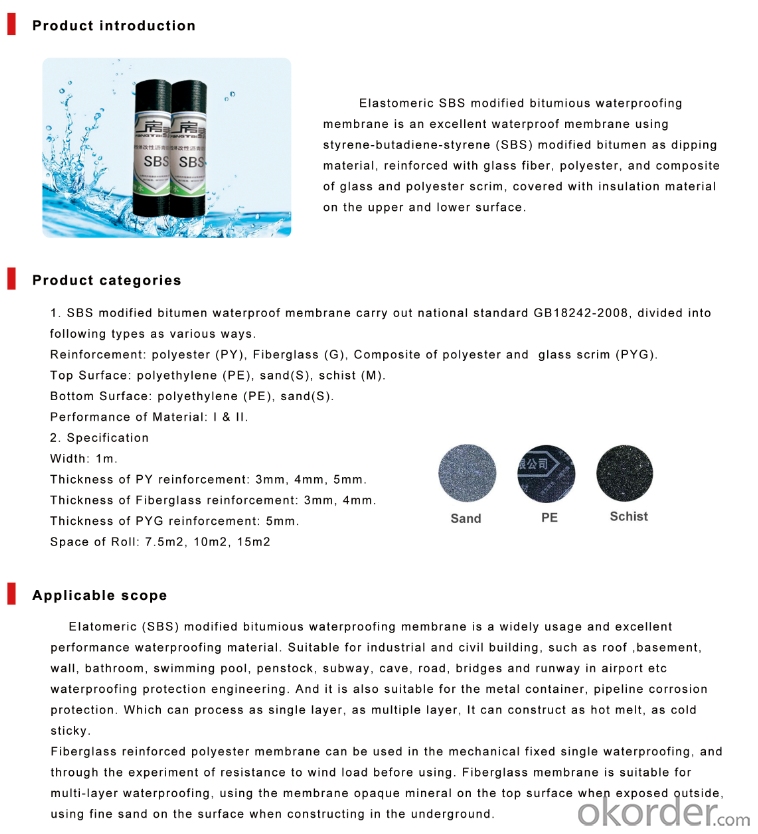

Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Self-adhesive polymer modified bitumious waterproofing membrane using polymer modified bitumen adhesive material as main material(internal could have reinforcement),double or single coated with silicone oil isolating membrane or isolating paper as antiseize

II. Product Categories:

Reinforcement: no reinforcement (N) polyester (PY)

Top surface of N type: polyethylene (PE), polyester (PET), double sides adhesive without film (D).

Top surface of PY type: polyethylene (PE), sand(S), double sides adhesive without film (D).

Performance of Material: I & II. Thickness of 2.0mm of PY only have I type.

III. Product features:

The construction of the membrane is concise and environmental: without firing, remove the isolation can adhesive at the basic tightly, it's environmental and economic.

2. Good elongation and elasticity, so it could adapt to deformation and cracking of basic well.

3. The membranes adhesive performance with basic is excellent, can avoid running water.

4. The self-healing is strong. the adhesive layer can heal automatically to protect waterproof layer in the case of puncturing.

IV. Applicable scope:The waterproof membrane is suitable for industrial and civil roofing, basement, indoor, municipal engineering, reservoirs, swimming pool, subway, road and tunnel. It also used in wood and metal roofing especially suitable for oil depot, chemical factory, textile mill, granary etc.

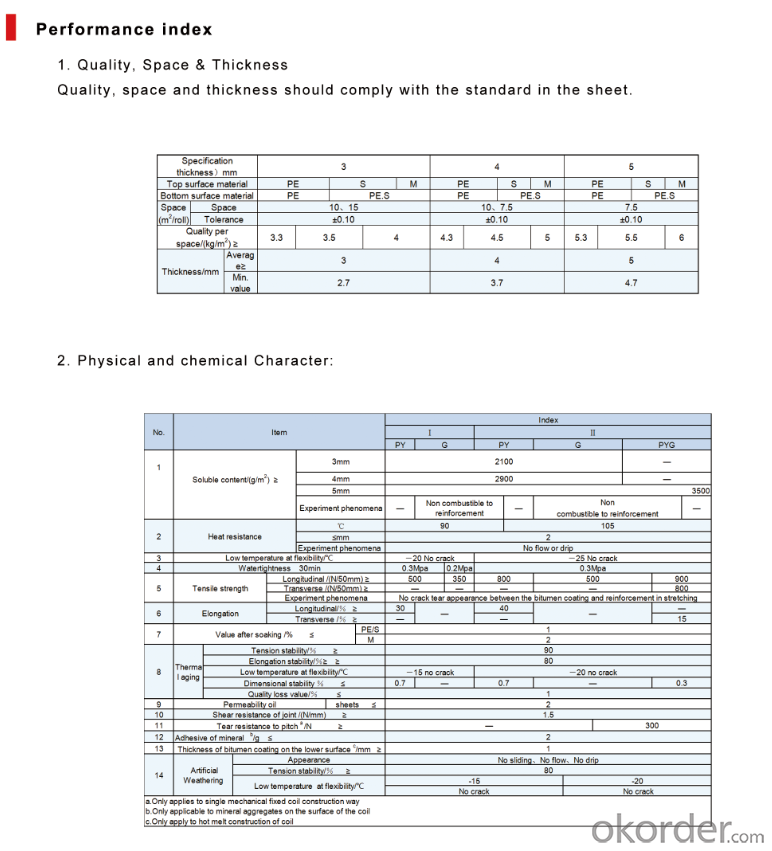

V. Performance index:

Physical and chemical Character of N type

No. | Item | Index | ||||||

PE | PET | D | ||||||

I | II | I | II | |||||

1 | Tensile strength | Tension(N/50mm) ≥ | 150 | 200 | 150 | 200 | -- | |

Longitudinal/% ≥ | 200 | 30 | -- | |||||

Bitumen elongation/% ≥ | 250 | 150 | 450 | |||||

Stretch phenomenon | Before membrane cracking no crack tear appearance between the bitumen coating and membrane in stretching | |||||||

2 | Tear resistance to pitch/N ≥ | 60 | 110 | 30 | 40 | -- | ||

3 | Heat resistance℃ | 70℃ sliding no more than 2mm | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | -20 | -30 | -20 | ||

No crack | ||||||||

5 | Watertightness | 0.2Mpa ,120Min | -- | |||||

6 | Peel strength N/mm ≥ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil | 2 | ||||||

9 | Holding power | 20 | ||||||

10 | Thermal aging | Tension stability/% ≥ | 80 | |||||

maximum tension elongation/% ≥ | 200 | 30 | 400 | |||||

Low temperature at flexibility/℃ | -18 | -28 | -18 | -28 | -18 | |||

No crack | ||||||||

Peel strength coil and aluminum plate N/mm ≥ | 1.5 | |||||||

11 | Heat stability | Appearance | No drum,fold,sliding,flow | |||||

Dimensional stability/%≤ | 2 | |||||||

Physical and chemical Character of PY type products

No. | Item | Index | ||||||

I | II | |||||||

1 | Soluble content/(g/㎡) | 2.0mm | 1300 | -- | ||||

3.0mm | 2100 | |||||||

4.0mm | 2900 | |||||||

2 | Tensile strength |

| 2.0mm | 350 | -- | |||

3.0mm | 450 | 600 | ||||||

4.0mm | 450 | 800 | ||||||

Maximun tension elongation/% ≥ | 30 | 40 | ||||||

3 | Heat resistance | 70℃ no sliding、no flow、no drip | ||||||

4 | Low temperature at flexibility/℃ | -20 | -30 | |||||

No crack | ||||||||

5 | Watertightness 30min | 0.3MPa,120min | ||||||

6 | Peel strength/ | Coil and coil | 1.0 | |||||

Coil and aluminum plate | 1.5 | |||||||

7 | Screw rod water tightness | pass | ||||||

8 | Permeability oil/ amount of sheets ≤ | 2 | ||||||

9 | Holding power/min ≥ | 15 | ||||||

|

| maximum tension elongation/% | 30 | 40 | ||||

Low temperature at flexibility | -18 | -28 | ||||||

Peel strength Coil and aluminum plate/(N/mm)≥ | 1.5 | |||||||

Dimensional stability/% ≤ | 1.5 | 1.0 | ||||||

11 | Self-adhesive bitumen peel strength/(N/mm) ≥ | 1.5 | ||||||

Product Description

Construction Process

Test Machines

Certificates

Company Information

- Q:Can a waterproofing membrane be used in swimming pools or other water features?

- Yes, a waterproofing membrane can definitely be used in swimming pools or other water features. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water leakage and damage. A waterproofing membrane acts as a barrier between the water and the surrounding structures, ensuring that the water is contained within the pool or water feature. It helps to prevent water seepage, which can cause structural damage and lead to costly repairs. Additionally, a waterproofing membrane also helps to protect the pool or water feature from the harsh chemicals used for water treatment, ensuring its longevity and durability. Therefore, using a waterproofing membrane is a crucial step in the construction or renovation of swimming pools or other water features to ensure their functionality and longevity.

- Q:Can waterproofing membranes be used on concrete planters?

- Yes, waterproofing membranes can be used on concrete planters. Waterproofing membranes are designed to create a barrier against water, preventing it from seeping through the concrete and causing damage. By applying a waterproofing membrane to the concrete planter, you can ensure that the planter remains watertight, preventing water from leaking out and potentially damaging the surrounding area. This can be especially beneficial for planters located indoors or in areas where water leakage could cause structural damage or create a mess. Additionally, waterproofing membranes can also help protect the concrete from freeze-thaw cycles, which can cause cracking and deterioration over time. Overall, by using waterproofing membranes on concrete planters, you can extend their lifespan and maintain their functionality for a longer period of time.

- Q:Can a waterproofing membrane be used for tunnels or underground structures?

- Yes, a waterproofing membrane can be used for tunnels or underground structures. Waterproofing membranes are designed to prevent water infiltration and can be applied to the interior or exterior surfaces of tunnels or underground structures to protect them from water damage. These membranes create a barrier that prevents water from seeping into the structure, ensuring its longevity and structural integrity.

- Q:Can a waterproofing membrane be used for food processing facilities?

- Yes, a waterproofing membrane can be used for food processing facilities. Waterproofing membranes are commonly used in various industries, including food processing, to ensure protection against water penetration and moisture damage. In food processing facilities, where hygiene and cleanliness are of utmost importance, waterproofing membranes can be applied to floors, walls, and ceilings to prevent water or other liquids from seeping into the building structure. Waterproofing membranes create a protective barrier that effectively seals the surfaces, preventing the growth of mold, mildew, and bacteria that can contaminate food products. They also help in maintaining a clean and dry environment, reducing the risk of slips, falls, and accidents caused by wet surfaces. Food processing facilities often deal with water-intensive processes such as cleaning, washing, and sanitizing, making it crucial to have a reliable waterproofing system in place. Additionally, waterproofing membranes can offer resistance to chemicals, oils, and other substances commonly used in food processing, ensuring long-term durability and protection. It is important to note that when selecting a waterproofing membrane for a food processing facility, it is necessary to choose a product that complies with industry standards and regulations. The membrane should be food-grade and certified safe for contact with food products to avoid any potential contamination risks. Overall, using a waterproofing membrane in food processing facilities can help maintain hygienic conditions, protect the building structure, and ensure compliance with health and safety regulations.

- Q:How does a waterproofing membrane handle movement in structural elements?

- A waterproofing membrane is designed to handle movement in structural elements by being flexible and accommodating any shifts or expansions that may occur. It can stretch and contract with the movement of the building, ensuring that it remains intact and continues to provide a watertight barrier.

- Q:How does a waterproofing membrane handle movement or settling of the structure?

- A waterproofing membrane is designed to be flexible and accommodate the movement or settling of a structure. It can stretch or contract as the building expands or contracts, ensuring that it remains intact and maintains its waterproofing properties. This flexibility helps to prevent any cracks or gaps from forming in the membrane, which could otherwise lead to water leakage.

- Q:Can a waterproofing membrane be used on precast brick surfaces?

- Precast brick surfaces are vulnerable to water penetration, which can lead to structural damage and the growth of mold or mildew. To prevent this, a waterproofing membrane can be utilized. The membrane, typically composed of rubberized asphalt, modified bitumen, or polyurethane, is a flexible and durable material. It is applied to the surface using a brush or roller, forming a seamless layer that effectively blocks water infiltration into the bricks. Moreover, apart from its water-resistant properties, the waterproofing membrane also enhances the thermal insulation and longevity of the precast brick surfaces. However, it is crucial to ensure that the precast bricks are thoroughly cleaned, dried, and properly prepared prior to the application of the membrane for optimal adhesion and efficacy.

- Q:What is the cost of a waterproofing membrane installation?

- The cost of a waterproofing membrane installation can vary depending on various factors such as the size and complexity of the area to be waterproofed, the type of membrane being used, and the location of the project. Generally, the cost can range from $3 to $10 per square foot. For a basic installation, which typically involves applying a liquid or roll-on membrane, the cost can be on the lower end of the spectrum. However, if the project requires additional preparation work such as repairing cracks or uneven surfaces, the cost may increase. Moreover, the type of membrane being used can also impact the cost. There are different types of waterproofing membranes available, including bituminous membranes, thermoplastic membranes, and elastomeric membranes. Each type has its own advantages and disadvantages, and the cost can vary accordingly. Additionally, the location of the project can influence the cost. Labor and material prices may vary depending on the region or city, and contractors may also consider transportation costs if the project is in a remote area. It is important to obtain multiple quotes from reputable contractors to determine the specific cost for your waterproofing membrane installation. Consulting with professionals and discussing your specific requirements will help you get an accurate estimate for your project.

- Q:How does a waterproofing membrane prevent water penetration?

- A waterproofing membrane prevents water penetration by creating a physical barrier that is impermeable to water. This membrane is usually made of a durable material such as rubber, PVC, or bitumen, which is applied to the surface to be waterproofed. The membrane effectively seals the surface, preventing water from seeping through cracks, joints, or pores. Additionally, the membrane may have additives that enhance its waterproofing properties and ensure long-term protection against water ingress.

- Q:Can a waterproofing membrane be used for a basement wall?

- Yes, a waterproofing membrane can definitely be used for a basement wall. In fact, it is highly recommended to use a waterproofing membrane on basement walls to prevent water infiltration and potential damage. Basement walls are particularly vulnerable to moisture due to their below-ground location, and a waterproofing membrane provides an effective barrier against water penetration. This membrane is typically applied to the exterior side of the basement wall, creating a protective layer that keeps the basement dry and prevents water from seeping into the foundation. It is essential to ensure proper installation and maintenance of the waterproofing membrane to effectively safeguard the basement from water-related issues such as leaks, mold, and structural damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Elastomeric sbs Modified Bitumious waterproofing rolls for basement or roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords