Economic Single Side Bracket for Retaining Wal

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete wall formwork

retaining wall formwork

permanent formwork systems

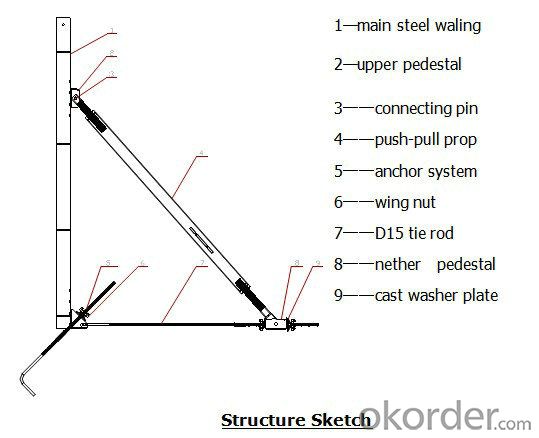

H20 Timber Beam Formwork with Simple / Economic Single Side Bracket for Retaining Wal

SB system – B is a kind of neat single side bracket, compared with single-side bracket, it is small in sizes and easy to assemble & dismantlement, it is widely used for retaining wall construction.

Competitive Advantage:

1. The pouring height is up to 3.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Simple structure, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

Applications:

- Q:Construction side without approval without authorization after removal of pouring with the template, what kind of remedial measures should be taken Thank you!

- When the concrete scaffolding is actually used to support the upper structure, to the concrete conservation period is allowed to remove the general is more than the demolition, and then used in the above level, indoor support with the steel scaffolding does not meet the requirements of the scaffolding decoration, interior decoration With the full scaffolding in the decoration when re-erected. Outdoor scaffolding in the pouring concrete can be erected when the masonry and decoration.

- Q:Frame support system in the framework of the support system of wood support has been unable to withstand the pressure, the use of steel frame as a wooden mold support system, with steel pipe as a support system used in the bolt fasteners, etc., how much money Ton. How much is a fastener, the above is not used in the construction industry used in the external scaffolding, stressed! The Is the kind of support system as a wood template! Please give the professionals a detailed answer! There is the price, that place to sell? The

- Pad wood template should be called I-shaped steel bar, there are several other names of steel "H-beam, T-beam, I-shaped steel, channel, angle" like these large steel market are sold

- Q:How to prevent the template support collapsed

- The third is to increase the supervision of the construction of high template. Local construction departments should actively promote the grid management, a clear focus on regional monitoring and key areas. For large templates and other dangerous projects, should increase the frequency of inspection, found that timely supervision and rectification, effectively curb the occurrence of major accidents.

- Q:How the engineering quantity of the square wood supporting the template in the construction project is calculated

- If it is to do the construction budget may not count, the quota can be set out. But from the construction technology point of view, to do the plan need to mention, more of the less and not. So according to your template to determine the program, one by one is the correct way out. To be wrong, the individual boss does not kill you blame.

- Q:Template support did not stand good, how to remedy the lower floor?

- The sinking of the local template demolition, concrete smashed, re-playing concrete, although not in line with the provisions, but the project often do so, you know

- Q:There are experts to demonstrate the high-support model, the template support frame erected there is no requirement must be held by the shelves of special operations card can be erected carpenters can not erect a search

- Must be held by the shelves of special operations card can be erected

- Q:The problems of improper matching of template supporting system and preventive measures

- (1) support the optional sloppy, without a security check, no enough carrying capacity and stiffness, deformation of concrete after casting template. (2) support stability is poor, no guarantee measures, concrete pouring support their own instability, so that deformation of the template.

- Q:Building template support system force calculation? Is to calculate the support system can withstand the upper pressure!

- There is a PKPM software (CMIS), there are inside. Just enter the parameters and automatically generate the calculations. I suggest you can try. We are all using this. Including the external scaffolding, unloading platform design force calculation can be used.

- Q:In addition, for example, in the 30-meter-high pier body pouring continuous beam 0 # block, beam 0 # block can be used to support the bracket (usually block 0 block will be surrounded by the entire pier), but 30 meters high Of the scaffolding if not connected with the bracket, then what is the way to make the stability of scaffolding requirements? Is it only anchoring? Please master answer.

- Scaffolding specification is JGJ130-2010 "construction of fasteners steel scaffold safety technical specifications." Scaffolding structure, the principle of calculation is self-contained bearing capacity, stable system; template bracket specification is JGJ162-2008 "building construction template safety technical specifications", also self-independent load capacity, stable system.

- Q:400 thick concrete roof template support system need expert demonstration?

- We can increase the column density can be appropriate. Do not need to use expert argument.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Economic Single Side Bracket for Retaining Wal

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords