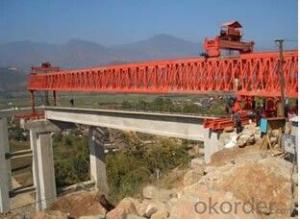

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

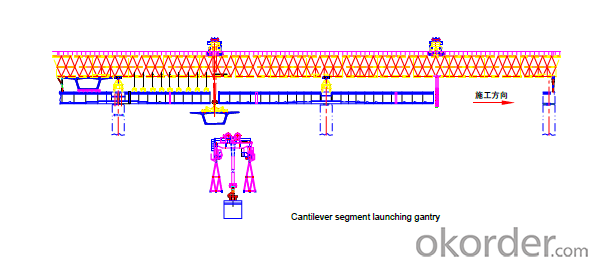

Cantilever segment launching gantry

The launching gantry is used to put the pre-fabricated segment

onto the pre-fabricated pier. It is a kind of crane with the main

function of lifting and transfer the segment to designated

position, but very different from the common crane. It’s more

strict than the common one and can be walked on. Launching

gantry can be divided into several kinds such as launching

gantry for highway, for common railway and for passengerdedicated

line, etc..

◆ Equiped with protection system which guarantee the absolute safety during working. It’s safe, easy

and practical.

◆ Easy installation and removal

◆ Safe & easy operation, easy fixing, and safty during walking

◆ Simple structure, clear big operational space and high efficient.

- Q:Such as Title ah.....I am sorry that the steel structure

- 84798990 double beam bridge machine84798990 Longmen bridge erecting machine84798990 science and technology extension type double guide beam bridge machine84798990 special type Longmen bridge erecting machine84798990.90 bridging machine86040099 bridging machineI agree that your description is too simple, how to give you the appropriate coding? Best picture ah

- Q:Weight of 120 ton bridging machine

- 0.65m/min (40 m and 120 tons beam) - 0.75m/min (30 m and 100 tons beam) 0.95m/min (30 m, 80 tons beam), the vertical speed of the crane: 6.6m/min 7, crane cross.

- Q:Bridge erection of a small box girder of long time

- It depends on the length of your box girder

- Q:Self-propelled bridge erecting machineMore than 80 tons of self erecting machine price is about how muchKnow the trouble to provide point information!

- The main structure of the hollow box girder, rigid, so the reduction of great magnitude, aspect of stable operation and the operation mechanism can be arbitrary 360 degree turn, orthogonal, can be set up in any direction and angle of skew bridge. Compared with the prior art, the machine has the advantages of light weight, short body lifting ability

- Q:Bridge erecting machine belongs to bridge or gantry crane

- Bridge crane is a crane, because its main function is to lift the beam, and then transported to the location and put down. But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q:Detection and quality standard of bridge erecting machine

- This type of bridge machine can not be self, need to push the locomotive. The forearm is used for hanging beam, and the rear arm is balanced, and the front and rear arms can not swing in the horizontal plane. When the bridge is built, it is often necessary to use a special 80 ton Xiaoping car to transport the beam to the hanging arm of the bridging machine, which is called "feed beam". Bridge crane will lift the beam, the axle load increases, and the bridge of the new embankment is relatively soft, therefore, the bridge crane crane beam must take reinforcement measures, such as the use of heavy car road, add sleeper, etc..

- Q:Purchase of special equipment, the use of units of evidence is the use of special equipment license?Where is the place of use or production?

- Detailed telephone to consult your local 114, or you tell me, I help you ask.

- Q:How long will it take to set up the 30 - meter girder erecting machine on the highway

- Erection of 30 m girder bridge machine total length of 56-58 meters

- Q:I would like to ask what types of bridge machine

- In addition, there is a large project is used, such as the Hangzhou Bay Bridge (1800 tons), Su Tong Bridge (how many tons I do not remember.) Such as the use of highway bridge crane tonnage is very large, where the bridge assembly is generally segmental assembly, there is little in the form of a whole hole.So, you ask what kind of bridge machine model, it is difficult to say, because the product itself is a non-standard product, each manufacturer can have their own unique way to distinguish the name.

- Q:What are the conventional lifting equipment? Bridge erecting machine is a kind of lifting equipment

- A device that is especially large in weight, or a volume of earth objects, such as lifting the house and moving the equipment. In the hoisting machinery category, there is a market called unconventional lifting equipment, generally refers to the general is lifting the weight or volume of the earth is particularly large, objects, such as lifting and moving equipment housing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Easy Operation Cantilever Segment Launching Gantry

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords