E-glass Fiberglass Woven Roving,400g,1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

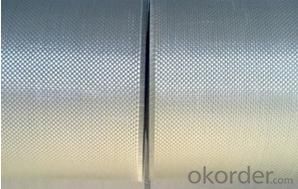

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q:How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue is used in the production of agricultural equipment as a reinforcing material. It is typically applied to the surface of the equipment, such as tractor bodies or storage tanks, to provide strength, durability, and resistance to environmental elements. The fiberglass mat tissue helps in enhancing the structural integrity of the equipment, making it more reliable and long-lasting for agricultural applications.

- Q:Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant.

- Q:How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue stands out as an insulation material with distinct characteristics and benefits when compared to other options. To begin with, its thermal insulation properties are remarkable. With its low thermal conductivity, it effectively minimizes heat transfer between the inside and outside of buildings. As a result, it helps maintain cooler temperatures in summer and warmer temperatures in winter, leading to energy savings and enhanced comfort. Moreover, fiberglass mat tissue excels in sound insulation. It effectively reduces noise transmission through walls and floors, creating a calm and peaceful indoor environment. This is particularly advantageous in commercial buildings, where noise reduction plays a vital role in productivity and customer satisfaction. Notably, fiberglass mat tissue is lightweight and flexible, making it easy to handle and install. It can be easily tailored to fit around obstacles such as pipes and ducts, ensuring a tight and efficient insulation barrier. This simplifies installation, saving time and labor costs during construction or renovation projects. Another significant advantage of fiberglass mat tissue is its fire resistance. As a non-combustible material, it does not contribute to the spread of fire. This is especially crucial in buildings prioritizing fire safety, such as hospitals, schools, and residential properties. Furthermore, fiberglass mat tissue is durable and long-lasting. It does not degrade or lose its insulation properties over time, guaranteeing consistent energy efficiency and performance for many years. This durability makes it a cost-effective choice, reducing the need for frequent replacement or maintenance. Lastly, fiberglass mat tissue is environmentally friendly. It is manufactured using recycled glass and sand, decreasing the demand for raw materials. Additionally, it is recyclable at the end of its lifespan, reducing waste and promoting sustainability. In conclusion, fiberglass mat tissue offers exceptional thermal and sound insulation, effortless installation, fire resistance, durability, and environmental benefits. While other insulation materials may present their own advantages, fiberglass mat tissue remains a versatile and reliable option for diverse applications.

- Q:Can fiberglass mat tissue be used for architectural applications?

- Certainly! Fiberglass mat tissue is applicable for architectural purposes. This versatile material offers numerous advantages when utilized in architectural undertakings. It functions predominantly as a reinforcement material for the construction of architectural components such as roofs, facades, and walls. The principal benefit of fiberglass mat tissue for architectural use lies in its exceptional strength-to-weight ratio. It provides outstanding structural integrity while remaining lightweight, rendering it highly suitable for extensive architectural ventures. Moreover, fiberglass mat tissue exhibits durability and resistance against severe weather conditions, enabling its application both indoors and outdoors. Furthermore, fiberglass mat tissue possesses commendable fire resistance attributes, a vital aspect in adhering to architectural safety standards. With a high melting point and the absence of flame propagation, it proves to be a dependable choice for fire-resistant applications. In terms of aesthetics, fiberglass mat tissue can be effortlessly molded into various shapes and designs, granting architects the freedom to explore creative possibilities. It can be painted or coated to achieve the desired visual appearance, thus establishing its versatility as an architectural finishing material. In conclusion, fiberglass mat tissue emerges as a trustworthy and adaptable material suitable for diverse architectural projects. Its strength, durability, fire resistance, and aesthetic flexibility make it an ideal choice for a wide spectrum of architectural applications.

- Q:Can fiberglass mat tissue be used for making insulation boards?

- Yes, fiberglass mat tissue can be used for making insulation boards. The tissue provides strength, stability, and reinforcement to the insulation material, making it an effective choice for insulation board manufacturing.

- Q:What are the potential limitations of using fiberglass mat tissue?

- Using fiberglass mat tissue comes with several potential limitations. To begin with, fiberglass mat tissue tends to be more brittle compared to other materials. This means that it may crack or break easily under certain conditions, especially if it is subjected to high levels of stress or impact. This brittleness can restrict its use in applications where durability and flexibility are important. Moreover, fiberglass mat tissue is not naturally resistant to moisture. If it is exposed to water or high humidity for extended periods, it can absorb moisture and lose its structural integrity. Consequently, it may not be suitable for use in environments where moisture resistance is crucial. In addition, working with fiberglass mat tissue can be challenging due to its sharp edges and fibers. Taking special precautions such as wearing protective clothing and using proper handling techniques is necessary to avoid injury. This can add complexity and cost to the use of fiberglass mat tissue in certain applications. Furthermore, cutting or manipulating fiberglass mat tissue can release fine particles or fibers into the air. Inhaling these particles can pose health risks, potentially leading to respiratory issues or irritation. To minimize these risks, it is essential to take proper safety measures such as using masks and ensuring adequate ventilation. Lastly, fiberglass mat tissue is relatively expensive compared to some alternative materials. Its production process involves multiple steps and specialized equipment, which contributes to higher costs. As a result, its use may be limited in applications where cost-effectiveness is a primary concern. In conclusion, while fiberglass mat tissue offers various advantages in terms of strength, insulation, and fire resistance, it is crucial to carefully consider its potential limitations before choosing it for a specific application.

- Q:Can fiberglass mat tissue be used for reinforcing fiberglass pools?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass pools. It helps enhance the strength and durability of the pool structure by providing added reinforcement to the fiberglass layers.

- Q:What is fiberglass mat tissue made of?

- Fine strands of glass fibers are used to create fiberglass mat tissue, which is a flexible material resembling fabric. The glass fibers are usually produced by melting glass and transforming it into thin filaments. These filaments are then coated with a binding agent to enhance their strength and durability. The woven composition of the fiberglass mat tissue contributes to its ability to reinforce and stabilize different materials and products. This makes it a suitable option for insulation, roofing, and composite materials.

- Q:Does fiberglass mat tissue provide good acoustical performance?

- Good acoustical performance is provided by fiberglass mat tissue. This material, composed of fine glass fibers, effectively absorbs sound waves and reduces echo and reverberation in a space. It possesses outstanding sound absorption properties, making it suitable for use in construction, automotive, and aerospace industries. The ability of fiberglass mat tissue to dampen sound and enhance acoustics makes it a favored option for soundproofing walls, ceilings, and floors in buildings. Moreover, its lightweight nature and ease of installation further contribute to its appeal for acoustical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Woven Roving,400g,1600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords