E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Cloth Description:

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

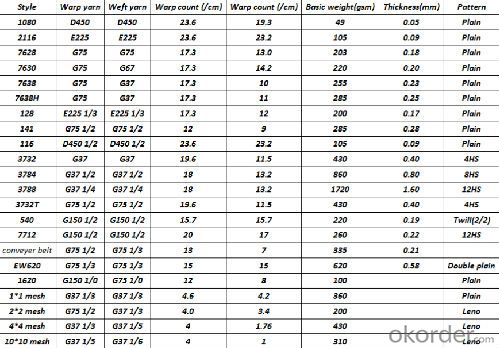

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass fabrics be used for sports or recreational equipment?

- Yes, fiberglass fabrics can be used for sports or recreational equipment. They are commonly used in the manufacturing of various sports equipment such as kayaks, canoes, surfboards, skis, and even hockey sticks. The high strength-to-weight ratio and durability of fiberglass fabrics make them an ideal choice for these applications, as they contribute to the overall performance and longevity of the equipment. Additionally, fiberglass fabrics can be molded into complex shapes, allowing for greater design flexibility in creating efficient and reliable sporting gear.

- Q:Are fiberglass fabrics suitable for use in the agricultural industry?

- Yes, fiberglass fabrics are suitable for use in the agricultural industry. They offer various benefits such as exceptional strength, durability, and resistance to chemicals, pests, and environmental elements. Fiberglass fabrics can be used for crop protection, greenhouse construction, animal housing, and other agricultural applications.

- Q:Is fiberglass fabric resistant to UV degradation in outdoor applications?

- Yes, fiberglass fabric is highly resistant to UV degradation in outdoor applications. Fiberglass fabric is made from fibers that are manufactured to withstand prolonged exposure to sunlight and other environmental factors. The fabric is treated with special coatings or finishes that provide additional protection against UV radiation. This UV resistance makes fiberglass fabric an ideal choice for outdoor applications where exposure to sunlight is a concern, such as in awnings, canopies, and outdoor furniture. Additionally, fiberglass fabric maintains its strength and integrity even after years of exposure to UV rays, ensuring its long-lasting performance in outdoor settings.

- Q:Can fiberglass fabric be used for insulation in construction projects?

- Indeed, insulation in construction projects can utilize fiberglass fabric. Constructed from interwoven glass fibers, this material boasts remarkable thermal insulation capabilities. It finds extensive application in walls, roofs, and floors, effectively impeding heat transfer and enhancing energy efficiency within buildings. Its lightweight nature, flexibility, and ease of installation contribute to its widespread adoption in construction endeavors. Moreover, fiberglass fabric's resistance to fire, moisture, and chemicals renders it a sturdy and enduring insulation material.

- Q:How is fiberglass fabric cut and shaped?

- Fiberglass fabric is typically manipulated and shaped through various techniques. One method commonly employed is the utilization of scissors or a utility knife to achieve the desired size and shape. This method is frequently employed for smaller or more intricate cuts. For larger cuts or more precise shaping, the technique known as "hot knife cutting" is often utilized. This involves the use of a heated blade or wire to neatly slice through the fiberglass fabric. The application of heat aids in sealing the fabric's edges, averting fraying and guaranteeing a sleek finish. Another technique employed for shaping fiberglass fabric involves molding. In this process, the fabric is positioned over a mold or form and an adhesive or resin is administered to secure it in place. Subsequently, the fabric is allowed to cure or harden, acquiring the mold's shape. This method is commonly employed in the manufacturing of fiberglass products such as boat hulls or automotive parts. In conclusion, the precise cutting and shaping of fiberglass fabric necessitates careful attention to detail. Whether employing scissors, a hot knife, or molding techniques, it is imperative to achieve clean cuts and proper shaping in order to attain the desired outcome.

- Q:Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Indeed, reinforcement in underground storage tanks can be achieved through the utilization of fiberglass fabric. Renowned for its exceptional corrosion resistance and high strength-to-weight ratio, fiberglass fabric emerges as an optimal selection for this purpose. The incorporation of fiberglass fabric not only enhances the structural integrity of the tank but also mitigates the risk of potential failures or leaks. Additionally, the ease of handling and installation of fiberglass fabric renders it a practical and cost-efficient solution for reinforcing underground storage tanks.

- Q:Can fiberglass fabric be used for air ducts?

- Yes, fiberglass fabric can be used for air ducts. It is a common material used in HVAC systems for its insulation properties and durability. Fiberglass fabric helps to maintain temperature control and prevents air leakage in ductwork, making it suitable for air duct applications.

- Q:What material can be used instead of fiberglass cloth?

- It is a glass glass fiber cloth woven by high temperature after snagging. Its product stability is very high, tensile strength is also unmatched by non-woven fabrics. And the fiberglass cloth decorative wall also has the permeability. Therefore, the two products are not interchangeable.

- Q:What does "PCB" mean?

- We can't transmit electrical signals just as insulation plates, so we need to cover the surface with copper. So we call the PCB board a copper clad substrate. In the factory, the common copper substrate in this code is FR-4, each card manufacturers which in general there is no difference, so we can think of everyone at the same starting line, of course, if it is best to use high frequency board, copper clad PTFE glass cloth laminate high cost. The process of copper is very simple, generally can be made by rolling and electrolytic solution, the so-called rolling is Gao Chundu (>99.98%) of the copper rolling method on the PCB substrate, because the adhesive has excellent epoxy resin and copper foil, copper foil adhesive strength and high working temperature, can be no bubble dip in the molten tin is 260 DEG C in. This process is like rolling dumpling wrappers, but the dumpling wrappers are thin and thin. The thinnest is less than 1mil (industrial unit: mil, 1/1000 inches, equivalent to 0.0254mm)! If the dumpling wrappers are so thin, the pot must leak! The so-called electrolytic copper in junior high school chemistry has learned, CuSo4 electrolyte can continuously manufacture a layer of "copper foil", this is more easy to control the thickness, the longer the copper foil the more thick! Usually the factory has strict requirements on the thickness of copper foil, usually between 0.3mil and 3mil, and has a dedicated copper foil thickness tester to test its quality. Like old radios and amateur PCB, copper is especially heavy, and the quality of the factory is far worse than the computer board.

- Q:Is fiberglass fabric the same as mesh cloth?

- Glass fiber mesh is a kind of glass fiber cloth.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords