E GLASS FIBER WOVEN ROVING FOR BOAT PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

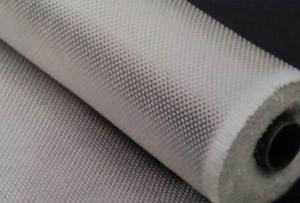

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1) Woven roving is a kind of evenly distributed material which owns high strength on both side with high intensity, the fiber content and strength is even higher during the production of FRP products.

2) Benefit from the production procedure and the material itself, the fabric maintains high percentage of its material strength, and also very easy for the resin to penetrate.

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs will answer all your inquiries at first time..

3. All our products have warranties.

4. Offering the support to solve the problem during the application or selling period.

5. Good quality with competitive price.

6. The same quality of samples and mass products is granted.

- Q:What is the weight of fiberglass mat tissue per square meter?

- The weight of fiberglass mat tissue per square meter can vary depending on the specific product and manufacturer. However, on average, fiberglass mat tissue typically weighs around 100-300 grams per square meter.

- Q:What is the moisture resistance rating of fiberglass mat tissue?

- The moisture resistance rating of fiberglass mat tissue may differ depending on the specific product and manufacturer. Nonetheless, fiberglass mat tissue is renowned for its exceptional moisture resistance properties. It is typically engineered to exhibit high resistance against water absorption, rendering it suitable for applications where moisture exposure is a concern. This moisture resistance attribute aids in preserving the structural integrity and performance of the fiberglass mat tissue, even under humid or wet conditions. It is crucial to consider the manufacturer's provided product specifications to ascertain the precise moisture resistance rating when selecting fiberglass mat tissue for a particular application.

- Q:How is fiberglass mat tissue used in the production of composite panels?

- Due to its unique properties and versatility, fiberglass mat tissue is commonly utilized in the manufacturing of composite panels. Its role as a reinforcement material contributes to the enhancement of strength, durability, and overall performance of these panels. In the production process, a sandwich structure is typically formed by incorporating fiberglass mat tissue between layers of resin. This tissue serves as a reinforcing layer, providing added strength and stability to the panels. It effectively distributes applied stress evenly across the panel, thereby reducing the likelihood of cracks or fractures. One notable advantage of fiberglass mat tissue is its ability to enhance the impact resistance of composite panels. By absorbing and dispersing energy when subjected to external forces, it diminishes the risk of damage or breakage. This characteristic makes it a highly suitable choice for applications that necessitate high impact resistance, such as automotive parts, boat hulls, or aircraft components. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion, making it appropriate for usage in environments with high humidity or exposure to chemicals. It acts as a protective barrier, shielding the composite panels from moisture and corrosive substances. As a result, the panels enjoy an extended lifespan and sustained performance. Moreover, fiberglass mat tissue possesses exceptional moldability, which facilitates the creation of intricate shapes and designs. It can be effortlessly molded into various forms, thus offering flexibility in the production process and enabling the fabrication of customized composite panels tailored for specific applications. In summary, fiberglass mat tissue is a vital component in the manufacturing of composite panels. It reinforces the structure, enhances impact resistance, improves corrosion resistance, and enables design flexibility. Its unique properties have made it a favored choice in industries such as construction, transportation, aerospace, and marine, where the demand for high-performance and long-lasting composite panels is prevalent.

- Q:Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. It is a versatile material that offers excellent mechanical strength, durability, and corrosion resistance. It can be used for various applications in railway infrastructure, including reinforcement of concrete structures, insulation, and protection against fire hazards. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a cost-effective choice for railway projects.

- Q:What are the main applications of fiberglass mat tissue?

- Fiberglass mat tissue is a versatile material that finds various applications in industries such as construction, automotive, aerospace, and marine. Some of the main applications of fiberglass mat tissue include: 1. Construction: Fiberglass mat tissue is commonly used in the construction industry for reinforcing and strengthening various building materials such as roofing shingles, wallboards, and cementitious products. It adds tensile strength and durability to the structures, making them more resistant to cracks, water damage, and weathering. 2. Automotive: Fiberglass mat tissue is used in the manufacturing of automotive parts such as dashboards, door panels, and trunk liners. It provides structural integrity, sound insulation, and heat resistance, making the vehicles safer and more comfortable. 3. Aerospace: In the aerospace industry, fiberglass mat tissue is used in the production of lightweight composite materials used in aircraft structures. It helps in reducing the overall weight of the aircraft, improving fuel efficiency, and enhancing its performance. 4. Marine: Fiberglass mat tissue is widely used in boat and shipbuilding. It is used in the construction of hulls, decks, and other components to provide strength, stiffness, and resistance to water and corrosion. Fiberglass mat tissue is preferred over traditional materials like wood due to its lightweight, durability, and low maintenance requirements. 5. Electrical and Electronics: Fiberglass mat tissue is used in electrical insulation applications such as transformer boards, electrical cabinets, and switchgear. It provides excellent dielectric properties, heat resistance, and mechanical strength, ensuring the safety and reliability of electrical equipment. 6. Filtration: Fiberglass mat tissue is used in various filtration applications such as air filters, water filters, and oil filters. It acts as a filtration media, trapping and removing impurities, dust, and particles from the air, water, or oil, thus improving the quality and purity of the filtered substances. Overall, fiberglass mat tissue is a widely used material in numerous industries due to its strength, durability, lightweight, and resistance to various environmental factors. Its versatility makes it an essential component in various applications, contributing to the development of safer, stronger, and more efficient products.

- Q:Can fiberglass mat tissue be used for composite pipe manufacturing?

- Fiberglass mat tissue is indeed applicable for the manufacturing of composite pipes. It is a reinforcement material commonly employed in the production of composite pipes. By providing strength and durability, it renders the pipes suitable for a wide range of applications. Typically, the fiberglass mat tissue is impregnated with a resin, such as polyester or epoxy, thereby facilitating the binding of the fibers to form a solid structure. This reinforcement material is renowned for its lightweight properties and exceptional resistance to corrosion, making it a highly desirable option for composite pipe manufacturing. Moreover, it can easily be molded into various shapes and sizes, allowing for the production of pipes with different diameters and lengths. As a whole, the utilization of fiberglass mat tissue in composite pipe manufacturing brings about numerous benefits, including increased strength, durability, and resistance to severe environmental conditions.

- Q:Can fiberglass mat tissue be used for insulating radiant floors?

- Yes, fiberglass mat tissue can be used for insulating radiant floors. It is an effective insulation material that helps to minimize heat loss and improve energy efficiency in radiant floor heating systems.

- Q:Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

- Q:Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q:Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E GLASS FIBER WOVEN ROVING FOR BOAT PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords