E-glass Chopped Strand Mat Emulsion/300g/450g/600g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-glass Chopped Strand Mat Emulsion/300g/450g/600g

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

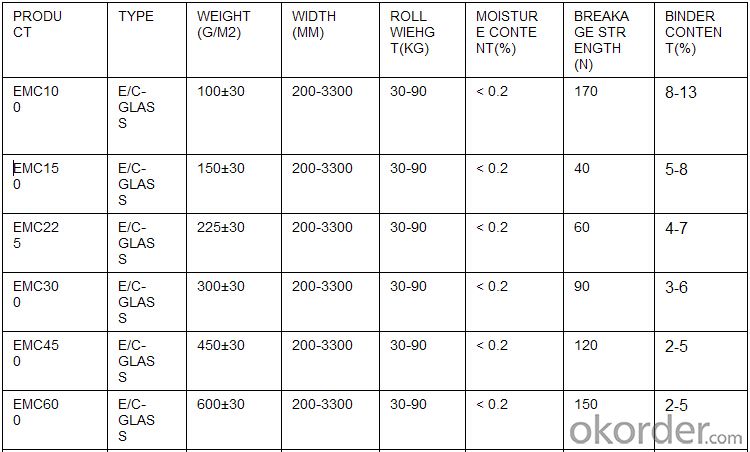

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:Can fiberglass mat tissue be used for interior decoration?

- Fiberglass mat tissue is an excellent option for interior decoration. This versatile material serves multiple purposes and is commonly utilized as a reinforcement for composite materials like fiberglass reinforced plastic (FRP). These materials are often employed to create decorative elements such as panels, wall coverings, and moldings. The fiberglass mat tissue offers a lightweight and durable solution with exceptional strength and resistance to moisture and chemicals. Moreover, it can be easily molded into various shapes and designs, making it a favored choice for interior decoration projects. Furthermore, the fiberglass mat tissue can be coated or painted to match any desired color or texture, enabling a wide array of creative possibilities in interior design.

- Q:What is the density of fiberglass mat tissue?

- The density of fiberglass mat tissue typically ranges from 0.3 to 0.6 grams per cubic centimeter (g/cm³).

- Q:How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue is used in the production of water tanks to provide reinforcement and durability. It is applied as a layer between the inner and outer walls of the tank to enhance its structural integrity and prevent leakage. The fiberglass mat tissue acts as a barrier against corrosion, increases the tank's resistance to external factors such as temperature changes and chemicals, and improves its overall strength.

- Q:Can fiberglass mat tissue be used for bridge deck rehabilitation?

- Indeed, bridge deck rehabilitation can utilize fiberglass mat tissue. Known for its exceptional strength and durability, this versatile material is commonly employed in construction endeavors, including the restoration of bridge decks. Its primary function is to reinforce and fortify existing structures. Bridge deck rehabilitation encompasses the process of rectifying and rejuvenating a bridge deck that has undergone deterioration over time. Typically, this procedure necessitates the removal of damaged concrete, the application of a fresh concrete layer, and the reinforcement of said layer with materials like fiberglass mat tissue. The utilization of fiberglass mat tissue as a reinforcement material in bridge deck rehabilitation is widespread due to its exceptional mechanical properties. Its high tensile strength plays a vital role in augmenting the load-bearing capacity of the bridge deck. Moreover, its corrosion resistance is especially crucial for bridge decks exposed to harsh weather conditions and chemicals. Additionally, fiberglass mat tissue is easily installed and adaptable to bridge decks of varying shapes and sizes. It can be embedded into the new concrete layer during the construction process or applied as an overlay onto the existing deck. This flexibility renders it an ideal choice for bridge deck rehabilitation projects. In conclusion, fiberglass mat tissue is, indeed, an appropriate material for bridge deck rehabilitation. Its robustness, endurance, and corrosion resistance make it an effective reinforcement material for repairing and fortifying bridge decks. Furthermore, its straightforward installation process and versatility further enhance its suitability for this specific application.

- Q:Is fiberglass mat tissue suitable for construction applications?

- Indeed, fiberglass mat tissue proves to be a fitting material for construction purposes. Renowned for its robustness, longevity, and ability to withstand diverse environmental conditions, this versatile substance is frequently employed in roofing, flooring, insulation, and wall panel installations. Fiberglass mat tissue emerges as an exceptional selection for construction ventures as it bestows reinforcement and stability upon a range of materials. When incorporated into roofing materials, it fortifies them against impacts, weathering, and fires. Similarly, it bolsters the strength and durability of flooring systems, rendering them capable of withstanding substantial loads and heavy foot traffic. Moreover, fiberglass mat tissue exhibits commendable insulation capabilities. It serves as an efficacious insulating component for walls, ceilings, and floors, enabling the maintenance of a comfortable indoor temperature while diminishing energy consumption. Its thermal and acoustic insulation properties render it an ideal choice for construction applications. Furthermore, its imperviousness to moisture, chemicals, and corrosion makes fiberglass mat tissue a suitable option for deployment in areas characterized by high humidity or exposure to harsh chemicals. Thanks to its resistance to decay, it guarantees durability, ensuring longevity in construction projects. To conclude, fiberglass mat tissue is an apt choice for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its adaptability and reliability have cemented its popularity within the construction industry.

- Q:Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q:Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. It is commonly used for reinforcing and strengthening automotive parts such as body panels, hoods, and bumpers. The fiberglass mat tissue provides excellent strength, impact resistance, and durability, making it a reliable choice for automotive use.

- Q:What are the potential limitations of using fiberglass mat tissue?

- Using fiberglass mat tissue comes with several potential limitations. To begin with, fiberglass mat tissue tends to be more brittle compared to other materials. This means that it may crack or break easily under certain conditions, especially if it is subjected to high levels of stress or impact. This brittleness can restrict its use in applications where durability and flexibility are important. Moreover, fiberglass mat tissue is not naturally resistant to moisture. If it is exposed to water or high humidity for extended periods, it can absorb moisture and lose its structural integrity. Consequently, it may not be suitable for use in environments where moisture resistance is crucial. In addition, working with fiberglass mat tissue can be challenging due to its sharp edges and fibers. Taking special precautions such as wearing protective clothing and using proper handling techniques is necessary to avoid injury. This can add complexity and cost to the use of fiberglass mat tissue in certain applications. Furthermore, cutting or manipulating fiberglass mat tissue can release fine particles or fibers into the air. Inhaling these particles can pose health risks, potentially leading to respiratory issues or irritation. To minimize these risks, it is essential to take proper safety measures such as using masks and ensuring adequate ventilation. Lastly, fiberglass mat tissue is relatively expensive compared to some alternative materials. Its production process involves multiple steps and specialized equipment, which contributes to higher costs. As a result, its use may be limited in applications where cost-effectiveness is a primary concern. In conclusion, while fiberglass mat tissue offers various advantages in terms of strength, insulation, and fire resistance, it is crucial to carefully consider its potential limitations before choosing it for a specific application.

- Q:How does fiberglass mat tissue perform in terms of moisture absorption?

- Fiberglass mat tissue performs exceptionally well in terms of moisture absorption. Due to its composition of multiple layers of glass fibers and a binder, it can effectively resist moisture penetration, making it highly resistant to water absorption. This property makes fiberglass mat tissue an ideal material for various applications where moisture resistance is crucial, such as in roofing, insulation, and composite manufacturing.

- Q:Is fiberglass mat tissue resistant to mildew and rot?

- Indeed, the resistance of fiberglass mat tissue to mildew and rot is undeniable. Crafted from delicate glass fibers interlaced to form a robust and enduring substance, fiberglass stands as a paragon. Its non-porous nature prevents moisture absorption, thus endowing fiberglass mat tissue with exceptional resistance against mildew proliferation and rot-induced decomposition. Moreover, fiberglass often receives protective coatings or additives that amplify its fortitude against these biological detriments. For this reason, fiberglass mat tissue emerges as an exemplary selection in settings where humidity or moisture pose a threat, such as bathrooms, outdoor structures, or regions prone to elevated humidity levels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Chopped Strand Mat Emulsion/300g/450g/600g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords