Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

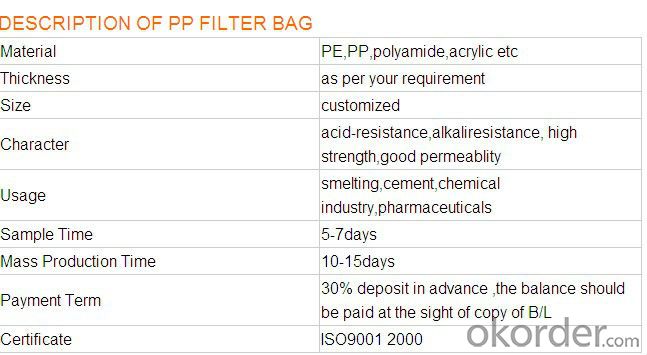

1. Description of Non woven Fiberglass Dust Filter Bag Dust Collector

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Non woven Fiberglass Dust Filter Bag Dust Collector

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Non woven Fiberglass Dust Filter Bag Dust Collector

Weight(g/m2) | 500~550 | |

Thickness(mm) | 2.3~2.5 | |

Air permeability(m3/ m2/min) | 14~8 | |

Tension at break (N/5×20cm) | Warp | >900 |

Weft | >1200 | |

Elongation at break (%) | Warp | <35< span=""> |

Weft | <50< span=""> | |

Working temperature (℃) | Continuous | 130 |

Instantaneous | 150 | |

Anti-acid | Good | |

Anti-alkali | Common | |

Anti-abrasion | Good | |

Post treatment | Thread burning,surface smoothing or coating etc | |

4. Application fields

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

5. Images of Non woven Fiberglass Dust Filter Bag Dust Collector

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q:What materials are commonly used in liquid filtration bags?

- 1, good heat resistance, can be used under 280 ℃ for a long time Dust is easy to peel off The dimension stability is good, the fiberglass itself does not contract at the standard temperature

- Q:What is a good filter bag?

- For lower material length to be less than 10mm, the surrounding is quilted. When sewing cloth bags, the bag is not less than 15 needles every 10 centimetres, not less than 12 stitches per 10cm. Finally, in the process of sewing, the filter bag can not be damaged or leak.the diameter is greater than 20 centimeters and the length is greater than 5 meters.

- Q:What do you notice when the filter bag and dust collector are installed?

- To prevent the damage of the cloth bags, ask for each sack to be packed, and pack a dust collector.

- Q:What are the textures of the liquid filter bag

- Polyester fiber (polyester, PE) : special polyester fiber has good performance under normal temperature and is the main filter in bag filter. But under dry conditions through operating temperature 130 ℃; Continuous working at above 130 ℃ harden; Fade; Being brittle, the temperature also weakens the strength. Range of accuracy: 1-300 microns.

- Q:Choose what aspects to consider when choosing a filter bag

- Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter. The inside of the filter bag is used to support the filter bag to prevent the bag from collapsing, and it helps to clear and redistribute the dust cake.

- Q:Problem with the washing machine filter bag

- All this is not the problem of washing machine, washing machine filter can filter tiny fiber. The problem in the quality of a material of clothes. There is a special love of clothes stick cotton fiber, can only be washed separately, could not have other moves.

- Q:What is the effect of a dust filter bag?

- The dust is attached to the outer surface of the filter bag. Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter.

- Q:How to maintain the filter bag?

- The daily maintenance and maintenance of dust filter bags as the heart of cloth bag dust collector is very important to prolong the life of bagged dust collector. Dust can be discharged because of the initial layer, damage or failure of the filter bag. 1, if the dust collector of excess emissions cut filter operation pressure is lower than design a lot of time, could be a bag of initial layer is insufficient, may be due to the high bag when filtering velocity, high injection pressure of compressed air, or the filter bag cleaning cycle short, etc. In this case, the cleaning cycle of the cloth bag should be set to the maximum time, and the pressure social stability of the outlet pressure of the dust collector should be improved. But if the collector is discharged after cleaning the bag, it should be examined if the pressure of compressed air is too great.

- Q:How do you clean a filter bag with oil stains?

- Clear the dust filter bag with oil: using high frequency vibration, will enter the dust filter bag inside the wall of the larger dust particles removed, will not affect fiber entanglement of fastness, keep the filter bag is good, easy tear of dirt. Chemical experiment treatment: extract the bag samples, using the professional instrument laboratory detection filter filter bag oil composition, to adapt to washing raw materials, the maximum cleaning filter bag and without causing any damage to the filter bag.

- Q:What are the benefits of using a filter bag

- Secondly, the filter bag is made of advanced technology, it is not the phenomenon of the needle eye and it is very good.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords