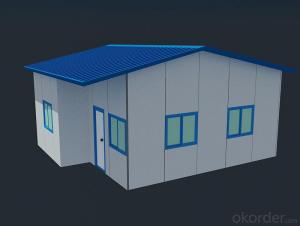

Durable EPS House

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed introduction to EPS house:

1 Structure is reliable :Light steel structure system is safe and reliable ,satisfied modern architecture concept.

2 Easy assembly and disassembly : The house can be assembled and disassembled many times,used repeatedly. It just need simple tools to assemble .each worker can assemble 20-30 square meters every day ,6 worker can finish 300 sqm prefab house in 2 days.

3 Beautiful decoration : the prefab house is beautiful and grace ,have bright and bland colour , flat and neat board , with good decoration effect.

4 Flexible layout : Door and window can be assembled in any position , partition wall panel can be assemble in any transverse axes sites ,stair is assembled in outside.

5 Using life : All the light steel structures have antisepsis-spraying treatment.the normal using age are above 15 years.

6 Environmental protection and economy : Prefab house design is reasonable, easy to assemble and disassemble,used circularly,low wastage,without building rubbish. Average using costing is less than other kinds of building annually.

ITEM | SANDWICH PANEL | LENGTH THICKNESS | 950MM 50MM | ||||||

QUANTITY | 1M2 | DATE | 2013-12-4 | ||||||

ITEM | STANDARD | RESULT | MEMO | ||||||

| 1 | COLOR | Conformity in same batch | Conformity | Qualified | ||||

2 | CRACK | No | No | Qualified | |||||

3 | INDENTATION | Not obviously | Not obviously | Qualified | |||||

4 | SIZE | LENGTH | ±2mm | 51mm | Qualified | ||||

THICKNESS | ±20mm | 950mm | Qualified | ||||||

5 | DENSITY kg/m2 | >=10.5% | 10.8% | Qualified | |||||

6 | STRIPPING PERFORMANCE | >=85% | 87% | Qualified | |||||

7 | MPA | >0.1 | 0.11 | Qualified | |||||

CONCLUSION | Qualified | ||||||||

| | | | | | | | | | |

Note:

1.Price no including the transport and installation cost, no including foundation cost,floor and ceiling cost,water and electricity cost.

2.Validity: This quotation sheet is valid for 15 days due to the unstable RMB exchange rate.

3.Payment term:30% T/T deposit before production, the balance 70% T/T need to pay before delivery.

4.Packing:Flat pack.

5.Delivery time:15 days after receive the 30% deposit. (The quantity is less than 5000㎡)

6.All price not listed in above project need to calculate separately.

- Q:Fuhan 18mmE0 grade sandwich panels how?

- Now are generally E1-class wood core board, and E1 grade Fuhan plate genuine goods, then environmental protection is the standard. E0 level of rare, and expensive

- Q:Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q:Color steel plate, color steel sandwich panels, clean color steel plate is the same thing? How much is the price?

- Color plate is veneer 0.4 mm about 23 yuan sandwich panel is a double color plate in the middle plus benzene plate on the 0.3 0.2 is about 45 yuan purification board is used in pharmaceutical plants, food purification plant hanging shed wall panels clean plate surface smooth The price is also expensive and more critical is what you want to do

- Q:in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q:Use the sandwich board to do the quotation of the wall how to do ah

- The board of the board is made of lightweight Polish special cement, EPS granule, expanded perlite, a variety of high-molecular light aggregate for core board, strong composite treatment made of lightweight partition plate

- Q:Is the polyurethane sandwich panel and foam board flame retardant?

- To see if there is no added flame retardant

- Q:I just got a polyurethane sandwich board production line, I would like to ask about making money!

- This you have not done looking at some adventure

- Q:What is the name of the glue used in the color steel composite board

- Most use of two-component polyurethane adhesive,

- Q:Color steel sandwich panels and C steel belongs to what industry

- Should be considered building materials it Make the house with the thing.

- Q:Paper honeycomb sandwich panels about how much the price

- Do not know what you do with, I see you most recently has been consulting honeycomb board problems, I do pp honeycomb board

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Durable EPS House

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords