Durable Click Lock Waterproof And Healthy Wood Texture PVC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

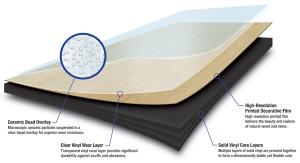

Name | 3mm Dark Limed Grey Oak Crystal Texture Vinyl Floor Colorful PVC Vinyl Flooring |

Color | We have several hundreds of colors to customers' option |

Thickness | 2mm, 2.5mm, 3.0mm, 4.2mm, 5.0mm are available |

Surface | More than 6 kinds of surfaces,such as Registered in Emboss, Antique Wood Texture, Crystal Texture, Pearl Structure, Carpenter Handscrape, Classic Slate and etc. |

Size | Different kinds of sizes to satisfy you |

Other Procedures | We provide PVC sheet making, Hot pressing, UV-coating, Annealing, Punching and Profiling, etc. |

Service | Perfect Quality Control System,VIP server solve your problem in time |

Innovation | R&D team develop new product or color weekly |

Payment | 30% deposit and 70% upon the copy of B/L |

Delivery Time | Within 40 days after receipt of your L/C from your bank or receiving the deposit |

Technical Data

Safety Criteria | Standard | Value | ||

Flammability | EN 13501-1 | Bf1 | ||

Slip resistance | EN13893 | DS | ||

Formldehyde Emission | EN717-1 | None | ||

Color Fastness | ISO 105-BO2 | ≥ 6 | ||

Castor Wheel Test | EN425 | Pass | ||

Performance | Standard | Value | ||

Wear Resistance | EN-660-2 | ≤ 0.015g | ||

Flexibility | EN435 | No damage | ||

Peel Resistance | EN431 | ≥ 2.8Kgf/50px | ||

Residual Indentation | EN434 | ≤ 0.1mm | ||

Curling After Exposure To Heat | EN434 | ≤ 1.2mm (80°C, 6hrs) | ||

Dimensional Stability | EN434 | ≤ 0.12% (80°C, 6hrs) | ||

How to install:

Vinyl tiles have always easy to install.but today's no-glue vinyl tile system are even easier.the tiles lock together at the edges to form the surface of the floor,with nothing attaching them to the subfloor, so you can lay them over any solid,flat aurface. Vinyl lock tiles,are formed to look like wood,with a patented locking system.

Instrctions:

1.Remove the floor trim fromt he perimeter of the floor with your hammer and prybar. Don't break it. Set it aside.

2. Lay the first row of this vinyl tiles alongside your starting wall, locking them together at the ends. Put shims between the tiles and the wall, to create a space that will allow for floor expansion. Lay all the full tiles that will fit.

3. Measure the space at the end of the first row of tiles. Use your utility knife to cut a tile to size, running the knife alongside a straight-edge to score it, and then snapping the tile. Lay it with the cut side facing the wall.

4. Lay the next courses of tiles alongside the first building out in courses. Start each course at the opposite end of the room as the previous course, so the ends of the tiles don't line up between courses. Lock the tiles together by their long edges,pushing them in at a downward angle, locking then, then dropping then into space. Cut the ends as necessary.

5. Cover the whole floor. Cut the final course of tiles length-wise, so they fit against the wall with a small gap there(about 1/4 inch).

6. Nail the floor trim back in place, using your hammer and finish nails, to seal off the spaces by the walls. Nail toe trim into the walls and not through the flooring.

Our Serivce

1. Various Designs & Complete FinishChic Vinyl serves customers with the widest range of PVC flooring on Dimensions, Surface Types,Color Patterns etc

2. OEM Production: We got a rich experience in OEM production.

3. Strict Quality Control System & Sunspeed Laboratory We make sure every plank from Sunspeed is perfect in every aspect.

4. In order to support clients requirement and cooperation, we have flexible payment terms,we accept the T/T, L/C, DP,DA etc.

5.Fast delivery time based on our large supply capacity, we can delivery the goods as customers’ requirement. Usually, we will spend 15-20 work days once we confirm the order.

6. Mature Aftersale and Feedback System Our mature system will guarantee the best quality of flooring after sales.

Why Choose Us

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Advantages:

1. With Unilin patent click design, esay for installation

2. Economic choose for Residential and Commercial.

3. Waterproof,anti-corrosion, anti-crack, anti-mould, anti-aging, long lifetime.

4. Eco-friendly, low carbon with no noxious or chemical components.

5. More than 10 years of warranty,recycled for reusage.

Show Room

- Q:The new rent a house, rough housing, house, do not want to decoration, but the cement really ugly, but the old feeling clean and fresh, a plastic carpet, feel the taste, said that before reading not made of plastic cloth, do not know whether to shop on the ground is also very harmful to me? Want to know now: plastic carpet and cement that is more harmful to human body?

- So take a look at the level of plastic carpet:The carpet is divided into six grades according to the different performance(1) light household level: placed in infrequently used rooms or parts;(2) medium grade or light grade: for master bedroom or dining room;(3) the general level of household or moderate professional use: used for living room, frequent traffic areas such as staircases, corridors, etc.;

- Q:How to eliminate the smell of plastic floor

- No special way to remove the taste is the plastic floor itself distributed, you shop this must be afraid of children playing on the ground fall

- Q:That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- What do you do with the clinker, waterproof? No, I do not recommend when tile put cloth cloth with no clinker clinker, the original ground firmly fixed, after you tile paste, there will be many problems, such as hollowing.

- Q:Is the plastic floor good or the carpet good in the room with the plastic floor or the carpet?

- This problem should be a good carpet, plastic floor is a chemical, how many contain harmful substances harmful to human health

- Q:Plastic floor gap can be used to do plastic glass

- No, glass glue is black and transparent,Plastic floor general welding is another splicing processing, plastic flooring material selection PVC special glue, stairs, wall with adhesive

- Q:My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, formaldehyde removal method of Han purple is physical adsorption by palygorskite and sepiolite based, adding diatomite, tourmaline and other natural minerals, after special processing technology is made, in which the pore pore size between 0.27 - 0.98 nm and a crystal arrangement. At the same time is weak, formaldehyde, ammonia, benzene molecules, toluene and xylene in diameter 0.40.62 nm, and it is a polar molecule, so it has the features of preferential adsorption of formaldehyde, benzene, TVOC and other harmful gases, to purify indoor air effect

- Q:The main features of PVC floor

- PVC, also known as polyvinyl chlorideAdvantages: corrosion resistance! Good tensile strength; compressive strength!Disadvantages: poor ventilation; flexible than other plastics; quality is not good PVC also has a small amount of toxicity; at low temperature is more brittle; smell is relatively large!

- Q:Board PVC plastic floor plastic toxic

- Board PVC plastic floor is a green plastic decoration materials, no poison.

- Q:Home decoration with plastic floor, please? What are its strengths and weaknesses?

- The shortcomings of the plastic floor: the laying of the floor construction requirements will be higher, to consider the floor, environment and other factors, some of the higher technical content

- Q:How much is a normal plastic floor

- The price is about 20 yuan a square meter, such as the sports floor is the main step, mainly to see what occasion you use a slightly different price, hoping to help you

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Durable Click Lock Waterproof And Healthy Wood Texture PVC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords