Ductile Iron Pipe Standard: ISO2531 DN500-DN1000

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

3) we can do third party inspection according to customer's request.

2.Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Internal Lining: Cement, conform to ISO4179

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

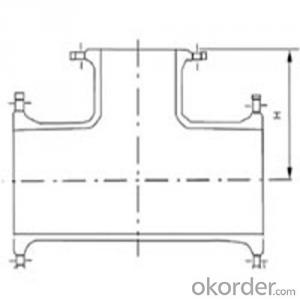

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Standard: API SPEC 5L 44th eidtion,ASTM A252-98(2007)

Grade: A53 Grades A/B, ASTM A106 Grades B/C,ASTM A179

Weld Alternatives: LSAW

OD size range: 6.4~44.5mm

Wall thickness: 406.4~1422mm

Length: 3 - 12 m according to requirment

Note: Other grade can also be provided after consulting. Special design are available for coal slurry conveyance LSAW line tube.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q:will liquid iron stick to water

- Liquid iron is iron. It does not have a different name like we have for ice and water. It is very hot. In water it would cause the water to steam and the iron would go back to a solid. Melting point of iron is 1536oC or 2792oF

- Q:So I am trying to increase my iron levels as I have to give blood soon. Well I picked up an iron supplement and I took one. Well I just realized that it has 65 mg of iron in one pill. Why would they sell these if toxicity is over 50mg. Am I gonna be okay?

- It is great that you are giving blood. However, unless you are suffering from iron deficiency anemia, no amount of iron is going to increase your hemoglobin count. You could take iron after the event, to speed up recovery, but most people do not have a problem in getting back to a normal level. 65mg of elemental iron ( usually in salt of iron about 300mg ) is the treatment dose for simple anemia. Toxic levels for an adult male start at about 700mg of elemental iron daily. If your hemoglobin level is normal, you need no more than 20mg daily for good health. Plenty of foods contain iron including green vegetables and liver

- Q:how hot can an iron get

- i've got been given ceramic braces seek for suggestion out of your community dentist thou cus they diff fees on diff areas. they could stain although if u dont guard them yet no longer as costly as invisilign. goodluck.!

- Q:Are iron supplements taken from animals?

- I do not have remote.how can I turn off alarm

- Q:my iron is sorta low, and they told me liver was a good source of iron but what other types of food have moderate or high amounts of irons

- You should not drive a car 10 feet without transmission fluid, DON'T DRIVE YOUR CAR.

- Q:will i gen iron poisining

- The recommended daily intake of iron is 8mg for men and 18mg per day for women age 19-50. Although 56mg is a bit high, toxic doses usually begin at 20mg per kg of body weight. So, for a 140 lb. person, that would be 2800mg of iron, and that is a conservative value. It would most likely take more than that to be lethal. You will be ok, assuming you do mean 56mg and not 56g!! that would be extremely dangerous.

- Q:Where to getcheap iron sets? also

- Irons that are used for controlled hits like wedgesputterss. etc. need stiffer shafts. Long drive irons need a whip effect to get distance. You can get inexpensive irons (cheap) at golf stores, golf pro shops and prbably on line. These can be either second hand or knock offs on sale. Spartawo.

- Q:Who would win and why?I‘ll say Luke Cage and Iron Fist.

- Captain America and Iron Man. Cap would hold off Iron Fist while Iron Man bombards Luke Cage with all he's got. If a shotgun blast can put him in the hospital, just think of what Iron Man's blasters and missiles could do to him. Captain America would probably end up losing to Iron Fist, but by the end of the fight, Iron Fist would be badly beaten, and Iron Man could easily finish him off.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe Standard: ISO2531 DN500-DN1000

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords