Ductile Iron Pipe ,K9 with High Quality Popular

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile Iron Pipe ,K9 with High Quality

Product Description

CNBM ductile iron pipe ranges from DN80-DN2000mm (Tyton, T-Type, Class K7/K8/K9), effective length: 6m, complying with ISO2531and EN545 standards.

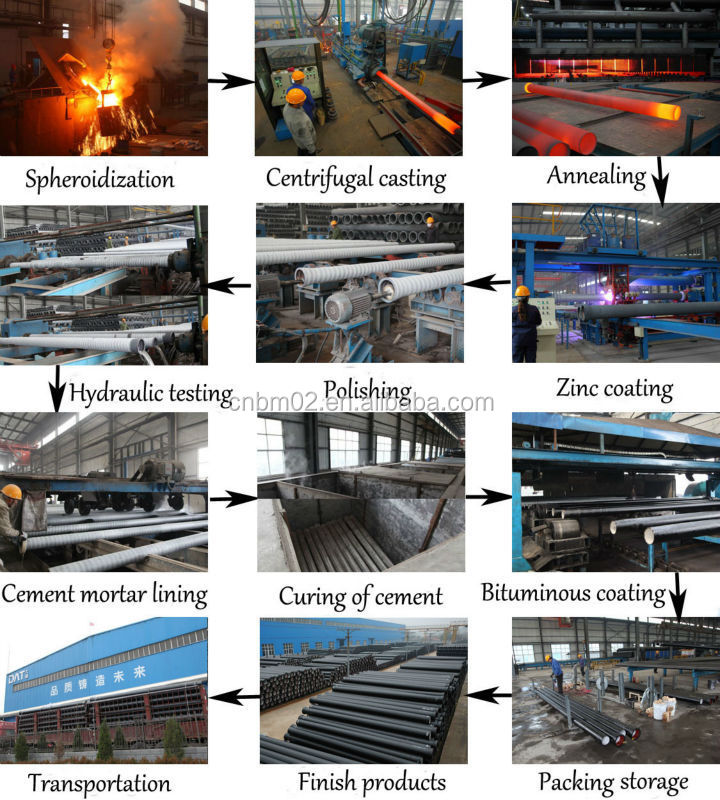

Technical Process

DN80 Ductile Iron Pipe Manufacturer

Specification

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Packaging & Shipping

Packing: in bulk or container.

Our Services

Trustworthy financial strength.

One-stop shopping.

Fast and efficient service.

Coordination of shipments from multiple plants.

Specialists of the overseas shipping process.

A more competitive price.

Company Information

CNBM International Corporation is the leading production base and renowned supplier of Ductile Iron Water Pipe systems of both potable and waste water in China. We are constantly looking to develop high quality products to ensure the longest service life and wonderful performance.

CNBM Pipelines regard quality as the essential factor leading to successful business. Every pipe is tested in accordance with BS EN545 (water application) or BS EN598 (sewer application). CNBM Pipelines products comply with and are tested according to the relevant European and International Standards. Our pipes are manufactured under the quality management system BS EN ISO 9001. After years of efforts, CNBM Pipelines has built up great reputation in terms of quality and service among customers worldwide.

- Q:How are ductile iron pipes joined to fittings and valves?

- Ductile iron pipes are typically joined to fittings and valves through a process known as flanged connection or mechanical joint. Flanged connections involve the use of flanges, which are circular discs with evenly spaced holes around the perimeter. These flanges are bolted together, creating a tight seal between the pipe and the fitting or valve. To join a ductile iron pipe to a fitting or valve using a flanged connection, the pipe end is first prepared by cleaning and deburring any rough edges. A gasket made of rubber or other suitable material is then placed between the pipe end and the flange face. The flange is aligned with the pipe, and bolts are inserted through the holes in the flange, passing through corresponding holes in the fitting or valve. Once all the bolts are in place, they are tightened evenly, gradually applying pressure to compress the gasket and create a secure and leak-proof seal. To ensure proper alignment and sealing, tightening the bolts is typically done in a specific pattern or sequence. Alternatively, ductile iron pipes can also be joined to fittings and valves using mechanical joints. This involves the use of a rubber gasket or gland that is inserted into a groove on the pipe end. The fitting or valve also has a corresponding groove, and when the two are brought together, the gasket is compressed, creating a tight seal. Mechanical joints offer some flexibility, allowing for slight movement or expansion and contraction of the pipe. This can be beneficial in applications where there may be thermal variations or ground movement, reducing the risk of pipe failure. Both flanged connections and mechanical joints are widely used in various industries and applications that require the joining of ductile iron pipes to fittings and valves. The choice of joining method depends on factors such as the specific application, pipe size, pressure requirements, and local codes and regulations.

- Q:Ductile iron gears are generally treated without heat treatment

- Certainly. At the very least, the casting must be annealed and other heat treatment according to the requirement of use

- Q:How to control mortar proportioning in ductile iron pipe cement coating

- The mix ratio of cement coated mortar for ductile iron pipes refers to the weight ratio of various raw materials consisting of ductile iron pipes and cement coated mortars.

- Q:Can ductile iron pipe be used for municipal water supply?

- Yes, ductile iron pipe can be used for municipal water supply. Ductile iron pipe has excellent strength and durability, making it suitable for carrying the high-pressure water supply required for municipal systems. Additionally, its corrosion resistance and long lifespan make it a reliable choice for transporting water in urban areas.

- Q:Can ductile iron pipe be used for bridge crossings?

- Yes, ductile iron pipe can be used for bridge crossings. Ductile iron pipe is known for its strength, durability, and flexibility, making it suitable for various applications, including bridge crossings. Its high tensile strength allows it to withstand heavy loads and vibrations, making it ideal for supporting bridges and handling the weight of traffic. Additionally, ductile iron pipe's flexibility allows it to absorb movements and deformations caused by temperature changes, settling, and other factors, reducing the risk of structural damage and ensuring the longevity of the bridge crossing. Furthermore, ductile iron pipe is resistant to corrosion, making it a reliable choice for bridge crossings where exposure to moisture, chemicals, and other corrosive elements is common. Overall, ductile iron pipe's properties make it a suitable and reliable material for bridge crossings.

- Q:What are the different types of fittings available for ductile iron pipe?

- There are several different types of fittings available for ductile iron pipe. These fittings are designed to connect, redirect, or branch off the pipe in various configurations to suit different plumbing or piping systems. One common type of fitting is the flanged fitting, which features a flange or lip on one end that allows for easy bolted connection to another flanged component. Flanged fittings are commonly used in applications where a tight seal is required, such as in water or sewage systems. Another type of fitting is the mechanical joint fitting, which utilizes a gasket and a set of mechanical bolts to create a secure connection between two pieces of pipe. Mechanical joint fittings are often used in underground water or sewer systems. Push-on fittings are another popular option for ductile iron pipe. These fittings have a rubber gasket that is compressed onto the pipe, creating a watertight seal. Push-on fittings are quick and easy to install, making them ideal for applications where speed and efficiency are important. For situations where a change in direction is required, ductile iron pipe fittings such as elbows or bends are used. These fittings are designed to smoothly change the direction of the pipe without causing any significant flow restrictions. Additionally, there are saddle fittings available for ductile iron pipe. These fittings are used to create a branch connection on an existing pipeline without the need for cutting or welding. Saddle fittings are commonly used in irrigation or fire protection systems. Overall, the different types of fittings available for ductile iron pipe provide a range of options to meet the specific needs of different plumbing or piping systems. Whether it's flanged fittings for a tight seal, mechanical joint fittings for underground applications, push-on fittings for quick installation, or specialized fittings like elbows or saddle fittings, each type serves a specific purpose in the overall plumbing or piping system.

- Q:Can ductile iron pipes be used for industrial applications?

- Yes, ductile iron pipes can be used for industrial applications. Ductile iron is a type of cast iron that has significantly improved mechanical properties, including increased ductility and strength, compared to traditional cast iron. These qualities make ductile iron pipes highly suitable for industrial applications where durability, strength, and resistance to external forces are crucial. Industrial applications often involve high-pressure water or fluid transportation, and ductile iron pipes are designed to withstand such conditions. They have excellent tensile strength, which means they can resist deformation and fractures, making them ideal for handling heavy loads and withstanding significant internal and external pressures. Additionally, ductile iron pipes have excellent corrosion resistance properties, making them highly suitable for industrial applications where exposure to harsh chemicals or corrosive substances is common. Their resistance to corrosion ensures a longer service life and reduces maintenance costs associated with pipe replacement or repairs. Furthermore, ductile iron pipes are known for their versatility and adaptability. They can be easily connected and integrated into existing infrastructure, making them a preferred choice for industrial applications. Their high strength-to-weight ratio allows for easy handling and installation, which is essential in industrial settings. In conclusion, ductile iron pipes are suitable for industrial applications due to their improved mechanical properties, corrosion resistance, and versatility. Their ability to withstand high pressures, resist deformation, and adapt to existing infrastructure make them an excellent choice for various industrial applications.

- Q:Fire water supply network adopts ductile iron pipe, the test pressure should be no more than MPa

- To your selected fire pump highest lift 1.5 times to suppress, generally not more than 1.6MPa, if the use of ductile iron pipe, test pressure according to 2MPa to suppress.

- Q:What is the average weight of ductile iron pipe?

- The average weight of ductile iron pipe can vary depending on its size and thickness. Generally, ductile iron pipe ranges in weight from approximately 3.5 pounds per foot for smaller diameters to over 20 pounds per foot for larger diameters. It is important to note that these weights are approximate averages and can vary slightly based on specific manufacturers and pipe specifications.

- Q:Can ductile iron pipes be used for gas distribution systems?

- Yes, ductile iron pipes can be used for gas distribution systems. Ductile iron pipes are known for their strength and durability, making them suitable for carrying various types of fluids, including natural gas. These pipes have excellent corrosion resistance and can withstand the high pressure and stress typically associated with gas distribution systems. Additionally, ductile iron pipes are cost-effective and have a long lifespan, making them a reliable choice for gas distribution networks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe ,K9 with High Quality Popular

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords