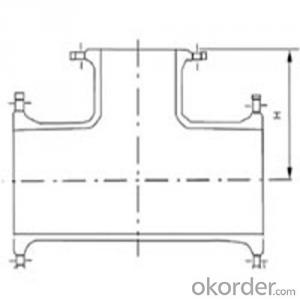

Ductile Iron Pipe Fittings All Flange Tee EN124/d400 DN1200 Grey Iron GG20

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Ductile Iron Pipe Fittings Description :

Our product is an ideal material for connection, which is widely applied to construction machinery, chemical industry and other areas, especially in pipe linking system. It can be widely used under all conditions for a long time.

2.Main Features of the Ductile Iron Pipe Fittings:

1. Best Raw material

2. Good service

3. Competitive price

4. Fast delivery

5. High quality products

Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

• Inspection: inspect in house, all our products must be checked 3 times before packing

Inspection

• In-house Foundry

• Third party inspection available upon requirement

Our goal

• To be your preferred partner

3.Ductile Iron Pipe Fittings Images:

4.Ductile Iron Pipe Fittings Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic ,sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe fittings rather than other pipe fittings materials?

A:The reasons are obvious for that not only ductile iron pipe fittings possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes fittings, improving resistance to erosion of the sewage components.

- Q:is steel stronger than iron?

- It depends on what you want to use it for. On the Moh's scale, steel is somewhere between 4 and 4.5, whereas iron is between 6 and 7. In swords, both iron and steel kinds have appeared, but steel is slightly better than iron due to its strength-to-weight ratio and its flexibility. Keep in mind, steel--unlike iron--is made of different metals to improve its strength. For piping, steel would be better (but not the first choice among other materials to use). David

- Q:Which is your favorite Iron Chef on Food Network?

- chef michibo and the swedish chef

- Q:so yeah how do i corkscrew my hair with my flat iron?:)

- I Don't think you can do that. You should use a Hot comb !

- Q:I was wondering how good the straightening irons work

- They are not good i recommend a Chi or FHI but if you dont want to spend too much money)both are about 150-200$) Jilbere ceramic flat irons are just as good (I have a Chi and a Jilbere and the Jilbere works better) and they are about 50 bucks at Sally Beauty Supply.

- Q:what do i eat for an iron deficiency?

- Peas, Spinach, Liver.

- Q:My niece decided to flat iron her barbie‘s hair and when i came home it was stuck on the iron, how do i get it off ?

- oh my gosh! I would so freak! Try ironing onto a paper sack.like to get wax off. Or maybe onto cotton.something that the hair would come off on.

- Q:I just bought a new set of clubs and in the set were two hybrid clubs. are they better than irons or are the irons a better choice to use?

- I have an 18 and 21 degree hybrid. Tossed out the 2-4 irons and can hit the 18 220 yards and straight as an arrow. It's very forgiving. If you are a 15+ handicapper, these may be just the ticket. I'm not sure what to do with my 3 wood now, however.

- Q:what are iron filings? what characteristics does iron filings have? is it a metal because it is attracted to magnets?

- they are what they say they are. They are the small bits of iron that are 'filed' off a piece of iron using a file. They are very good for showing the magnetic field of a magnet through a piece of paper. Just small bits of iron.

- Q:Is it true that iron was not originally found on the earth and that the iron that‘s present now came from space?Thanks.

- By scientific standards, the formation of iron is one of the most violent processes imaginable. A type of star known as a red giant begins to turn all of its helium into carbon and oxygen atoms. Those atoms then begin to turn into iron atoms, the heaviest type of atom star can produce. When most of a star's atoms become iron atoms, the star becomes what is known as a supernova. It explodes, showering space with iron, oxygen and carbon atoms far and wide. From here, gravity takes over, forming the atoms into planets such as Earth.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe Fittings All Flange Tee EN124/d400 DN1200 Grey Iron GG20

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords