Ductile Iron Manhole Cover of High Quality Made in China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects.

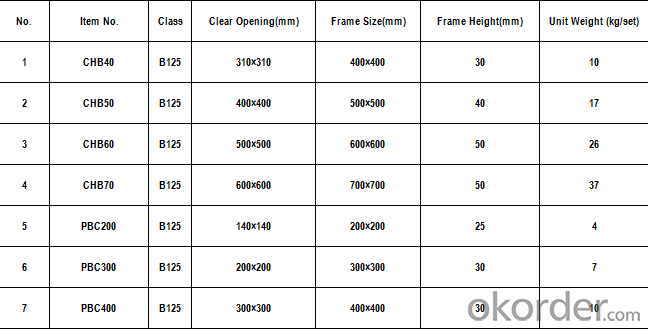

Specifications:

Features:

1.Higher quality /higher tensile

2.Higher security /long life

3.Possibilities of new locking systems

About Our Company:

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

Pictures:

Packaging & Shipping:

1.Packaging: Details Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 30-45 days.

- Q:What is the difference between forging parts and casting parts?

- No, it's called die castingDifference: the die casting parts are simple in structure and large in batch sizeCasting: the use of a wide range of structures without restrictions

- Q:What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q:What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q:What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q:How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q:What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q:What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q:Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q:Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q:After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Manhole Cover of High Quality Made in China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products