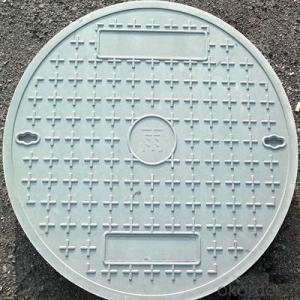

Ductile Iron Manhole Cover of Heavy Duty with EN124 Standard of Square or Round

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or samples.

2) Color: black, Grey, green, blue and Marble , etc.

3) Applications: water supply and drainage, fire engineering, natural

4) Inspection: in-house or the third party as per customer's request.

Advantages:

Good compressive, bending and impact strength,anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal

and no recovery value, anti-theft.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Specification

| No. | Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| 1 | CHB40 | B125 | 310×310 | 400×400 | 30 | 10 |

| 2 | CHB50 | B125 | 400×400 | 500×500 | 48 | 17 |

| 3 | CHB60 | B125 | 500×500 | 600×600 | 50 | 26 |

| 4 | CHB70 | B125 | 600×600 | 700×700 | 50 | 37 |

| 5 | PBC200 | B125 | 140×140 | 200×200 | 25 | 4 |

| 6 | PBC300 | B125 | 200×200 | 300×300 | 30 | 7 |

| 7 | PBC400 | B125 | 300×300 | 400×400 | 30 | 10 |

| 8 | PBC500 | B125 | 400×400 | 500×500 | 33 | 17 |

| 9 | PBC550 | B125 | 450×450 | 550×550 | 33 | 2 |

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

Why imported Composite Manhole cover/Grating from

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building materials you buy from Miami, Dubai ,Italy, South Africa or your local market are imported from China. So why not buy direct from

- Q:Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

- Q:What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The main content of red sand table (Institute of soil science, China) silica 79.4%. three 1.48%. three 10.55%. two aluminum oxide iron oxide, calcium oxide 0.85%. Magnesium Oxide 0.52%. 1440. refractory mud 3.06% LOI 1.98% red sand with high silicon content, permeability is strong, durable, high refractoriness, good angle, low moisture content, less mud the casting finish is high, the basic requirements of sand should meet the following requirements: Casting of high purity and cleanliness, with silica sand as an example, iron sand SiO2 content of more than 90%, the big steel casting requests the SiO2 content of more than 97%; the high refractoriness and thermal stability; the suitable particle the shape and particle composition; it is not easy to be wetted by the liquid metal; cheap. The particle shape and composition of casting sand particle shape and particle composition permeability properties such as mobility, sand compaction, permeability, strength and resistance to liquid metal effects, is an important indicator of the quality of casting sand.

- Q:Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q:ZGMn13 casting parts processing, with what knife head good?

- its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

- Q:What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q:Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q:In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q:We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q:Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

- Q:There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Manhole Cover of Heavy Duty with EN124 Standard of Square or Round

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products