ductile iron manhole cover and drain grating manhole cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 230 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

1.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

2.Designs: based on EN124 standard and according to customer's drawing or samples.

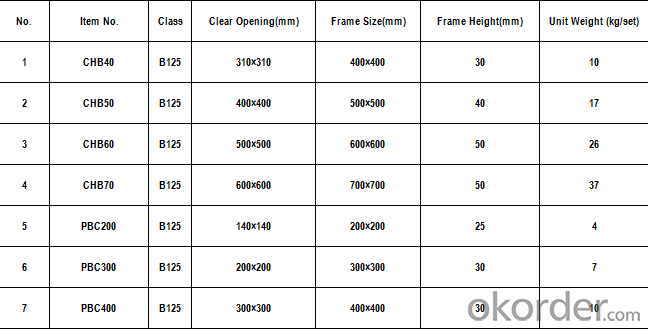

Specifications:

Packaging & Delivery:

1.Packaging Details: Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 8 days if your order is 20"container

Features:

1.Higher quality /higher tensile

2.Higher security /long life

3.Possibilities of new locking systems

4. Good compressive, bending and impact strength,anti-corrosion, not rust, long service life (at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery.

E. Good after sales service.

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air.

B. Less than one container you can choose LCL shipment by sea.

C. One container or more than one container you can choose FCL shipment by sea.

4.Could you specially design and produce for clients?

A: Sure, we have all kinds of professional engineers.We can design and produce special products according to customers' request. Such as: special size, special control, OEM, etc.

5. What’s the MIDAS main market?

A: Our main market is African, Middle East Countries, South American, Asian.

Pictures:

- Q:Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- uch as: automobile transmission shaft adopts mechanical rolling machine with good performance, gray cast iron can play seismic effect effectively, with good thermal conductivity of radiator graphite in gray cast iron, the aircraft engine turbine blade by casting directional solidification casting and Dan Jingzhu.Do everything we can to make the best use of it, the advantages and disadvantages of rolling and casting, and you'll find it yourself, Baidu, depending on how you use it

- Q:What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q:our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Steel parts are not familiar. But after spraying, the powder should be divorced from the adhesive force is too low, try to provide the surface roughness of the casting

- Q:What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q:In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q:What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q:What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q:How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q:When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q:What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ductile iron manhole cover and drain grating manhole cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 230 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords