Ductile iron gate valve ductile iron best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

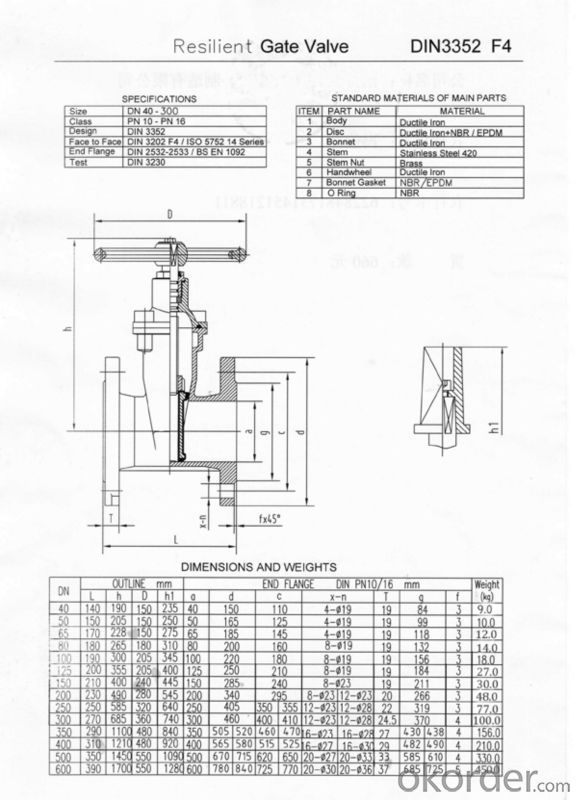

| Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Medium Pressure,PN10/PN16/PN25 |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Normal Temperature |

| Media: | Gas | Port Size: | DN100 | Place of Origin: | Zhejiang China (Mainland) |

| Model Number: | Z45X | Brand Name: | Kejia | materials: | ductile iron |

Packaging & Delivery

| Packaging Detail: | gate valve packed in plywood cast |

| Delivery Detail: | within 30 days after received the first payment |

Specifications

ductile iron valve ,gate valve,air valve

1.High Quality

2.low Price

3.Fast Delivery.

Ductile iron valve ,gate valve

Summarize

As the traditional valve products is easy to leak and rust, our enterprise has introduced advanced technology

and producted resilient sealing gate valve which can overcome the disadvantages including poor sealing

property, elastic fatigue, easy to rust etc. The resilient gate valve is the updating product, it can reach

favourable sealing effect by using of the compensation effect of micro-transformation, this valve can be

widely used in tap water, sewage, construction, food industry, electric power, pharmacy, metallurgy, light textile,energy system and so on.

Advantages

Flat bottom design

The traditional valve can not be tightly closed if there exists sediment in the valve bottom grooves, our seat

sealing valve owns the flat bottom design which is the same as water pipe line, so there will be no sediment and

no leak any more.

Overall packaged with glue

The valve adopts high-quality rubber coating with inside and outside of the valve, using the domestic first-class rubber vulcanization technology to ensure the accurate size of the vulcanized valve disc, the solid

connection of rubber and ductile iron valve disc provide a good elastic memory.

Corrosion resistant

The valve body is coated with epoxy power to prevent corrosion and rusting of the body, and can be used for

the sewage system.

Ductile cast iron material

All the valve body and valve cover are made of ductile cast iron which improve its strength and hardness

greatly.

Three O-ring sealing

The three O-ring sealing washer (as the shaft sealing)greatly reduced the resistance and leaking.

The precision casting body

The body uses the precision casting which can guarantee the sealing of the valve.

Embedded copper nuts

The nuts and resilient valve are combined closely by embedded connection, so the valve may not be loose or

damaged by vibration caused by water flow.

Suitable for drinking

The inside and outside of the valve is electrostatic sprayed with epoxy which can stop the corrosion and rust, so

the valve can be used in both sewage system and drinking water pipe line.

Light weight

The ductile iron reduce the body weight by 20% to 30%, as it’s lighter than traditional gate valve, it’s easier for

installation and maintenance.

- Q:What is the main function of the valve?

- Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q:What's the difference between valves and valves without valves?

- In that regard, some valves are one-way valves, only out of the can

- Q:Where is the Shandong valve? How about joint valves in Shandong?

- Zigong Sichuan power station valve factory is a professional power equipment supporting valve factory, mainly power plant high temperature and high pressure valve, plug valve, ball valve, temperature reduction and pressure relief device

- Q:such as gate valve, three way plug valve

- The lower part of the pressure gauge installed water pipe, there are water, avoid high temperature, medium pressure gauge contact directly cause damage, so regular cleaning, in order to avoid congestion, three way plug function is used for flushing, please see "how to operate them.".

- Q:Ketem valve relative to other valve companies in the industry what are the advantages?

- Floating seal: electric drive, electric ball valve flange connection floating ball straight, seal form with seal, the sealing surface of the valve seat material for hard alloy, nominal pressure PN16~PN63, nominal size DN15~DN200, suitable temperature of -28~500, the valve body is made of carbon steel or stainless steel. As a result of the use of hard sealing (metal seal), this valve is particularly suitable for particles, solids, slurry and other medium and high temperature and high pressure pipelines.

- Q:Excuse me American Standard pressure test valve GB standards are much ~ is how much valve pressure can play much pressure? Thank you

- The standard is different, the test is not the same, what kind of valve you, a domestic valve only do stress testing, in fact, the pressure can generally be guaranteed, many are bad at high temperature or life testing above

- Q:What kind of valves are best used for sand drain valves?

- Suzhou ATW Valve Co. Ltd production of sealing ball valve, Suzhou ATW Valve Co., according to the condition of solid particles, long-term research and in practice, and achieved good results in the condition of solid particles. You can try!

- Q:What's the name of the valve?

- This is the discharge valve, the lower part of the handle protruding part of the valve is the sealing device. The overall material should be brass, which is typically made by equipment manufacturers.

- Q:How to identify the good or bad of the valve, without pressure test and instrument?

- First, the appearance, two according to the standard to see flange thickness, outer circle, wall thickness and other dimensions are standard, 3 see details.

- Q:How to better maintain the valve?

- How to maintain the valve?Enter the same as other mechanical products, but also the need for maintenance. This work well, can extend the service life of the valve, the following will introduce the valve maintenanceStorage and maintenanceThe maintenance of the purpose is to keep the valve in the custody of the damage, or lower quality. In fact, improper storage is one of the important reasons for valve damageThe valve custody, should be arranged in good order, a small valve on the shelves, large valves can be neatly arranged in the warehouse on the ground, not arbitrary lumber pile, do not let the flange face contact with the ground. This is not only for beauty, mainly to protect the valve, not to touch badBecause the storage and handling properly, hand wheel broken, crooked stem touch the fixed nut hand wheel and stem loosening loss and so on, these should avoid unnecessary losses.We temporarily on the short-term use of the valve, should remove the asbestos packing, in order to avoid electrochemical corrosion damage to the valve stem.I just entered the library on the valve, to conduct inspections, such as during transport into the water or dirt to wipe clean, re storedThe import and export of valves to use wax paper or plastic sheet sealed to prevent dirt insideThe valves on the machined surface rust in the atmosphere should be coated with anti rust oil, protectI placed outside the valve, must be covered with linoleum or tarpaulins like rain, dust items. Keep the storage of the valve clean and dry

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile iron gate valve ductile iron best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords