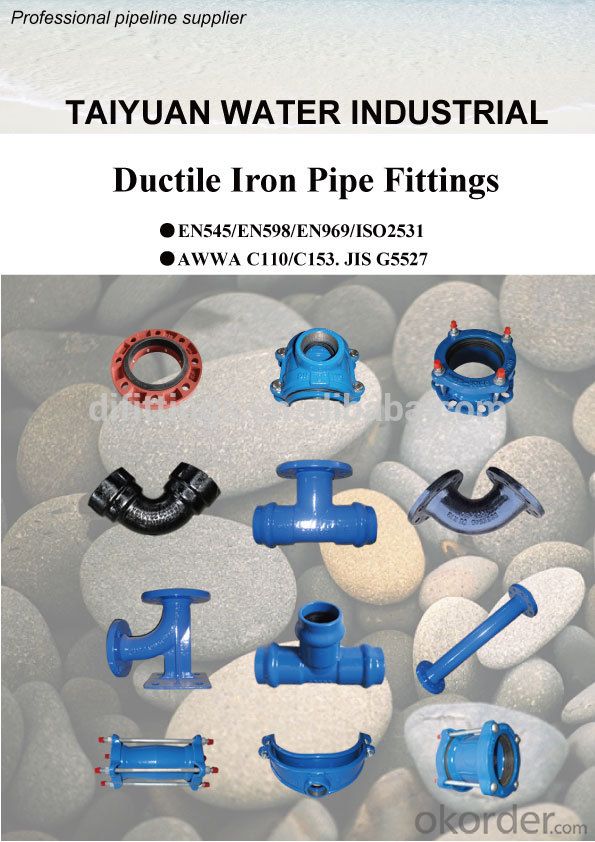

Ductile Iron fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

China ductile cast iron fittings bend/elbow with flange

Standard:EN545/ISO2531/NBR7675

PN10/PN16/PN25

FBEP/BITUMEN COATING

TAWIL EN545/ISO2531 China ductile cast iron fittings bend/elbow with flange :

Material:ductile iron Pipe Fitting;

Type: All sockets tee or All flange tee or double flange with flange branch tee;

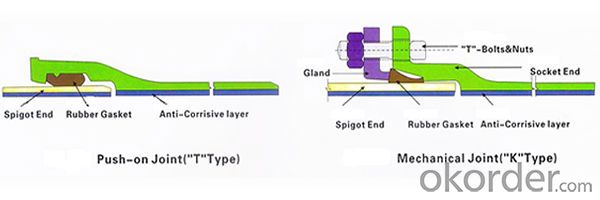

Joint structure: Socket or Flange or mechanical joint or Push-on Joint ;

EN545/ISO2531/NBR7675 ductile iron pipe tee fittings product data:

• Joint structure >>>

• Mechanical Properties >>>

Centrifugal Cast Pipes | Fittings | ||

DN80toDN1000 | DN1100toDN2600 | ||

Tensile Strength | Min.420N/mm2 | Min.420N/mm2 | |

Elongation | Min.10% | Min.7% | Min.5% |

Proof Stress | Min.30N/mm2 | Min.300N/mm2 | |

Hardness | Max.230HB | Max.250HB | |

The proof stress shall be measured only upon special agreement and under conditions which shall be specified in the order.

• Deviation and tolerances on length>>>

The permissible deviation on the standard working length of fittings with sockets and fittings with flanges are given in table as follows:

Type of fitting | Length | Deviation(mm) |

Flanged socket | L | DN80 to DN1200 ± 25 DN1400 to DN2000 ± 35 |

Flanged spigot | ||

Collar | ||

Taper | ||

Bend90° | t | ±(15+0.03DN) |

Bend45° | t | ±(10+0.025DN) |

Bend22.5°and11.25° | t | DN80toDN1000±(10+0.02DN) DN1200toDN2000±(10+0.025DN) |

Tee | L and h | DN80toDN1200-25+50 DN1400todn2000-35+75 |

• Tolerances on manufacturing working lengths>>>

The standard tolerance on the manufacturing working lengths of all fittings with flanges in all nominal size is ±10mm On request in the order and by agreement between the manufacturer and the purchaser,smaller tolerances can be accepted but not less than: ±3mm for DN≤600and±4mm for DN≥700

• Works leak-tightness test>>>

The fitting shall be submitted at the works to a leak-tightness test,carried out either with air at a pressure of 1 par or with water at the pressure given in table as following:

Nominal size DN | Hydrostatic leck-tightness test pressure bar | |||||

Fittings | DI Pipe with weld-on or screwed-on flange | |||||

PN10 | PN16 | PN25 | PN40 | |||

80≤DN≤300 | 25 | 16 | 25 | 32 | 40 | |

350≤DN≤600 | 16 | |||||

700≤DN≤2000 | 10 | |||||

• Internal protection>>>

Spun the blast furnace cement mortar lining complying with the standard ISO4179, or we may offer special protective coating according to customers requirements.

• External Protection>>>

Metallic zinc complying with the standard ISO8179,and bitumen,or we may offer special protective coating according to the customer's requirements.

• Ductile iron pipe fittings-----BEND>>>

- Q:It‘s a personal opinion people so no one go off on a rant pleas!! I personally like Iron Maiden more. But I will admit Idk if I‘d think that w/o Bruce Dickinson. Iron Maiden is still great no matter who‘s singing but I don‘t really think the other singer‘s voice flowed as well. which band do you think has a better guitarist?

- Iron Maiden! m/ Not that Metallica is a slouch, by any means, but Iron Maiden is much more consistent, and are actually still good today!

- Q:What is chelated iron and how does it differ from the regular iron pills at the supermarket? Is it safe for anyone to take? I noticed the chelated iron is only sold at the health food store. Is chelated iron safe for someone with a very sensitive digestive system to take?

- Chelation is the pharmaceutical process of bonding a mineral to an amino acid to make it easier for the body to digest, assimilate and utilize it. Chelated minerals, or chelates for short, are designed to mimic the way minerals occur naturally in the diet as well. Chelated iron, while not as widely known as iron sulfate, is ten to fifteen times more bioavailable per mg than other types of dietary iron supplements.

- Q:My iron has settings 1-9 which one would be the polyester setting?

- My iron has 6 settings and #3 is for rayon and polyester. You have to be careful that it isn't too hot because you can put a wrinkle in polyester or even melt it. You might try out the temp somewhere it won't show-a facing maybe.

- Q:What are some foods rich in iron for 11 months old baby?IS carrot and brocolli good for iron?

- My mother-in-law always used to swear by seafood chowder being rich in iron. Now I don't know if you want to give it to two small children. Broccoli is high in iron .I think beans are as well. Not sure about carrots. I know they have some, but not sure how much. You could try some more exotic food such as egg plant, turnip, leeks. Things along that nature. Good Luck too you and happy hunting!!!!!!!!!! You never know what you will find that you and your family can enjoy together. Who know's, you may even start a life long passion!!!!!!!!!!!

- Q:I am working on a chemistry problem, and I have no clue what the formula is for molten iron, is it just iron aqueous? Thank you!

- This Site Might Help You. RE: What is the formula for molten iron? I am working on a chemistry problem, and I have no clue what the formula is for molten iron, is it just iron aqueous? Thank you!

- Q:what are iron filings? what characteristics does iron filings have? is it a metal because it is attracted to magnets?

- they are what they say they are. They are the small bits of iron that are 'filed' off a piece of iron using a file. They are very good for showing the magnetic field of a magnet through a piece of paper. Just small bits of iron.

- Q:I do not like ironing clothes. I was wondering if the cleaners in US also provide ironing services without the cleaning/drycleaning services.

- my mum hadnt done it for a good few weeks and there was like 4 heaped baskets so she thought why not so we went to a place called the iron-inn and they dry cleaned too. they pressed them all and put them all on hangers (even teeshirts) and in bags lol. but the price was per item which was a shocking 200+ dollars. whoa. look at ads on the newspaper people will take in a basket for so many dollars. launderettes sometimes do it too maybe a deal like 2 baskets for the price of one or something

- Q:anymore? what are most of the iron products?

- Most iron is converted to steel. Iron is usually too britttle and less consistent (less homogeneous) than steel for use in most applications. The other common uses of iron are cast iron for engine blocks and ductile iron for water and sewer piping. It is less prone to rusting than steel when installed in the ground although protective coatings will extend the useful life. Iron is also used in other industrial applications which would not be familiar to most consumers- pump volutes and blower housings. Iron is not used for wire because iron wire would not be bendable or shapeable. It is brittle and would most likely break during the installation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords