Ductile Iron Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

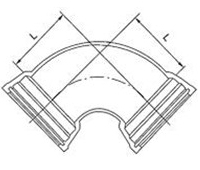

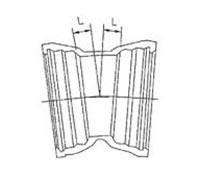

90° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 100 | 8.6 | 12.0 |

100 | 120 | 11.5 | 15.6 |

150 | 170 | 20.5 | 27.5 |

200 | 220 | 33 | 40.0 |

250 | 270 | 48.5 | 55.5 |

300 | 320 | 68 | 81.5 |

350 | 370 | 83 | 105 |

400 | 420 | 143 | 134 |

450 | 470 | 156 | 166 |

500 | 520 | 183 | 202 |

600 | 620 | 273 | 290 |

700 | 720 | 455 | 408 |

800 | 820 | 605 | 544 |

900 | 920 | 813 | 720 |

1000 | 1020 | 1045 | 935 |

1200 | 1220 | 1508 | 1444 |

1400 | 1220 | 2419 | 1918 |

1600 | 1290 | 3382 | 2543 |

1800 | 1320 | 3616 | 3229 |

2000 | 1360 | 4516 | 4033 |

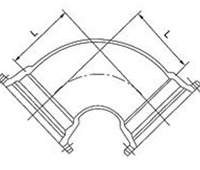

45° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 55 | 7.7 | 11.1 |

100 | 65 | 10.1 | 14.3 |

150 | 85 | 17.5 | 24.0 |

200 | 110 | 27 | 34.0 |

250 | 130 | 38.5 | 45.5 |

300 | 150 | 53 | 66.0 |

350 | 175 | 70 | 83.5 |

400 | 195 | 89 | 104 |

450 | 220 | 117 | 124 |

500 | 240 | 139 | 150 |

600 | 285 | 202 | 209 |

700 | 330 | 282 | 289 |

800 | 370 | 378 | 373 |

900 | 415 | 496 | 488 |

1000 | 460 | 635 | 628 |

1200 | 550 | 986 | 943 |

1400 | 515 | 1273 | 1223 |

1600 | 565 | 1740 | 1647 |

1800 | 610 | 2296 | 2166 |

2000 | 660 | 2970 | 2791 |

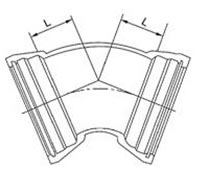

22.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 40 | 7.5 | 10.7 |

100 | 40 | 9.5 | 13.5 |

150 | 55 | 15.9 | 22.5 |

200 | 65 | 24 | 30.5 |

250 | 75 | 33.5 | 40.5 |

300 | 85 | 44.5 | 58.0 |

350 | 95 | 58 | 71.0 |

400 | 110 | 74 | 88.0 |

450 | 120 | 95.0 | 105 |

500 | 130 | 111 | 123 |

600 | 150 | 157 | 164 |

700 | 175 | 217 | 223 |

800 | 195 | 287 | 281 |

900 | 220 | 373 | 364 |

1000 | 240 | 470 | 463 |

1200 | 285 | 716 | 671 |

1400 | 260 | 933 | 882 |

1600 | 280 | 1259 | 1167 |

1800 | 305 | 1663 | 1533 |

2000 | 330 | 2114 | 1965 |

11.25° Double Socket Bend

K12

Available in T Type and K Type;

Size: DN80-2000

Angle: 11.25, 22.5, 45, 90 DEG

We are involved in the manufacture and supply of the ductile iron Double Socket Bend. We manufacture these with the premium quality raw materials. Our Double Socket Bends ensure high durability and strength. Our range of Double Socket Bends caters to various industrial requirements. We offer these Double Socket Bend in different sizes and lengths in order to meet the various requirements of our esteemed clients.

Nominal Diameter DN | L | Mass(kg) | |

T Type | K Type | ||

80 | 30 | 7.1 | 10.5 |

100 | 30 | 8.9 | 13.1 |

150 | 35 | 14.8 | 21.5 |

200 | 40 | 22 | 29.0 |

250 | 50 | 30.5 | 37.5 |

300 | 55 | 40.5 | 54.0 |

350 | 60 | 52 | 65.5 |

400 | 65 | 65 | 79.0 |

450 | 70 | 83.5 | 93.5 |

500 | 75 | 96 | 108 |

600 | 85 | 134 | 141 |

700 | 95 | 181 | 187 |

800 | 110 | 239 | 234 |

900 | 120 | 305 | 297 |

1000 | 130 | 381 | 375 |

1200 | 150 | 568 | 524 |

1400 | 130 | 747 | 697 |

1600 | 140 | 1007 | 914 |

1800 | 155 | 1331 | 1200 |

2000 | 165 | 1702 | 1522 |

Packaging & Delivery of Ductile Iron Bend

Packaging Detail: | wooden cases with plastic layer , wooden pallets with plastic layer , steel strip. |

Delivery Detail: | 30days after the order confirmed. |

Specifications of Ductile Iron Bend

MATERIAL:Ductile iron grade 500-7/ 450-10 in accordance with ISO 1083.

STANDARD: ISO 2531/EN 545/EN598

FLANGE: PN10, PN16 or PN25 drilling in accordance with ISO 7005-2/EN 1092-2.

COATING:

a. Zinc coating +bitumen painting;

b. Liquid epoxy painting;

c. Epoxy applied by FBE;

d. Other coating as your requirement

Test:Dimensions and testing in accordance with ISO 2531/EN 545 and 100% water pressure test.

Note: The gaskets, bolts & nuts are supplied respectively as your special requirement.

Usage:

It is a connection is commonly used in pipe installation with fitting, connect two of the same or different nominal diameter pipes.

- Q:Is the pipe seat a pipe joint or a standard connection?

- The branch pipe seat for reinforcing pipe type pipe connection, instead of the traditional use of different diameter three, reinforcing plate, strengthening pipe etc. branch connection type, which has the advantages of safety, lower cost, simple construction, improve the media channel, series of standardization, has the advantages of convenient use,

- Q:What are the reducing, reducing, reducing, etc in the pipe joint?. How do they tell each other what they call that?. Seek expert advice

- The pipe joint is divided into cylindrical pipe thread and tapered pipe thread, and the change of diameter refers to the different diameters of the two ends of the pipe joint

- Q:would you think that person was dumb?i got fired today and i dont understand whyi started in june and at first it was hard, i worked at the back making all the burgurs, so it took a while to learn what goes in eachbut i felt i was getting better everytime i went thereand its not like i stole anything, or came late to my shifts, i was there on time everyime i had a shiftdo you think its because i wasnt good at communicating? i stuter a lot and talking to new people is hard, but like i said, i was getting better everytime i came

- Two solutions: - use dielectric unions between the galvanized iron pipe and the stainless steel hoses, - use a 6 (or longer) hard brass pipe nipple between the galv iron pipe and SS hoses.

- Q:When I was a youngin' in school, they told us that if you pulled the fire alarm, you were sprayed with some kind of ink so they know who pulled it. Is this true, and if it is, isn't it a bit of a hazard in the event of a real fire?

- the maximum fire which takes place is eighter an oven fire or fire in a lavatory or fire while landing 1}. to fight an oven fire we have BCF which is a halon extinguisher, so the crew can easily fight fire 2}. if thre is a fire in a lavatory {toilet fire} that is only coz of the lay out stupid passengers who smoke in the toilet, fire can tak place in the bin or anywhere in the lavatory, so to fight this fire there is an automatic fire estinguisher which is located beneath the sink area if da temp exceeds 77c or 170 f the bcf starts automatically releasing non toxic gasses. 3}.n if there is a fire while landing passengers has 90 secs for ditching out of an air craft. they are provided with oxygen bottle. so dont worry fire takes place in very rare cases, n we cannot provide fire blankets to each passenger when there is only 90 secs for ditching.

- Q:This only happens at night, if we have the air conditoner on, after a few hours, our smoke alarm will start beeping in five minute intervals. We have four of them in the apartment and only one of them beeps. What could be causing this?

- my parents had the same thing in thier old house water pipe coming from thier WELL. It didn't affect the water taste and no one got sick, but if you have concerns,send a sample to your state water testing facility

- Q:How can we extinguish fire causes by petrol?

- As long as he's using real exhaust pipe and real exhaust fittings and clamps, it should work. Probably more work than just buying the whole pipe. But if he wants to work that hard to save $40, have at it.

- Q:I mean each MM is different shape, size and color. How do they individually print the letter M on each one without getting multiple m stamps on each one? Does each one stop in a little chute that stops them from moving then stamps the M, then drops it to continue on its journey to my stomach? I don't know. Skittles are shaped to match all other skittles, and so are the regular mm's. But the peanut MM's, thats a boggle to the mind.

- There are Hubless fittings and parts for this that you may obtain from your local plumbing supply house - including slip fittings to make up unusual lengths. Rent a chain cutter to make nice square cuts and take it from there. Your supply house will cut you a new piece to-size if necessary and give you the exact fittings you need if you bring them a dimension and a piece of the old pipe. With the right tools and patience, this is no more than a couple of hours work on a bad day. Less than an hour on a good one. Do it right and DON'T try to weld it. That will cause almost immediate failure of the pipe around the weld due to compositional change from the heat.

- Q:when shaving down there, how to avoid bumps?

- I frequently tip them. i do no longer think of it they could desire to stand there like morons in the event that they are not tipped regardless of the incontrovertible fact that. it may possibly be an advantage, no longer an expectationdistinctly if a toddler is accepting the transport! that should make me no longer desire to tip them!! i do no longer think of you owe them a proof. i could purely say bye and close the door. Tipping is permitted, yet no longer required. (As a sidenote, i'm presently residing in South Korea, the place tipping isn't cultural it is great! it is not predicted, neither is it ordinary. If I tipped a transport boy, he'd seem at me like i grew to become into loopy, and spout off that I already paid for the nutrition!!)

- Q:If there was a fire and I went to pull the fire alarm what if I read the directions out loud to help me to understand what to do and to make me more confident? Also what if my hand slipped and I had to pull the handle again and I said uh-oh? Do people ever talk out loud to themselves or to a friend standing nearby in this situation? Why is it that someone would do this silently while another one would talk out loud and still get the job done? If a kid were to pull a fire alarm in a fire would they be more likely to talk out loud since it is a new thing for them? What would they say out loud to themselves in this situation to help them?

- We're a single star system. How do we know? Through the usage of telescopes with detectors that monitor very tiny changes in infrared energy (more commonly known as heat). Everything gives off heat. The cosmic background radiation is just above absolute zero and we can detect changes in it to within a millionth of a degree. so if there is a dead star floating around out there, we would know about it. Also, any thing that massive would disrupt planetary orbits. And have been able to detect changes in orbital patterns since the 18th century (read up on how Neptune was discovered).

- Q:What type of motorcycle gloves are these or where can i find some like them?

- Are you serious? Shooting it is the best advice you're going to get. No one can explain to you how to pick a lock via text over Yahoo Answers and no one shouldsoshoot it.

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Bend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 50,000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords