Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

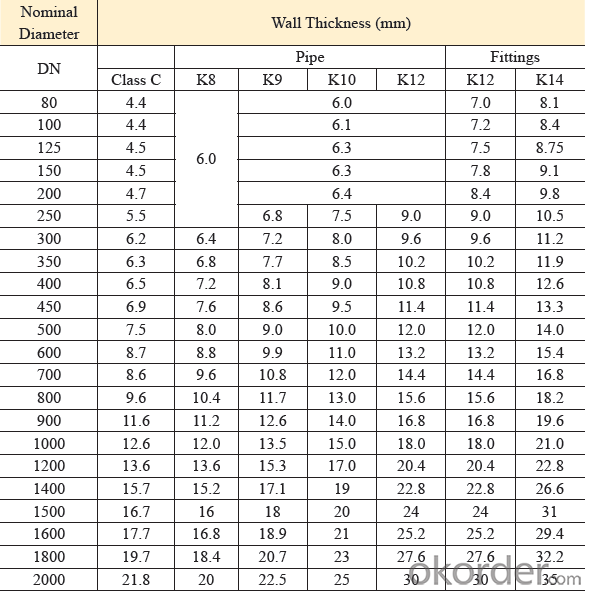

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

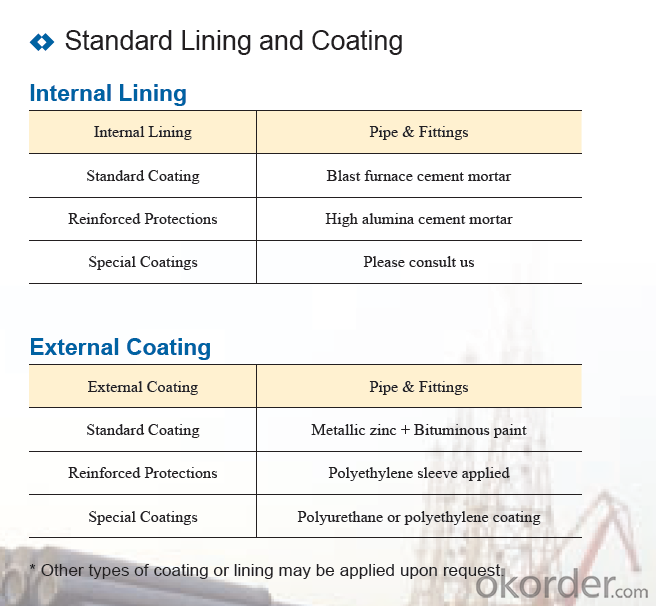

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

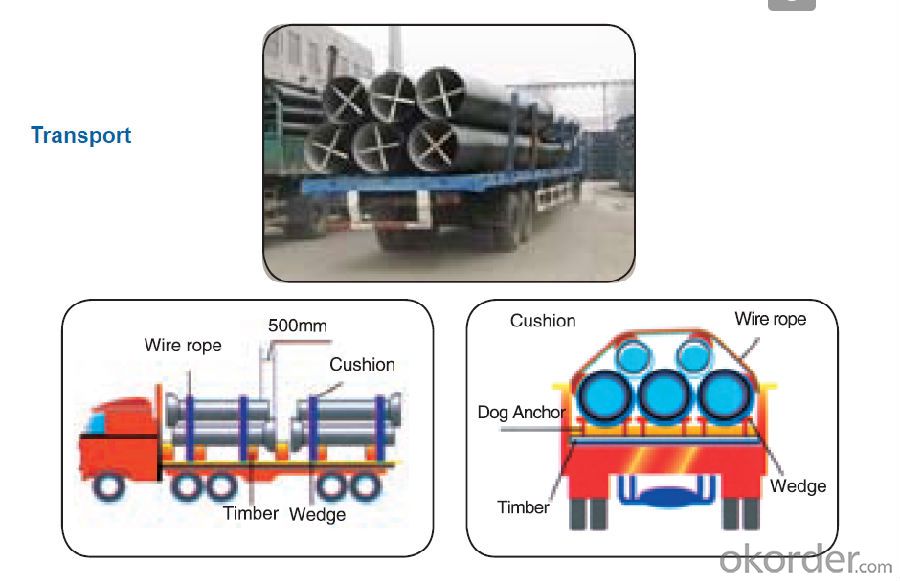

Transport:

- Q:What are the typical joint sealing requirements for ductile iron pipes?

- When sealing joints in ductile iron pipes, two common methods are typically used: rubber gaskets and mechanical joints. Rubber gaskets are frequently chosen for their reliability and flexibility. They are typically made of synthetic rubber materials that are resistant to water, chemicals, and other environmental factors. On the other hand, mechanical joints are also commonly used for sealing joints in ductile iron pipes. These joints utilize a mechanical device to connect the pipes and create a watertight seal. They are designed to allow for some movement and flexibility, which is particularly important in areas prone to ground movement or settlement. In addition to using rubber gaskets or mechanical joints, it is crucial to properly clean and prepare the pipe surfaces before joining them. This involves removing any dirt, debris, or old joint material from the pipe ends to ensure a secure seal. Following the manufacturer's instructions, the joint should be assembled, ensuring that the gasket or mechanical joint is correctly positioned and tightened to the recommended torque. In summary, the typical requirements for sealing joints in ductile iron pipes involve the use of rubber gaskets or mechanical joints, thorough cleaning and preparation of the pipe ends, and adherence to the manufacturer's assembly instructions. These requirements are essential to achieve a durable and watertight joint that can withstand the pressures and environmental conditions commonly encountered in ductile iron pipe systems.

- Q:What are the disadvantages of using ductile iron pipes?

- One disadvantage of using ductile iron pipes is their susceptibility to corrosion. Over time, exposure to moisture and various chemicals can cause the pipes to deteriorate and develop leaks. Another disadvantage is their relatively high cost compared to other pipe materials, such as PVC or HDPE. Additionally, ductile iron pipes are heavy and require specialized equipment for installation, which can increase labor and transportation costs.

- Q:What is the expected joint performance of ductile iron pipes?

- Ductile iron pipes are widely recognized for their outstanding joint performance. They possess exceptional durability and strength, making them suitable for a wide range of applications, including water distribution, sewer systems, and industrial pipelines. One crucial aspect of joint performance in ductile iron pipes is their ability to withstand external loads and pressure. To ensure minimal leakage and long-term structural integrity, the joints in these pipes are designed to create a tight and secure connection. This is accomplished through the utilization of various joint types, such as push-on joints, mechanical joints, and restrained joints. Push-on joints are commonly employed in ductile iron pipes due to their ease of installation. They do not require any specialized tools or equipment. These joints rely on a rubber gasket, which guarantees a watertight seal and prevents leakage. On the other hand, mechanical joints involve the use of mechanical devices, such as bolts and nuts, to establish a rigid connection between the pipes. This type of joint provides additional strength and resistance against external forces. Ductile iron pipes have undergone extensive testing to ensure their performance meets or exceeds industry standards for pressure and bending strength. They exhibit high resistance to corrosion, resulting in a longer service life. Additionally, they are less susceptible to damage caused by ground movements or vibrations. These properties contribute to the overall joint performance of ductile iron pipes, ensuring reliable and efficient operation in various infrastructure systems. When properly installed and maintained, ductile iron pipes display remarkable joint performance. They provide a reliable and durable solution for numerous applications within the water and wastewater industry.

- Q:Are ductile iron pipes suitable for use in brewery facilities?

- Yes, ductile iron pipes are suitable for use in brewery facilities. Ductile iron pipes are durable, corrosion-resistant, and can withstand high-pressure applications, making them ideal for transporting water, steam, and other fluids within brewery facilities. Additionally, the smooth interior surface of ductile iron pipes minimizes friction and prevents the build-up of sediments or organic materials, ensuring the purity and quality of the beer being produced.

- Q:Can ductile iron pipes be used for water supply in remote areas?

- Yes, ductile iron pipes can be used for water supply in remote areas. Ductile iron pipes are known for their strength, durability, and versatility, making them suitable for various applications, including water supply systems. These pipes have a high resistance to corrosion and can withstand harsh environmental conditions, making them ideal for remote areas where the availability of maintenance and repair services may be limited. Additionally, ductile iron pipes have a longer lifespan compared to other materials, ensuring the longevity of the water supply system in remote areas. Overall, ductile iron pipes are a reliable choice for water supply in remote areas due to their durability, corrosion resistance, and long lifespan.

- Q:How does ductile iron pipe perform in areas with high soil contamination?

- Due to its inherent strength, durability, and corrosion resistance properties, ductile iron pipe is highly effective in areas with high soil contamination. The material used in manufacturing these pipes is highly resistant to chemical attack, making it suitable for handling various types of contaminated soils, including those with high levels of acids, alkalis, and other corrosive substances. The corrosion resistance of ductile iron pipes is primarily due to their protective internal and external linings. These linings are designed to prevent contact between the pipe material and the surrounding soil or fluids, acting as a barrier that prevents the penetration of corrosive elements and reduces the risk of pipe degradation or failure. Additionally, external coatings or cathodic protection systems can further enhance the resistance of ductile iron pipes to soil contamination, extending their service life. Compared to materials such as steel or concrete, ductile iron pipes offer significant advantages in areas with high soil contamination. Their high strength enables them to withstand external loads imposed by the contaminated soil, reducing the risk of structural failure or deformation. Furthermore, the inherent flexibility of ductile iron allows it to absorb ground movements or settlement without compromising its integrity, making it a reliable choice for areas prone to soil instability or shifting. Moreover, the smooth internal surface of ductile iron pipes minimizes friction and maintains efficient flow rates, even in the presence of contaminants. This is particularly important in areas with high soil contamination, where debris or sedimentation can accumulate and hinder fluid flow. The smooth bore of ductile iron pipes reduces the risk of clogging and ensures the continuous and reliable conveyance of fluids, even in challenging soil conditions. In conclusion, ductile iron pipe is an excellent choice for areas with high soil contamination. Its exceptional corrosion resistance, strength, flexibility, and smooth internal surface make it a reliable and durable solution for conveying fluids in these challenging environments.

- Q:What is the wall thickness of K10 grade dn=400 ductile iron pipe?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc.. Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external pressure bearing better tightness and corrosion resistance; from the point of view, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q:Do ductile iron pipes have inner enamel?

- Internal enamel ductile iron pipe is yes, but now there is almost no market (except for special process requirements), in the civil construction market, new materials, new technologies, new technologies can be replaced, there are many.

- Q:Can ductile iron pipes be used for stormwater management systems?

- Yes, ductile iron pipes can be used for stormwater management systems. Ductile iron pipes are known for their strength and durability, making them suitable for various applications including stormwater management. These pipes are resistant to corrosion and can withstand high pressure, making them ideal for carrying stormwater runoff. Additionally, ductile iron pipes have a long lifespan, reducing the need for frequent replacements and maintenance. Overall, ductile iron pipes are a reliable choice for stormwater management systems.

- Q:What is the expected bedding and backfill requirements for ductile iron pipes?

- To ensure the longevity and proper functioning of ductile iron pipes, it is crucial to meet the expected bedding and backfill requirements. Although these pipes are known for their durability and strength, careful installation is still necessary to prevent any potential damage or compromised performance. The bedding requirements for ductile iron pipes entail establishing a stable and uniform support system to distribute the loads and stresses from the surrounding soil. The pipe should be surrounded by a bedding material that is devoid of rocks, debris, or any sharp objects that could potentially cause harm. Moreover, the bedding material should be adequately compacted to prevent settlement or shifting, which could result in misalignment or pipe failure. Typically, a granular material such as sand or fine aggregate is employed as the bedding material for ductile iron pipes, with a minimum thickness of 6 inches. This material should be evenly placed beneath and around the pipe to provide a continuous support system. Additionally, it should be compacted to at least 90% of the maximum dry density to ensure proper stability and load distribution. As for the backfill requirements, they pertain to the material used to fill the remaining space around the pipe after the bedding has been installed. Similar to the bedding material, the backfill material should be free from rocks, debris, or sharp objects to prevent damage. It should offer support and protection to the pipe while allowing for proper compaction and settling. The backfill material for ductile iron pipes typically consists of a granular substance such as sand or fine aggregate, with a maximum particle size of 1 inch. It should be placed and compacted in layers, ensuring that the compaction is uniform and even around the pipe. Sufficient compaction is crucial to avoid settlement or shifting of the backfill material, which could potentially harm or misalign the pipe. In conclusion, meeting the expected bedding and backfill requirements for ductile iron pipes necessitates the use of a granular material that is free from rocks, debris, or sharp objects. This material should be evenly placed and compacted to provide stable support and protection to the pipe. Adhering to these requirements will help ensure the proper functioning and longevity of ductile iron pipe systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 40

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords