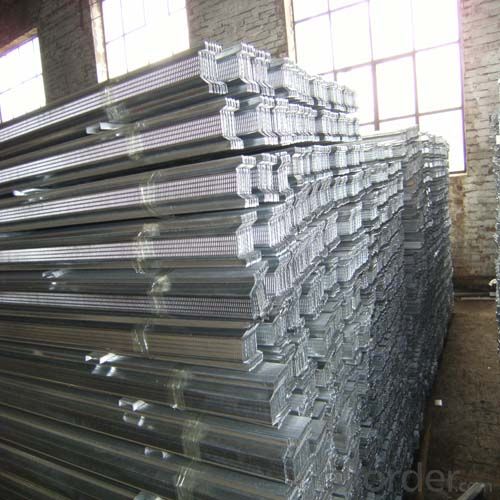

Drywall System Stud Metal Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

1. Raw material of partition light steel keel is high-quality hot dipped zinc galvanized steel strip, which is absolute damp proof , heat-insulating, highly durable , and highly rust resisting.

2. Hot dipped zinc galvanized steel strip zinc coating is 80-160g/m2.

3.Warm sales in Southeast Asia,Middle East , Africa , Oceania , Eastern Europe ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can guarantee accurate size, high-quality products.

Products data:

Component name | Descrption(mm) | Thickness(mm) | Length(mm) | Remark |

Main Channel | 38*10 | 0.45,0.50,0.60,0.70,0 .80,1.0 | 3000 | We can manufacture products on customers' specific requirement. |

38*12 | 0.50,0.6,0.7,0.8,1.0 | 3000 | ||

Furring Channel | 35*22 | 0.40,0.50,0.60 | 3000 | |

35*24 | 0.40,0.45,0.50,0.60 | 3000 | ||

Card Light Steel Keel | 19*25 | 0.6 | 3000 | |

19*28 | 0.8 | 3000 | ||

19*32 | 0.9 | 3000 | ||

19*38 | 1.0 | 3000 | ||

Stud | 40*34.5 50*34.5 70*34.5 75*34.5 100*35*32 | 0.40, 0.45, 0.50, 0.60, 0.70, 0.80 | 3000, 3200 | |

Track | 42*25 52*25 72*25 75*25 100*25 | 0.40, 0.45, 0.50, 0.60, 0.70, 0.80 | 3000, 3200 |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q:6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q:Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q:Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- Sure to press the double calculation, not to mention fixed nine plywood than gypsum board but also a little trouble. The specific price per square is not good to say, there are differences in the price of different regions. I received a company two months ago, a small project, to my wall cost of labor, single and double back, 30 a square. Local minimum wall monolithic gypsum board partition 15 yuan per square, high in 20 or so. A layer of nine percent a layer of gypsum board, the minimum also 30 a square.

- Q:100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- The following is the decomposition of the material (no loss), vertical wall keel spacing is generally @ 400, vertical keel is 2.5m / m2; along the top edge (heaven and earth) keel is 2/3 = 0.67m / m2; Piercing board is 4m2 / m2 partition wall area; large white putty is about 2.5kg / m2 partition wall area, latex paint is 0.5kg / m2 partition wall area. Brush twice to consider; the rest Is the card pieces, nails, bandages, white latex, high-strength nails and oblique support cable-stayed material (wood can be) and other auxiliary materials Usually the wall should also have rock wool, 50 thick or 75 thick

- Q:PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q:Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- First cut off, after the cut off does not matter. Fixed the problem to your decoration workers. No headache. The First cut off, after the ceiling so that when the ceiling of the wall at the top of the site good handling. Cut off the height of more than 3 meters a few centimeters on it.

- Q:Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Light steel keel about 12-13 yuan, enough to do a square, gypsum board per square 16 yuan (double) or so, paint workers wages about 25 yuan. / Square (package workers package material); Labor costs about 18 yuan, all offer for 75 yuan or so.

- Q:House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Load on the best no problem with red brick, that wall how many square meters, if the area is less than 10 square meters can be brick 120 red brick wall

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Many temporary buildings will use wood keel to do with the wall, light steel keel more for long-term construction

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall System Stud Metal Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords