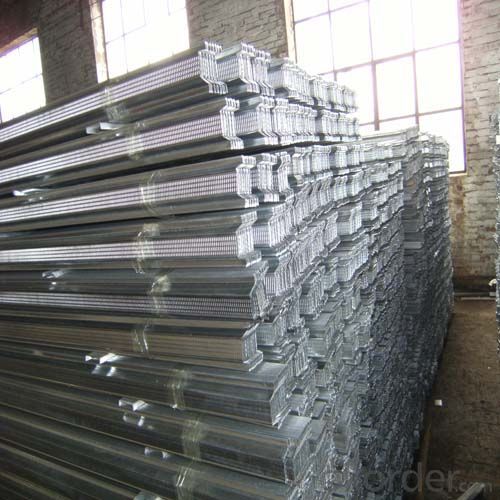

Drywall Partition Metal Stud Profiles Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

HUILON Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with HUILON magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Light steel keel gypsum board wall panels have cracks how to do?

- Many reasons caused by the pre-construction time may be the quality of gypsum board is not very good, and there is no wrong between the gypsum board, give you the proposal is to remove all the four sides of the seam, new plaster bandage, putty powder from the new Scrape, otherwise the other method is only a temporary solution,

- Q:How to fix the middle of the light steel keel to the roof and the ground, the keel has a joint?

- First with the expansion bolts fixed heaven and earth keel and roof and the ground, the middle with a vertical keel; if the layer is too high, then the keel will have joints, of course, have special connections.

- Q:Shanghai light steel keel ceiling wall how much labor costs?

- If you buy materials to make people do not directly specify the material model specifications, directly called light steel keel, specifically do fast and good.

- Q:Light steel keel wall to withstand the number of wind load

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places.

- Q:Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q:100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- You know how to do it If you want to do their own, you need to find the location of the wall light steel keel, and then a layer of woodworking board fixed to the light steel keel, and then do the partition in the woodworking board. Very simple, you may be confused

- Q:Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q:In Shanghai 75 partition wall light steel keel 0.6 what price now

- What brand to see it? Four brands are more expensive. Generally in the 7.5-9.5 a meter In the high-end 4.5-6.5 yuan / m

- Q:Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- 50-type light steel keel ceiling to pay keel by 400 open dragon licensing gypsum board 30 yuan per square is not labor costs. The final price or depends on what you choose what kind of top child, and if there is a complex shape that according to the design drawings Offer it. Search the general ceiling in about 200 or so. Hope to help you, hope to adopt.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Partition Metal Stud Profiles Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords