Drywall Partition Galvanized Metal Stud factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall partition galvanized steel stud price

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Detail description

1.Materials:galvanized steel strip

2.Thickness:0.4-1.2mm, size:90*40, 90*50

3.Length:2.8m,3.0m,3.2m or according to order

4.OEM steel keel service can be avaliable

5.Package: bundle package with plastic strip

6.Application; drywall partition

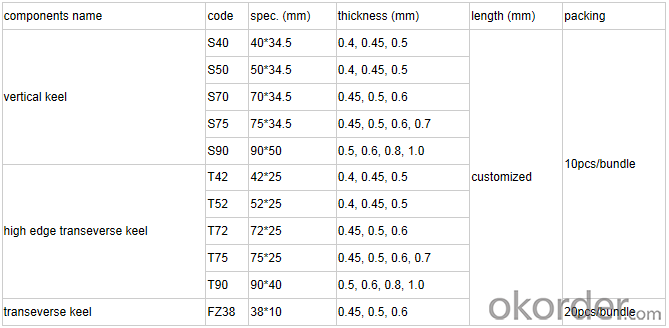

Specification

components of drywall system

Function and advantage

1.good quality, hot dip galvanized steel coil

2.light weight , easy install

3.surface: zinc coat, full with dot, high strength

4.strong bearing capacity, ametabolic

5.the production ability strong, 21 production lines-3200 tons per month

6.meet the GB standard

Package and delivery time

Packing-- 10pcs/bundle, nude package with plastic strip

MOQ- 10tons, can negotiate

Delivery time-- commonly 2 weeks after received the 30% deposit

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition can be said that the construction industry is now the forefront of science and technology, originated in Japan, because Japan is earthquake-prone countries, the seismic performance of the wall is very particular about, and high prices in Japan, Too high, so the house designers have invented the light steel keel inorganic composite board partition. Light steel keel inorganic composite board wall composed of light steel keel and double-sided inorganic composite panels, up and down wrapped sound insulation pad, with a solid and reliable, practical and practical features, and the thickness of only about 175px, 300px than the average wall thin. One inorganic composite board for the new inorganic composite materials, environmentally friendly materials, non-toxic and tasteless, excellent physical properties. It is composed of silicon, calcium and magnesium composite cementitious materials, and is applied by polymer composite technology. With fire-retardant, heat insulation, waterproof, waterproof, pest control, mildew, light, high strength, environmental protection and energy saving, construction fast, easy to finishes and so on. Light steel keel and inorganic composite board composed of light steel keel inorganic composite board partition wall as a partition, with strong earthquake resistance, sound insulation, easy to dismantle modification and space saving and other characteristics, a market will be favorable by the Japanese market , Has been widely used in foreign countries.

- Q:With light steel keel gypsum board do partition wall price how to count?

- Baoqing about 25, all 100-130 (material pricing).

- Q:Light steel keel partition wall construction process is what

- Processes: Bracket, Divider Pillow Pillow (Design Required) Fixed along the top, along the keel fixed Bone keel installation Vertical keel installation door, window frame installation Additional keel installation Support keel, check keel installation Electrical pipe , Installation of the installation of the wall equipment, a cover panel filled with sound insulation material installation, the other side of the panel panels and corners of the treatment of quality inspection.

- Q:Light steel keel wall and wood which low cost

- Do with the wall, then, certainly with light steel keel production is better. As for the cost, can be used to do the wall of the board, it should be relatively thick, so that its price will be more than the price of gypsum board, and then the cost of light steel keel equivalent.

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q:Gypsum board wall above the good paint glass?

- You said it is necessary to nail fixed it, should not be installed, mainly afraid of bearing no, long-term bearing gypsum board may not stand, as far as I know gypsum board wall generally do not do curtains, No, I think you said the weight of the paint glass is not light, it should not work, not installed.

- Q:100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- The following is the decomposition of the material (no loss), vertical wall keel spacing is generally @ 400, vertical keel is 2.5m / m2; along the top edge (heaven and earth) keel is 2/3 = 0.67m / m2; Piercing board is 4m2 / m2 partition wall area; large white putty is about 2.5kg / m2 partition wall area, latex paint is 0.5kg / m2 partition wall area. Brush twice to consider; the rest Is the card pieces, nails, bandages, white latex, high-strength nails and oblique support cable-stayed material (wood can be) and other auxiliary materials Usually the wall should also have rock wool, 50 thick or 75 thick

- Q:House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- Bathroom, bath and other multi-water room and high humidity room light steel keel gypsum board wall of the root, the application of C15 concrete to do 120mm high wall base. Gypsum board seams should be used by the manufacturers supporting the supply, dedicated to the joints with the caulking paste and cap joints to ensure that the quality of gypsum board joints.

- Q:Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- The general master of the price between 20-25 yuan, Bao Gong Bao material in the 100 yuan from top to bottom, home improvement light industry in 20-25 yuan, package package material between 300-600 good, about 100 yuan in general, said are Is the price per square meter. If their own live, according to the ceiling to do a good job, do not use too much rental, 40-50 yuan a tide of moisture on the skin from the sub-90 yuan -100 yuan per square meter, it is recommended to see the character, Friends of such a big brand, big brands and small brands of plate difference is not big, that is, the electrical difference is bigger, good to warm about 1,000 yuan, LED good 500-1000 yuan, ordinary 200-100 yuan, good ventilation Of the ventilation of 500-1000 yuan, the ordinary 200 yuan from top to bottom

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Partition Galvanized Metal Stud factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords