Drywall Metal Studs and Track Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Suspension System) Description

As an authorized trading facility, Shanghai Microcherry Information Technologies (MCI) focuses on providing high quality products by offering premium services to customers.

As the original manufacturer, Shanghai Hanhan Hardware Factory works with engineers having more than 15 years experience, and manufactures various types of galvanized light steel profiles for years, such as drywall & partition system, ceiling system, plasterboards, applying to all kinds of houses, hotels, factories production and sales integration.

2,Main Features of the (Suspension System)

Advantages of Galvanized Structural Steel Profile:

1. Raw material is high quality hot dipped zinc galvanized steel strip, good fireproof and heat insulation, waterproof and antirust, anticorrosive, high durability;

2. Hot dipped zinc galvanized steel strip zinc coating is 80-180g/m2;

3. Double sized galvanization volume make sure that the plaster bone is corrupt and rust resistance.

4. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have with an excellent reputation of high quality and services;

5. High quality raw material guarantees the light steel keel of life and good performance of construction;

6. Equipped with ten precision cold rolled steel strip production line;

7. Waterproof and antirust, anticorrosive, high durability

8. OEM is available.

9. Application:

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

3,(Suspension System) Images

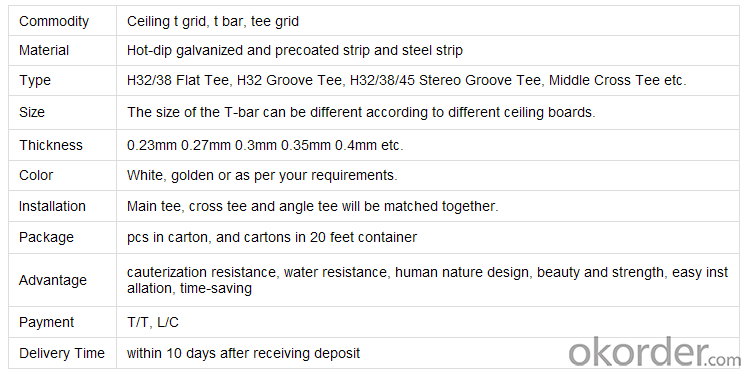

4,(Suspension System) Specification

5,FAQ of (Suspension System)

No.& Name | METAL STUDS & TRACKS |

Base Materials | 80g-120g / sqm galvanized steel |

SIZE | 38,50,60,75,100,150mm,thickness from 0.3mm-2.0mm. Can produce according to customer requirement |

Features | Good machine performance, high strength & light self-weight, fire-proof, dampproof, heat insulation ,high durability , high rust resistance, high-intensity and good-antisepsis |

Operating | Short-time instuction, easy working, it a new decorative material |

Function | Fit for shopping mall, hospital, offices, banks, hotel, facory, etc. |

Ceiling channel and drywall channel, made of high-quality galvanized Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling.

Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

- Q:Light steel keel wall how to calculate

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on. Process: In order to avoid the root wall vulnerable to moisture, deformation, mildew and other quality problems, the bottom of the partition to be made pillow base;

- Q:Light steel keel partition wall how to paint

- Personal feel that the painting will not affect the load bearing, as the choice of home painting should be bright, festive and music-based content, a symbol of wealth and wealth of peony painting, a symbol of the lotus and koi map, Healthy longevity of the pine and cypress Evergreen and so are more suitable for home furnishings. And should not hang some unexpected things, such as some works but too aloof, only to the collection, on the home as a decoration is not appropriate.

- Q:Light steel keel partitions and finished partitions

- Light steel keel partition is one of the most common decoration projects in the field of decoration and decoration. It is made of light steel keel as the basic skeleton, the surface gypsum board is made of wall layer and fixed to the top and top of the building. Wall; it needs to use talcum powder, such as putty layer, latex paint or wallpaper as a surface decoration, are produced on-site.

- Q:Light steel keel with what screws fixed gypsum board

- With fast wire. Fast wire: cone tip, countersunk head, cross marks, double wire with boiled or galvanized surface treatment. ?????? Fast wire that is fast teeth screws, usually usually belong to self-attack class.

- Q:Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel (generally with gypsum board) wall lightweight, easy construction, low cost, a large number of indoor partitions,

- Q:In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- Can be directly connected, but not solid. How are they all know what they are.

- Q:Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Light steel keel level can be used in the ceiling, can also be used in the partition, Wood keel can also be cut off the ceiling can be done.

- Q:Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Distance can be used with nail gun, more than 10cm above hanging with a large crane

- Q:What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Decorate the wood keel can be, and then use the integrated wall covered up on it. The other keels are too much trouble and time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Studs and Track Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords