Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

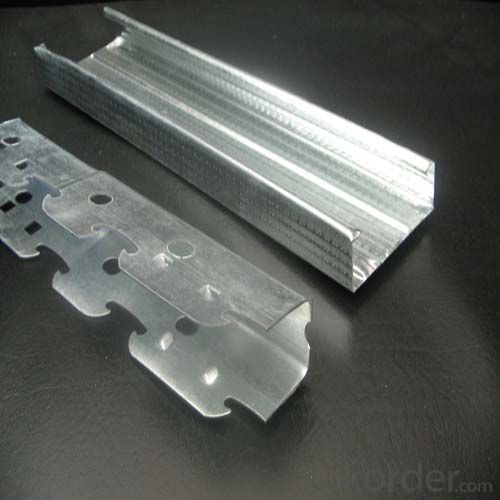

Australia drywall metal stud, drywall stud and track connection size:51/64/76/92/150mm ,thickness:0.55-1.15mm,galvanized z275g.

Australia metal drywall stud,1)Standard in Australia , 2)Thickness:0.5-1.5mm, 3)zinc coating:120-275g ,4)Very Perpendicular, 5)Support is fast construction, 6)Length size according to the customer size manufacture

Specification

PART NO | DESCRIPTION | Size(mm) | Length(mm) |

125 | 25mm Top Cross Rail | 25*21*0.55 | 3600/4800/6000 |

127 | 25mm Top Cross Rail | 25*21*0.75 | 3600/4800/6000 |

308 | 16mm Furring Channel Track | 16*20*30*0.55 | 3000 |

129 | 28mm Furring Channel Track | 28*20*30*0.55 | 3000 |

301 | 16mm Ceiling Batten | 36*16*0.5 | 4800/6000 |

303 | 22mm Cyclonic Ceiling Batten | 35*22*68*0.55 | 4800/6000 |

310 | 40mm Ceiling Batten | 35*40*70*0.55 | 4800/6000 |

308 | 16mm Furring Channel | 16*38*0.55 | 3000/3600/4800/6000 |

129 | 28mm Furring Channel | 28*38*0.55 | 3000/3600/4800/6000 |

401/489 | 51mm Stud | 51*33.5*35.5*0.55/0.75 | 2400/2700/3000/3600/4200/4800/6000 |

112/491/661 | 64mm Stud | 64*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

403/493/671 | 76mm Stud | 76*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

251/495/681 | 92mm Stud | 92*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

511/691 | 150mm Stud | 150*33.5*35.5*0.75/1.15 | 3600/4800/6000/7200 |

400/490 | 51mm Track | 51 * 32/50 * 0.55/0.75 | 3000 |

111/492/660 | 64mm Track | 64 * 32/50 * 0.55/0.75/1.15 | 3000 |

402/494/670 | 76mm Track | 76 * 32/50 * 0.55/0.75/1.15 | 3000 |

250/496/680 | 92mm Track | 92 * 32/50 * 0.55/0.75/1.15 | 3000 |

510/690 | 150mm Track | 150 * 32/50 * 0.75/1.15 | 3000 |

Leg Stopping Angle 6mm | 30*6*0.4 | 3000 | |

P25 | Leg Stopping Angle 10mm | 30*10*0.4 | 3000 |

P26 | Leg Stopping Angle 13mm | 30*13*0.4 | 3000 |

P27 | Leg Stopping Angle 16mm | 30*16*0.4 | 3000 |

P01 | External Angle 90 | 30*30*0.4 | 2400/2700/3000/3600 |

P50 | Shadowline stopping angle | 10*10*30*0.4 | 3000 |

PART NO | DESCRIPTION | Thicknes |

Adjustable Direct Fix | 1.5mm | |

Beta Fix | Beta Fix | 1.5mm |

Long Beta Fix | Long Beta Fix | 1.5mm |

167 | Side mounted TCR Suspension Clip | 0.8mm |

139 | Locking Key | 0.7mm |

2534 | TCR Suspension Clip | 0.8mm |

121 | 5mm Rod Suspension | 5mm |

305 | Direct Fix Clip -150 long | 1.0mm |

314 | Direct Fix Clip-92 | 1.0mm |

247 | Right Angle Rod Bracket | 1.2mm |

274 | R0d Brackets | 1.2mm |

Ceiling Bracket | 1.6mm | |

Floor Pin | ||

239 | Direct Fixing Clips—Screw Fix | 1.2mm |

237 | Direct Fixing Clips-Concrete | 1.2mm |

394 | Direct Fixing Clips 175mm | 1.0mm |

226 | Direct Fixing Clips 75mm | 1.0mm |

SWC3 | Slotted Web Cleat | 3mm |

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

- Q:Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a hammer to drill the ground hole can be fixed to the ground. With glue, it is certainly impossible to nail

- Q:Lightproof wall how to fire

- And light steel keel installation door is the same light steel keel door frame after doing the light steel keel and then do a fixed two-layer woodworking board as a door cover and then the fire door fixed in the woodworking board or in the light steel keel fixed channel steel Made the door sets and then fixed fire doors or not the first gypsum board in the light steel keel on the back of the fixed fire door or with a channel or angle or simply use a wooden fire door

- Q:Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q:Is it good for brick walls or light walls?

- If you do not have any requirements for noise, you can use light steel keel gypsum board wall, but can not hang things Oh, can not touch, easy to bad. And it's not fire at all. Home in the living room to do a small partition can also be, but used as a large room partition is not desirable

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- Bathroom, bath and other multi-water room and high humidity room light steel keel gypsum board wall of the root, the application of C15 concrete to do 120mm high wall base. Gypsum board seams should be used by the manufacturers supporting the supply, dedicated to the joints with the caulking paste and cap joints to ensure that the quality of gypsum board joints.

- Q:Light steel keel wall Why use gypsum board to do grass-roots level?

- Longgang wall: light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q:Curved gypsum board wall technology.

- If the curvature is not large, then the gypsum board can be bent directly over, the deformation of the gypsum board itself is enough, if the curvature is too large, then only cut the stitching, and then patch repair, no matter what method, Do not use anything evenly spray water and then bend into the arc, gypsum board wet water, the intensity is very low, although dry, the strength and good board is not very different, but there may be deformation of the plate

- Q:Light steel keel wall circuit how to wear pipe

- 1, to C-type vertical keel on the threading hole as the basis, first determine the direction of the upper and lower ends of the keel, try to align the threading hole. Vertical keel length size, should be measured according to the size of the scene. The premise is to ensure that the vertical keel can be along the ground, along the long keel slot slide. 2, light steel wall vertical keel installation spacing, according to the actual width of the panel size and wall structure design may be. 3, vertical keel installed in place, should ensure that the vertical. Door and window openings should be taken double row of vertical keel reinforcement. When the design requirements for the steel connection, the vertical keel and the edge along the top keel of the fixed, the application of self-tapping screws or shaft rivets to connect. sixth,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Metal Stud for Australia And New Zealand

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords