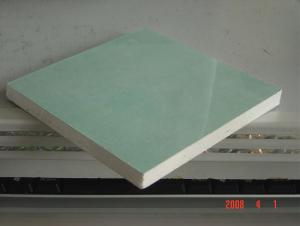

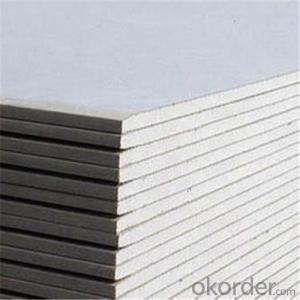

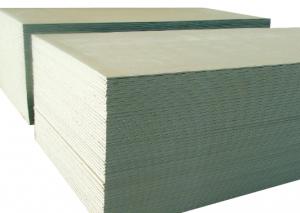

Drywall Gypsum Board

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Main Material: Gypsum Powder

Normal size: 2440x1220mm, 2400x1200mm

Normal thickness: 7, 8, 8.5, 9, 9.5,10, 12, 13, 15mm

Edge: Square, Tappered

Category: Regular, Fire resistant, Moistureresistant, Water proof

Performance: Fire-resistance, Moisture-resistance,Water-proof, Heat-preventing

Specifications:

1) Sepcial healthy breath function

2) Cost effective and more reliable, easy to install

- Q:Hi! I want to hang my electric guitars on my wall which is made of plasterboard! Each guitar with have it's own hanger with two screws holding it on the wall. I will also use plasterboard wall plugs to hold the screws in place> I am just wondering if the walls will be able to support the weight of the guitars at all or is this going to be a disaster? Thanks all!

- To be safe, I'd mount a stained or painted board on the wall with molly bolts (expanding screws that open on the inside of the wall) or screw it into the wall studs, then fasten your hanger into the wood of the board.

- Q:Menards doesn't have it, Home Depot doesn't have it, a local home building materials store doesn't have it. So where can I go to buy it? I don't want to order it online.

- Try a commercial drywall or masonry supplier

- Q:can you put a punch bag on plasterboard?

- Obviously you must mean plasterboard on brick? I am not certain but i am guessing this will cause cracks around the wall bracket and after time make cracks down the wall. Best answer if you could please.

- Q:Gypsum board does not brush the wall solid straight putty line okay

- Yes. Gypsum board is made through the keel as the main support, the surface fixed gypsum board. This structure, between the gypsum board will leave a seam (this is not a problem, but will certainly exist), so the first thing to solve is the crack crack. Gypsum board crack crack, need to use caulking products, while using kraft paper bandage as anti-cracking material. After doing this, the surface is best to seal once. Because the surface of the gypsum board is paper, the water resistance of the paper is relatively poor, it is easy to be blisters rotten. Do a good job after sealing, because the surface of the gypsum board is relatively flat, so do not need to do thick leveling, do fine leveling directly (that is, putty putty).

- Q:can i put 8ft by 4ft plasterboards on a ceiling?

- Yes drywall is usually about 99% of what they do put on ceilings in the usa...Do not spray that crappy popcorn on it(acoustic) as someone has suggested here..It will trap dirt on it..and when you try to sweep it off you will get popcorn all over..later on it is almost impossible to paint with a roller for itcan peel off in sheets(the popcorn)...so everything must be completely draped off and the paint sprayed on it...

- Q:I have a LG 32 Tv. I was wondering would you be able to put it on a plasterboard wall? If so how?

- you can do it but you have to make sure when you put the screws in that you actually hit the 2x4 studs in the wall if you don't it wont hold :0)

- Q:I'm having the kitchen done and are having plasterboards put up 'cos the plaster that is on at the moment is so old, dry and flaking off in large peices. Just wondered if these walls will be strong enough to hold up my wall units. Pleeeeeaaase let me know.

- plasterboards (AKA drywall, sheetrock) are not very strong, definitely not strong enough to hold kitchen cabinets by themselves. be sure that when you hang things like cabinets, shelves, etc from the wall that they are anchored to the studs and the frame of the house or else they will just tear out.

- Q:I have taken the old tiles off and scraped away the old adhesive, but in the process some of the paper coating (of the plasterboard) has come away in places; 95% of it looks ok but there are a couple spots where the plaster is showing through.Can I just put the adhesive on and use it as a filler too or should I be priming the plasterboard with something before I start putting on the adhesive and tiling ?OR what..I'm not after perfection here but I don't fancy having to re-tile it again in a couple of years because the tiles start falling off.

- If the plaster or dry wall is exposed, its best to either run some paint primer over it to seal it, Or fill it in with some dry wall compound or spackle and then primer it. This is especially true if your using a mastic to reapply tiles.If your using a thin set to apply tiles just a primer is needed to seal the exposed plaster or dry wall. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:how do i get tiles off a plasterboard wall?

- Is it wire mesh paster? If so you take two methods: one, beat it to death with a sledge hammer two- use a skill saw with combination blade (masonry-wood-metal) and cut into sections. Less dust and mess this way! Probably a bathroom wall?

- Q:is plasterboard and gyprock the same material and is it used for walls and ceilings.?

- Gyprock is a brand of plasterboard. Yes, you use it for walls and ceilings. For floors you need a stronger particle board.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Gypsum Board

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords