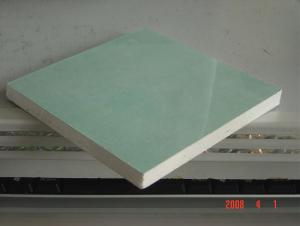

Drywall Gypsum Board with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Gypsum Board Drywall Introduction.

Your drywall can be virtually any shape, anywhere. Choose from a wide range of heavy-duty system options that provide code-compliant performance in both fire rated and non-fire rated applications with labor-saving advantages.

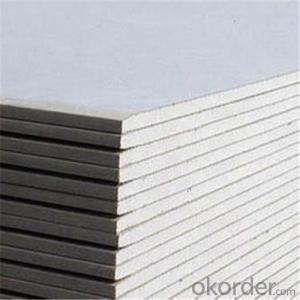

1.Gypsum Board Drywall Specification.

| Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

| Surface treatment | Paper/PVC laminated/foil back |

| Production capacity | 10,000m2/day |

7 .specification

SIZE(mm) | KGS/PC | PCS/20GP | SQM/20GP |

1200*2400*7 | 17 | 1180 | 3398 |

1200*2400*7.5 | 18 | 1150 | 3312 |

1200*2400*8 | 18.2 | 1080 | 3110 |

1200*2400*9 | 22.1 | 970 | 2793 |

1200*2400*9.5 | 22.8 | 940 | 2707 |

1200*2400*10 | 23.5 | 900 | 2592 |

1200*2400*12 | 29.5 | 720 | 2073 |

1200*2400*12.5 | 30 | 710 | 2044 |

1220*2440*7 | 17.55 | 1160 | 3453 |

1220*2440*7.5 | 18.14 | 1130 | 3363 |

1220*2440*8 | 18.58 | 1060 | 3155 |

1220*2440*9 | 22.83 | 950 | 2827 |

1220*2440*9.5 | 23.55 | 920 | 2738 |

1220*2440*10 | 23.83 | 900 | 2679 |

1220*2440*12 | 30.5 | 700 | 2083 |

1220*2440*12.5 | 31 | 690 | 2053 |

2.Gypsum Board of ceiling & wall partition system.

CMAX System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable

Durable and Standard Quality

Lightweight, Easy to Install and Economic

Applicable to Various Usages as Required

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

- Q:can i tile straight on plasterboard?

- if you want to do a proper job and not cut corners like most jack-legs do.you must apply a product called hardy board over the plaster and be sure to screw into the wall studs.then apply your tile on top of that.it will last a very long time and you will feel proud of a job well done.

- Q:Hi! I want to hang my electric guitars on my wall which is made of plasterboard! Each guitar with have it's own hanger with two screws holding it on the wall. I will also use plasterboard wall plugs to hold the screws in place> I am just wondering if the walls will be able to support the weight of the guitars at all or is this going to be a disaster? Thanks all!

- No, they are not that much strong to hold a heavy guitar. If your guitar is light weight only then you should hang it there.

- Q:Why can gypsum board can be flame retardant

- Two layers of paper, the middle gypsum powder, the raw material itself is noncombustible

- Q:How do you paint a stone on a gypsum board?

- Gypsum board spray really need to carry out the bottom of the stone processing Caixing, can not directly spray real stone paint

- Q:how do you hold insulated plasterboard on the ceiling while you drill it?

- you have about 3 choices..... rent a stand you put the bord on it then hand crank it to the cieling......or get some 1 to help you....or make a tool its just a couple of 2x4's nailed together to form a T make the long part of the T a little bit longer and just kick it in on a slight angle

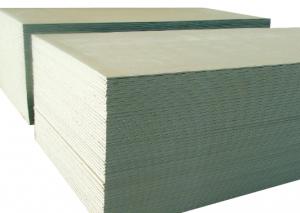

- Q:How to identify waterproof gypsum board and general gypsum board?

- Very simple ah! General gypsum board are paper waterproof is no paper! There is also a waterproof gypsum board gypsum is yellow very hard and accompanied by particles. General gypsum board gypsum is pure white is very delicate and very soft

- Q:What is the thickness of a single layer of light steel keel gypsum board?

- Generally 9.5MM, but there will be worse, will be a little bit a few millimeters

- Q:Which brand of gypsum board is best suited for home improvement?

- Foreign brands: 1, Saint-Gobain gypsum building materials 2, Lafarge 3, can be resistant to Fuk Domestic brands: 4, Long card - North New Building Materials 5, Taishan gypsum board 6, Jason 7, Bayer baier 8, bunny 9, snow abundance xuefeng 10, Fort de Gypsum board Among them, the quality of the three foreign brands better than domestic, the quality is relatively high. Several domestic brands of good and bad quality, need to carefully selected.

- Q:Waterproof practices of light steel keel gypsum board partition wall

- In the purchase of gypsum board material, it is recommended to buy waterproof gypsum board can be Existing ordinary gypsum board, fire gypsum board and waterproof gypsum board. Waterproof gypsum board refers to the slab in the United States under the ASTM standard for waterproofing test, the water absorption rate of 5%, that can be used for large areas of humidity, such as the bathroom, shower room and kitchen, the board is in the gypsum core Material to add a quantitative waterproofing agent, so that the plaster itself has a certain waterproof performance. In addition, gypsum board paper is also waterproof, so this is a better use of a wider range of plate. But this board can not be directly exposed to the wet environment, nor direct water immersion for a long time. Practice: waterproof gypsum board back brush waterproof paint, front scratch waterproof putty, brush waterproof latex paint Light steel keel: light steel keel gypsum board wall commonly used light steel keel system has three; 1) LL-no accessory system. It LLQ-U, LLQ-C keel composition of the partition skeleton and LLQ-CK keel composition of the sub-wall skeleton, can increase the height of the wall and increase the skeleton strength. 2) QL - have accessories. To C1, C2 keel-based pieces with a continuous cross-keel, support cards, brackets and other components to strengthen the keel partition wall skeleton. 3) QC - no accessory system (if necessary, also available accessories). To QU, QC keel composition of the partition wall skeleton. Can increase the wall height to enhance the wall strength. Can also be cultivated through the cross-keel, supporting cards and other accessories composed of partition skeleton.

- Q:Can those JML pull up bars be used on a wall that isn't brick?

- there's a video, and it's used on a regular door. reviewers all say it hasn't taken any damage / caused any to their door.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Gypsum Board with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products