Drywall for Constuction Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

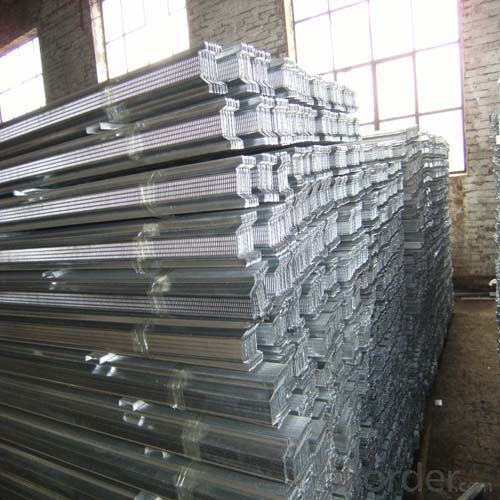

Drywall for Constuction Building Material

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Detail description

1.Materials:galvanized steel strip

2.Thickness:0.4-1.2mm, size:90*40, 90*50

3.Length:2.8m,3.0m,3.2m or according to order

4.OEM steel keel service can be avaliable

5.Package: bundle package with plastic strip

6.Application; drywall partition

Specification

components of drywall system

Specification for middle east:

Main Channel 38*12

Furring Channel 68*35*22

Wall angle 25*25

C stud 50*35

C Stud 70*35

C stud 75*35

U track 52*25

U track 72*25

U track 75*25

Specification to Australia:

top cross rail 25*21*0.75

25*21*0.75

Furring Channel 28*38*0.55

16*38*0.55

Furring Channel track 28*20*30*0.55

16*20*30*0.55

Stud 64*33.5*35.5

76*33.5*35.5*0.55

Stud 92*33.5*35.5*0.55

150*33.5*35.5*0.55

Track 51*32*32, 64*32*32*0.55

76*32*32*0.55

Track 92*32*32*0.55

Specification to Europe, Russia; Ukraine;Georgia. ect

C Stud 60*27

U track 28*27

C stud 50*50

C stud 75*50

C stud 100*50

U track 50*40

U track 75*40

U track 100*40

Package and delivery time

Packing-- 10pcs/bundle, nude package with plastic strip

MOQ- 10tons, can negotiate

Delivery time-- commonly 2 weeks after received the 30% deposit

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q:Light steel keel wall to remove the price

- Fixed price: the state has a demolition quota, but the price is very low, generally can not afford to be fixed. Now some parts of the decoration quota also have to remove the sub-head, slightly higher than the demolition quota, but no profit.

- Q:Shanghai light steel keel ceiling wall how much labor costs?

- Do not know how much of your area may be a little expensive point of the ceiling 10 yuan / square wall 80 / side less expensive to the point is not the same everywhere, roughly in the 20 to 25 or so labor price.

- Q:What is the pros and cons of a brick or a gypsum board?

- Wall, then the sound is very important, otherwise the side of the talk there all heard, this wall is very embarrassing. Light gypsum board, of course, can not be soundproof, the key is to choose the appropriate sound insulation cotton, and now people are more popular in the interior decoration is the gradient of sound-absorbing cotton, from environmental protection, fire, sound-absorbing efficiency and other considerations, gradient sound-absorbing cotton are present Home, office decoration more appropriate, such as the larger domestic conference center are using this sound insulation material.

- Q:75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Must do 75 keel, it is recommended to add angle iron or square tube reinforcement, do not forget to do heart keel

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q:Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q:The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- It is possible that you said that the wall above is a beam, so that when you remove the wall, the gap between the two ceilings to do a false beam to solve. But if this place did not beam, then we must consider the demolition or not split!

- Q:How to install light steel keel gypsum board wall

- Gypsum board installation, should be used in vertical arrangement, keel gypsum board should be wrong on both sides. Gypsum board and keel can be fixed with self-tapping screws. 12mm thick gypsum board with 25mm long self-tapping screws; two 12mm thick gypsum board with 35mm long self-tapping screws. Self-tapping screws from the edge of the gypsum board should be at least 10 mm in the board edge of the paper, at least 15 mm in the cut edge of the board. The screw cap should be buried inside the board, but no damage to the paper. Self-tapping screws from the center of the board should be 250mm, in the middle of the board should be 300mm.

- Q:Lightproof wall how to fire

- Light barrier If you need to do fire, you must meet three conditions: stability, integrity, heat insulation;

- Q:Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Distance can be used with nail gun, more than 10cm above hanging with a large crane

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall for Constuction Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords