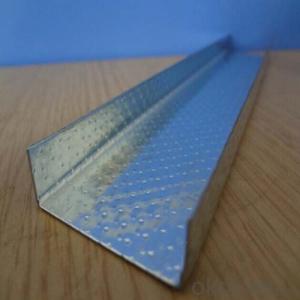

DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

1>adopting high-grade quality hot-dipped galvanized steel,

2>The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

FAQ

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method. 8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price *large quantity *honesty *good after-service

9.Certificates ISO 9001:2000 Quality management system

- Q:Light steel keel wall how to calculate

- According to the actual calculation of the amount of work to square meters for the calculation unit, the price of both sides negotiated or set quotas. According to how you talk about the calculation, if not talk, the market is calculated by single-sided!

- Q:Gypsum board partition wall how to sound insulation

- Brush the EL1230 interface agent with hungry wolf adhesive paste Yanmian insulation board, and then apply anti-cracking mortar protective layer.

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q:Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q:How to install light steel keel gypsum board wall

- Gypsum board installation, should be used in vertical arrangement, keel gypsum board should be wrong on both sides. Gypsum board and keel can be fixed with self-tapping screws. 12mm thick gypsum board with 25mm long self-tapping screws; two 12mm thick gypsum board with 35mm long self-tapping screws. Self-tapping screws from the edge of the gypsum board should be at least 10 mm in the board edge of the paper, at least 15 mm in the cut edge of the board. The screw cap should be buried inside the board, but no damage to the paper. Self-tapping screws from the center of the board should be 250mm, in the middle of the board should be 300mm.

- Q:The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q:Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Have to do, nothing can not, but not a good idea. The feeling of the glass is bright and transparent. Light steel keel specifically suitable for installation, the concealed keel with transparent glass display will be what effect.

- Q:In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- Can be directly connected, but not solid. How are they all know what they are.

- Q:What is the light steel keel gypsum board partition? What are the characteristics?

- According to the Austrian decoration experience, light steel keel gypsum board wall with simple construction, light, strong, fire-retardant, thermal insulation and other characteristics, the keel sub-vertical keel and horizontal sub-keel, commonly used width of 65,75, Can be fixed with self-tapping screws on the main keel. Keel can be filled with rock wool and other insulation materials.

- Q:How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords