Double-Stage Efficient Rotary Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1,Material:Aluminum Alloy casing2,Pumping speed:6/7Cfm

3,Warranty:1 year.

4,Minimum order:1 set.

◊ Application

RS Series vacuum pump is compact, light and attractive in design. It uses the big starting torque and is specially designed for low temperature environment. It is guaranteed start normally in winter’s low temperature. It is applicable to vacuum packaging, vacuum freez

This kind of pump is widely used in food packaging, scientific research, medical treatment, electronics, chemicals, medicine and laboratory of universities and colleges.

ing, automobile reparation, gas analysis, medicine mechanism, printing mechanism and other vacuum evacuations.

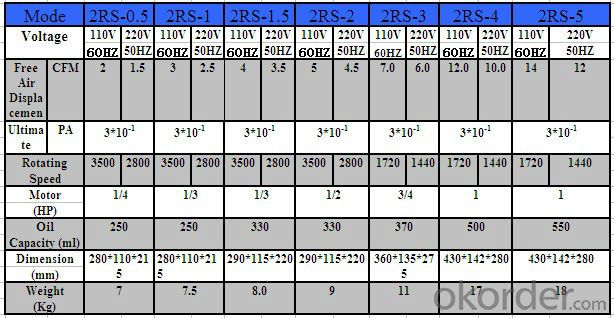

◊ Technical data

◊ Products' picture

- Q:What are the differences between the sewage pump and the clean water pump?

- The main difference between the sewage pump and the clean water pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.

- Q:Centrifugal pumps for normal operation, is it reasonable to install valves on their inlet lines? Why?

- Submersible pump is best in the water, if dry pumping will cause burns.

- Q:The function of centrifugal pump

- 2, pump body, also known as pump shell, it is the main body of the pump. The utility model is provided with a supporting and fixing function and is connected with a bracket for mounting the bearing.3, the role of the pump shaft is to use the coupling and motor connected, the motor transfer distance to the impeller, so it is the transfer of mechanical energy of the main components.

- Q:What is the difference between the ground pump and the pump in the commercial concrete?

- What you should say here is the concrete pump.Ground pump: the pump will be placed in a position on the site, the pipeline will be sent to the construction of concrete surface,

- Q:Why can't the centrifugal pump pump the vacuum?

- Working principle (taking centrifugal pump as an example):Prerequisites, processes, and requirements for the overall system structure.

- Q:How many kinds of pumps are available and the operating principles of various pumps?

- There are many kinds of pumps. There are different classifications according to different standards. If classified according to the principle of work, can be broadly divided into the following four categories:1, vane pumps: centrifugal pumps, axial pumps, mixed flow pumps, vortex pumps, etc.;2, displacement pumps: piston pumps, piston pumps, diaphragm pumps and so on;3, power rotary pump: screw pump, gear pump, etc.;4 、 special function: jet pump, water hammer pump, magnetic drive pump, etc.;

- Q:What is the displacement of the pump? Flow? What is the volume efficiency and mechanical efficiency of the pump?

- Pump flow: the volume of liquid discharged per unit time.(3) volume efficiency of pump: the ratio of actual output flow of pump to theoretical flow rate.

- Q:The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- 1. submersible pumpsA very wide range of water treatment tools. Unlike ordinary water pumps, it works underwater, while the pump works mostly on the ground.The working principle of submersible pumpBefore the pump is opened, the suction pipe and pump must be filled with liquid. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet, the outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuously from the outflow discharge tube.Basic parameters of submersible pumpIncluding flow, lift, pump speed, matching power, rated current, efficiency, diameter and so onSubmersible pump main application and scope of applicationIncluding construction, construction, drainage, agricultural irrigation and drainage, industrial water recycling, urban and rural residents cited water supply, and even rescue, disaster relief and so on

- Q:What are the starting and stopping procedures for centrifugal pumps?

- Before using the centrifugal pump, the operation instructions of the centrifugal pump shall be read carefully and the specific operation procedures shall be understood so as to make proper use of the centrifugal pump products. The first step is the operation of centrifugal pump inlet valve of centrifugal pump centrifugal pump for all open cavity filled with liquid, close the outlet valve, start the motor, the motor speed is normal, can gradually open the outlet valve, to adjust to the desired condition. Pay attention to self suction centrifugal pump starts to open the exhaust valve, outlet valve should be opened quickly in the normal operation of the motor, to prevent air inlet pipe off caused by cavitation phenomenon produces centrifugal pump, centrifugal pump vibration phenomenon leads to noise of the smoke is not on the water.

- Q:What is the liquid pump? What are their categories? What are their strengths and weaknesses?

- The liquid pump can be filled with oil, water and chemical medium. The gas drive range of the liquid pump is 1 to 10bar (14.5-145psi). The bottom piston is controlled by a two position four pass pilot valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double-Stage Efficient Rotary Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords