Double Sided Tissue Tape 100 Micron SGS&ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

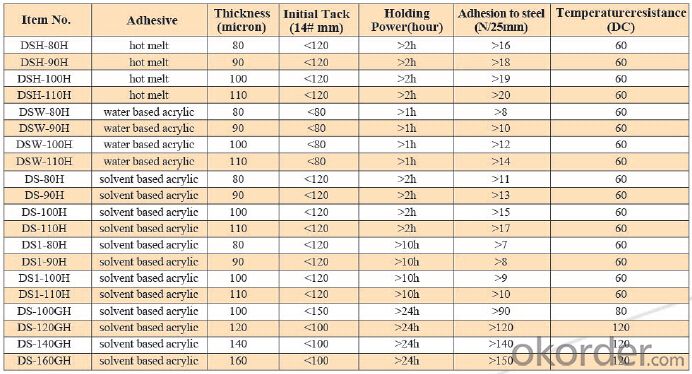

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q:Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q:Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q:How does packaging tape perform on recycled or eco-friendly packaging materials?

- When it comes to recycled or eco-friendly packaging materials, packaging tape tends to perform well. The performance of the tape, however, will ultimately depend on the specific type of material being used. Recycled packaging materials, like cardboard or paper, typically have a rougher surface than traditional packaging materials. Nevertheless, packaging tape is specifically designed to stick to various surfaces, even those with different textures. As a result, it should adhere well to recycled materials without any major issues. Eco-friendly packaging materials, such as biodegradable or compostable plastics, may possess slightly different properties in comparison to traditional plastics. Nonetheless, most packaging tapes are designed to work effectively with different types of plastics, including eco-friendly options. It is crucial to ensure that the packaging tape you select is compatible with the specific eco-friendly material you are utilizing. In general, packaging tape is created to provide a secure and reliable seal on packaging materials, regardless of whether they are recycled or eco-friendly. However, it is always advisable to test the tape on a small area of the material prior to applying it to the entire package. This will help ensure proper adhesion and compatibility.

- Q:Does packaging tape come in different textures?

- Yes, packaging tape does come in different textures. While the most common type of packaging tape is smooth and glossy, there are also textured variations available. Some examples of textured packaging tape include rubberized tapes, which have a soft and grippy texture, and paper-based tapes, which have a rougher texture similar to masking tape. These textured tapes are often used for specific purposes, such as providing extra grip or adhering to difficult surfaces. However, it's important to note that textured packaging tapes may have different adhesive properties and may not be suitable for all applications.

- Q:Buy adhesive tape every time, discover its sticky viscosity is insufficient, encounter cold weather, do not use well,

- Peel strength test: tape, stick to specific steel standard width, then the tape from the plate on the tear tape with the robot manipulator, a stabilizing force is reflected in the size of the peeling force.

- Q:How do I prevent packaging tape from tearing during removal?

- To prevent packaging tape from tearing during removal, there are a few strategies you can try: 1. Apply heat: One effective method is to use a hairdryer or heat gun to warm up the tape. The heat softens the adhesive, making it easier to peel off without tearing. Be careful not to overheat or burn the tape, though. 2. Use a cutting tool: If the tape is difficult to remove, you can use a sharp cutting tool like a utility knife or scissors to carefully cut through it. This way, you can avoid tearing the tape and remove it in smaller, more manageable sections. 3. Slow and steady approach: Take your time and be patient when removing the tape. Pull it slowly and at a low angle, applying gentle pressure to avoid tearing. If you encounter resistance, stop and try a different angle or apply a bit of heat to loosen the adhesive. 4. Seek assistance from a solvent: If the tape is particularly stubborn, you can try using a solvent like rubbing alcohol or adhesive remover. Apply a small amount to a cloth or cotton ball and gently rub it on the tape to dissolve the adhesive. Test the solvent on a small, inconspicuous area first to ensure it doesn't damage the surface. 5. Choose the right tape: Using high-quality packaging tape can also help prevent tearing during removal. Look for tapes with strong adhesion and good tensile strength. Reinforced or heavy-duty tapes tend to be more resistant to tearing. By employing these techniques and being cautious, you can successfully remove packaging tape without tearing it.

- Q:Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. Packaging tape is designed to have a strong adhesive that adheres well to various surfaces, including foam and bubble wrap. By applying packaging tape to the edges or seams of foam or bubble wrap, you can securely seal and protect your items during shipping or storage. It is important to ensure that the tape is applied properly and firmly to provide a tight seal and prevent the foam or bubble wrap from coming loose.

- Q:Are there any specific instructions for reusing packaging tape?

- Yes, there are a few specific instructions for reusing packaging tape. Firstly, ensure that the tape is still in good condition and is not torn or damaged. Gently peel off the tape from the package, being careful not to rip it. Next, find a clean surface to roll the tape onto, such as a smooth piece of cardboard or a tape dispenser. Avoid folding or crumpling the tape as it may lose its adhesive properties. Finally, when reusing the tape, make sure to press it firmly onto the new package to ensure proper adhesion.

- Q:Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Indeed, packaging tape can certainly serve as a means to seal packages containing medical or pharmaceutical items. Nonetheless, it is crucial to take into account the precise requirements and regulations pertaining to packaging within the medical and pharmaceutical sectors. Such industries often uphold rigorous standards concerning packaging materials, aiming to guarantee the safety, soundness, and adherence to regulatory guidelines of the products. Consequently, it is advisable to opt for packaging tape specifically formulated and authorized for use in medical or pharmaceutical contexts. These tapes are typically composed of moisture-resistant and tamper-proof materials, ensuring a robust seal to safeguard the package's contents. By utilizing approved packaging tape, the quality and integrity of medical or pharmaceutical products can be preserved throughout storage and transportation.

- Q:What are the benefits of using easy-release packaging tape?

- There are numerous benefits to using easy-release packaging tape, which can greatly simplify the packaging process. Firstly, this type of tape is designed with a low adhesion level, making it easy to remove without leaving any residue or damaging the applied surface. This is especially useful when packaging delicate or valuable items, as it guarantees damage-free removal. Moreover, easy-release packaging tape also saves time. It can be quickly applied and removed, increasing efficiency and saving valuable time for individuals or businesses that frequently package and ship items. Its user-friendly nature also reduces the risk of mishaps or errors during packaging, resulting in a smoother and more streamlined experience. Additionally, the ease of release provided by this tape makes it environmentally friendly. Since it can be easily removed without any sticky residue, it reduces the need for excessive cleaning or scraping, which can be time-consuming and may require the use of harmful chemicals. This not only benefits the environment but also cuts down costs associated with cleaning supplies and labor. Lastly, easy-release packaging tape offers versatility. It can be utilized for a wide range of applications, such as sealing boxes, securing packages, or bundling items together. The tape is often available in different sizes and materials, enabling users to choose the most suitable option for their specific needs. In conclusion, the advantages of using easy-release packaging tape include effortless removal without residue or damage, time-saving properties, environmental friendliness, and versatility. These benefits make it an excellent choice for anyone aiming to simplify their packaging process and ensure a stress-free experience.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double Sided Tissue Tape 100 Micron SGS&ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords