Double Impeller Centrifugal Pump

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double Impeller Centrifugal Pump

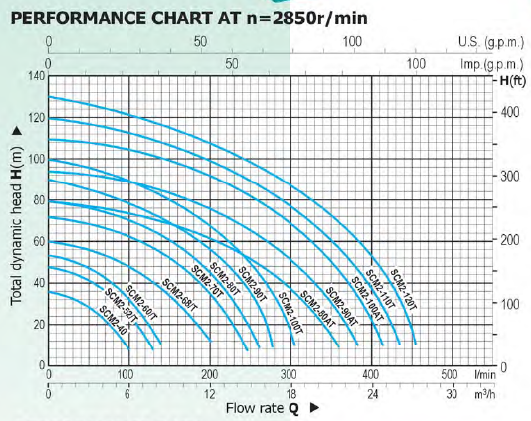

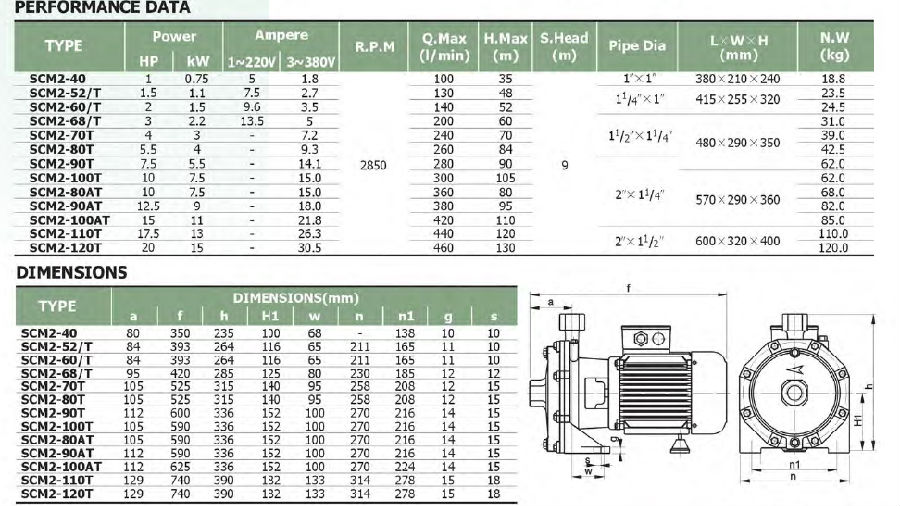

The SCM2 series are with two back to backimpellers, It is used for high head values, but if hard to reach with single impeller centrifugal pump.Suitable for civil and industrial uses to pump clean water and chemically non-aggresived liquid.Particularly be used for increasing for supply pressure, feeding boilers and loading extremely. These pump should be installed in a covered area, protected against the weather.

Pump body:Cast Iron

Impeller: Double brasss impeller

Motor:Closed, Externally ventilated

Insulation class:B(Class F if required)

Protection class: IP54/IP55

Duty:Continuously rated

Mechanical seal:Φ16, Φ18,Φ25 silicon carbide/graphite

Shaft:Stainless steel AISI 420

The normal power standard is 220v,50HZ,single phase

Three phase 220v/380v, 50HZ, 220V/460V, 60HZ

Single phase 230V, 240V, 127V,110V,115V/ 60HZ

Models are avaliable on request.

- Q:on my 92' toyota celica, i got the heater core by pass fixed and also a new radiator because both were leaking, and now my mechanic tells me i also need a new water pump , which can be really expensive! apparently it is leaking water too, so i was thinkng just filling up my car with water before driving until i can afford to get it fixed.. can this shortcut be done to prevent my water pump causing me further problems?

- in most cases when the water pump starts to leak water then its going out. there is no way to know how long it will last but you dont want to drive it long this way. water pump prices are not usually that bad the last one i bought (chevy s-10) was less than $40. not sure what the price for your car will be but if you can do it yourself then it will save you a lot of money.

- Q:honda acord water pump 1988

- hello Purchase a how to book, because part of the water pump sits behind the timing belt cover.Hope this was some help.

- Q:Was I supposed to lube the water pump or what. I really don't know what it could be making the noise now. But it goes away after about 5-25 seconds of running, what could it be?

- Check closely, you may find that the pulleys are not lined up completely. Have you had the power steering pump replace? Very common to have the pulley not pressed on completely, causing the ribbed belt to not ride properly on the pulley, causing squeaks.

- Q:can stress from to much weight cause the engine to get hot and cause your water pump to leak out the weep hole? and what else causes it to leak?

- There is a number of reasons for your water pump to leak. One could be its tear and wear due to years of used. Second is due to successive overheating. Weight cant cause water pump breakdown, as long as it does not overheats. To much pressure in the cooling system cause its breakdown. Hope this might help!

- Q:First I need to take off the belt, remove power steering pump, remove water pump bolts (the bolts are various length), remove water pump pulley (from old pump), install pulley on new pump, install new pump (with gasket and bolts in the right holes), install power steering pump, install belt. Is this the correct order? Can somebody throw any tips at me (somebody who has done it on this vehicle). It's a 2001 WJ with a 4L.

- The centrifugal pump is the most popular water pump in mining industry, it’s could be driven by the electric motor or by diesel engine. This water pump consist shell, impeller, and flange. It gets the advantages of simple structure, easy for maintenance, with high capacity and high lift meter. Application: The centrifugal pump is widely used in mining, coal, metallurgy, building material industry, and other industries which need transfer water or other liquid.

- Q:The dealership wants nearly $500. to replace the water pump in our 2002 Tahoe (5.3) it's leaking from the weep hole. I'm somewhat mechanically declined, what precautions will I need to know and any special tools to do the job myself? I've done a few water pumps back in the 1980's that didn't leak Thank you

- The dealerships are ridiculous. You probably need a ratchet and a couple sockets. You've done a water pump before? A water pump is still to this day, just a water pump. The difference is in where they put them nowadays. I don't know what kind of engine is in a 2002 tahoe, but I'm pretty sure it's not trans-mounted. So get in there, pull that sucker out, and replace it! Come on, you've done it before. And pick up a Hanes manual at the auto store. It will even walk you through the process, they come in very handy. I'm a mechanic, and I buy a Hanes manual for every car I own.

- Q:I just move to this house, it's been empty for a while. The water pump keep screeching everytime I turn it on. What can I do to get rid this noise?

- Is there water in the system? Pump bearing worn Find a bleed point on the pump and vent any air from it with the pump Off.

- Q:I need a 12v water pump capable of at least 40psi. The only website that i found is one where you have to order a minimum of 100.

- You can buy pressure pumps from HIMIN SOLAR CO.,LTD, SUN MOON MANSION, SOLAR VALLEY ROAD, ECONOMIC DEVELOPMENT ZONE, DEZHOU CITY, SHANDONG,CHINA.

- Q:My water pump in my pontiac bonneville 99 went bad, and while I was in the navy, in aviation fuels, some of my job consisted of repairing pumps and valves, and rebiulding them all together, and this water pump from my car seems to have some of the same features of previos pumps i've worked on, usualy when i use to repair pumps, most of the time i just replaced the bearings, just wondering if its do-able, im looking for the cheapist way to fix this, the casing for the pump seems to be in very good condition, but havent got it out of my car yet, im short on tools right now for the moment... thanks in advance for any help...

- Dont waste your time rebuilding it, just buy one from napa or some auto parts place with a life time warrenty, on something like that your time is worth more then the water pump, and since the pump is having to deal with hot water and corrosion it's possible it might go out again soon or never but with the warrenty it wont hurt so bad.

- Q:About how to calculate the pump installation height?

- When the water temperature is 4 degrees centigrade, the water pump is installed on the theoretical height of 10.33 meters, is the atmospheric pressure to the hydraulic pump inlet to the level of theory, in practical engineering, the water flow in the pipeline will produce resistance and other factors, the actual installation height generally less than 7 meters. The installation height limit of the pump shall be less than the design suction stroke of the pump.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double Impeller Centrifugal Pump

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords