Double Glass Mono(Poly) Crystalline silicon Solar Panel Model CR090M-B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Double Glass Mono(Poly) Crystalline Silicon Solar Panel Model CR090M-B

Double glass Mono(Poly) crystalline silicon solar panel(hereinafter refferred as "double glass solar panel" ) has advantage of beautiful apperence and high transmissivity by using the double glass on both sides of the solar panel, compared to the normal crystalline silicon solar panel. So double glass solar panel is widly used in the BIPV and other constructions such as solar intelligent window, solar pavilion and photovoltaic glass roof and wall.

2. Main Features of Double Glass Mono(Poly) Crystalline silicon Solar Panel Model CR090M-B

High-efficient solar cells

High transmissivity low-iron toughened glass

Anodized aluminum frame

Water resistant junction box

Design to meet unique demand of customer

25 year poweroutput warranty

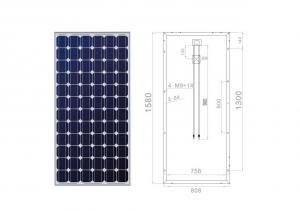

3.Double Glass Mono(Poly) Crystalline silicon Solar Panel Model CR090M-B Images

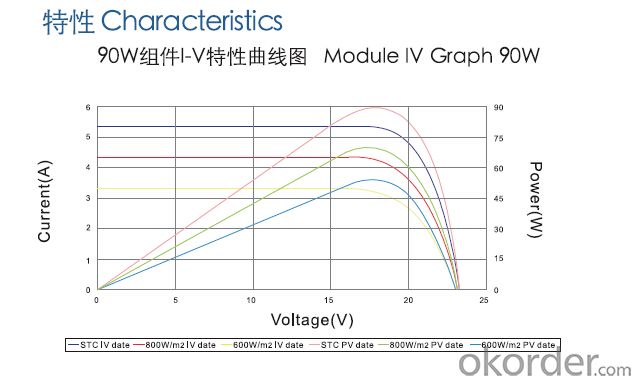

4. Double Glass Mono(Poly) Crystalline silicon Solar PanelModel CR090M-B Specification

MODEL | CR090M-B |

Maximum Power (Pm) | 90W |

Open-circuit voltage (Voc) | 22.2V |

Short-circuit current (Isc) | 5.29A |

Volatage at Pmax (Vmp) | 18.3V |

Current at Pmax (Imp) | 4.92A |

Maximum system voltage | 1000VDC |

Operating temperature | -40℃ to +60℃ |

Dimension of module(mm) | 1574×802×8 |

Weight of module (kg) | 23.0 |

Power tolerance | ±5% |

5. FAQ

(1) Why the double glass solar panel is more expessive than normal solar panel?

Because manufacturerer should face the technical difficulty in encapsulation process, and it costs more to make a lot of experiment to find a good packaging technology and get an excellent packaging method.

(2) How long for the manufacture process?

It depends on the payment terms, for we need to arrange the purchasing materials especially for the glass. If possible we prefer 100% by T/T to other payment terms, and we will put into production as soon as possible.

(3) Can we have test report of the solar panels?

Surely you can, once we have finished quality test after production, we have the technical details for the test report.

- Q:I don't want to spend a fortune, maybe talking like over $200 but I would like to power my computer, the monitor, my tv, and a small fridge.I looked up the price on some but it does not make any sense to me because it says that it has reached the price of less than $ per watt but if I look up a 20 watt solar panel it is $560 dollars. Why would it not be $20 because they said $ a watt.Where would be the best place to buy the cheapest solar panels?

- Today the lowest cost is more like $3 a watt. And you need to shop well to get it that cheap. The solar industry hopes to drive the cost down to $ a watt with the new thin film technology, but production volumes are still too low with that new technology for the market prices to come down. Their goal is to hit $ a watt within 5 years.

- Q:Can solar panels be installed on commercial buildings?

- Yes, solar panels can be installed on commercial buildings. In fact, many businesses and organizations are increasingly opting for solar panel installations to generate clean and renewable energy, reduce energy costs, and demonstrate their commitment to sustainability.

- Q:Can solar panels be installed on remote or off-grid locations?

- Yes, solar panels can be installed on remote or off-grid locations. In fact, they are particularly suitable for such locations as they do not require a connection to the traditional power grid. Solar panels can generate electricity by harnessing sunlight, making them a reliable and sustainable energy source for remote areas.

- Q:Can solar panels be used for powering agricultural irrigation systems?

- Yes, solar panels can be used to power agricultural irrigation systems. Solar energy can be converted into electricity through photovoltaic cells, which can then be used to power irrigation pumps and other equipment needed for agricultural irrigation. This offers a sustainable and cost-effective solution for powering irrigation systems, especially in remote agricultural areas where access to electricity may be limited.

- Q:I'm looking for some advice on hot water solar panels. I'm trying to save some money on electricity. A neighbor has been suggesting solar powered equipment for some time now, and I think he's right. It does save quite a bit of money in the long run. They're kind of expensive though, so I'm looking for cheaper alternatives.

- I worked for a plumbing service that offered hot water solar panel installs and replacements. I've replaced perfectly good solar panels for people who wanted to upgrade to the latest. We had piles and piles of panels out behind the shop. We use to scrap the copper and sell the glass panes. A few people would ask to scavenge panels and the boss would let them have it cheap, just to move some of the stuff. I would do the same. I'd find a local installer and see what they do with the leftovers. Chances are, if you searched diligently, you could probably find panels in good shape and use them to supplement your energy usage. Bear in mind, solar hot water system are very different from standard systems. They usually have a much larger storage tank. Typically 80-20 gallons compared to 40. They have a circulating pump and temperature sensors to move the heated water from the panel into the tank. These larger hot water heaters/tanks have much better storage and insulation to keep the water temperature that is generated during the day to last into the evening when people are home to use the shower and wash clothes to take advantage of solar heat. It's not just a matter of getting a panel and slapping it up. There's are technical aspects that need to be followed and if you don't know them, I would advise against doing it yourself. Study up on it and see if it's something you want to tackle on your own before you go too far doing legwork to find out details that might be cost prohibitive or too complicated. Good luck.

- Q:What, if any, improvement in efficiency per square foot or meter is realized by a solar panel in space vs. being mounted on the ground where the light is attenuated by the atmosphere?In passing, I found a site that gives an output of .89 watts / 4 in. sq for a particular home-mounted panel.

- The mirrors might could desire to be on computerized monitoring gadgets so as that using fact the sunlight strikes it might keep the pondered sunlight on the panel with value of optical sensors and stepper automobiles and %s or laptop controllers then you definitely've the mirrors which destroy in hailstorms except you employ chrome metallic ones that in the process basic terms mirror 60% in assessment to 80% for glass To tutor what I say take a small hand mirror outdoors and prop it up so it reflects at one brick or spot on wall mark it or keep in mind it then wait or come lower back in 20 min see what proportion times it may be moved and how complicated the development of circulate

- Q:How do solar panels affect the local job market?

- Solar panels can have a positive impact on the local job market. Their installation and maintenance can create new employment opportunities in the renewable energy sector, leading to job growth. Additionally, the development of solar farms and manufacturing facilities can attract investments and create more jobs in the local economy.

- Q:What do I need to use this as a battery charger

- I hope this will help you choose your charge controller / battery charger more effectively. Good luck!

- Q:Is it good? ( solar energy)

- How image voltaic Cells artwork through Scott Aldous interior this text a million. advent to How image voltaic Cells artwork 2. Photovoltaic Cells: changing Photons to Electrons 3. How Silicon Makes a image voltaic cellular 4. Anatomy of a image voltaic cellular 5. means Loss in a image voltaic cellular 6. image voltaic-powering a house 7. fixing image voltaic-means subject concerns 8. image voltaic-means experts and Cons 9. so lots extra counsel 0. See all actual technological know-how articles you have in all threat seen calculators that have image voltaic cells -- calculators that for the time of no way choose batteries, and on occasion do not even have an off button. as long as you have sufficient mild, they seem to artwork continuously. you're transforming into seen extra beneficial image voltaic panels -- on emergency highway signs and indicators or call bins, on buoys, even in parking lots to means lights fixtures. even if those extra beneficial panels are not so straight forward as image voltaic powered calculators, they're obtainable, and not that problematical to become attentive to in case you recognize the place to look. There are image voltaic cellular arrays on satellites, the place they're used to means the electric powered systems. you have in all threat additionally been listening to on the subject of the image voltaic revolution for the final 20 years -- the theory that sooner or later we are able to all use unfastened electricity from the solar. this could be a seductive promise: On a stunning, sunny day, the solar shines approximately a million,000 watts of means in line with sq. meter of the planet's floor, and if we could desire to deliver at the same time all of that means we could desire to truly means our residences and places of work for unfastened.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double Glass Mono(Poly) Crystalline silicon Solar Panel Model CR090M-B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords