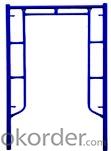

Door-H Frame Scaffolding with Hot Dip Galv

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of H Frame ScaffoldingDescription

As a high quality range of Scaffolding Frames-Standard H Frame is being offered to the clients in different specifications. These products have rigid welded frame of horizontal and vertical pipes. Further, these pipes are interconnected by scissor type cross bracings by the help of pins and spring clips.

Packaging & Delivery

Packaging Detail: | Frame system scaffolding package in the container, or according to your requested |

Delivery Detail: | after deposit 10-15 days |

2. Main Features of Frame Scaffolding

1) Frame system scaffolding is light duty, easy to erect and walk through, wide appciations for both inside and outside constructions.

2)A complete set of frame system scaffolding usually include 2 pcs of H frames ,2 pairs of cross braces and 4 pcs of joint pins.

3) Frame system scaffolding is for inside concrete supporting which can be used with the U Jack to supporting the concrete slab.

3.Frame Scaffolding product pictures:

5.FAQ

Presented like a shape of door,Frame-connected Scaffolding includes main frame,horizontal frame,cross brace,stage board and adjustable base. In order to display frame with coupler system enough,good performance of stability,firm structure of the whole,easy and fast to assemble and dismantle without any tools,safe working at height especially, and it is ideal material for construction engineering.

We have organized several common questions for our clients,may help you sincerely:

1)How about your company?

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, Our formwork and scaffolding are largely used in both domestic and all over world; We has over 10 year experience in scaffolding industry.

- Q:What are the safety requirements for the dismantling of construction scaffolding

- (5) remove the material, structural parts, etc., it is strictly prohibited to throw down, the use of rope tied firmly slow down, or with a crane, basket and other means of transport to the ground.(6) the scaffolding removed, should make clear the workplace after work, all materials and components should be neatly stacked, safe and stable, and timely transport.

- Q:Specification and type of scaffold erection

- technical requirementThe materials used for steel pipe scaffold shall meet the following requirements:1 steel pipe diameter should be 48 ~ 51mm, wall thickness of ~ 3.5mm, length of 2.1 ~ 2.8m and 4 ~ 6.5m is appropriate, there are serious corrosion, bending, cracks, damage shall not be used.

- Q:What does my earth science teacher mean when he says to do a powerpoint with Link Scaffolding,how d u do it?

- Link Scaffolding = A search found no answer. - Ask teacher to clarify.

- Q:So, 12 Days Ago I Went To Blue Banana To Get Scaffolding On My Right Ear. Everything Went Fine And They Did A Brilliant Job. I Clean It With Sea Salt Soaks 2-3 Times A Day And Use A Bit Of Tea Tree Oil After To Help Sooth. I Was Just Wondering From People Who've Experienced This Piercing How Long It Took For Yours To Stop Hurting And The Time It Took For The Swelling To Go Down (: Thank You lt;3

- It only really hurt for the first month-ish but was really tender for the first 3 months. After that, I barely noticed it was there. Goodluck :]

- Q:Standard Specification for bowl buckle scaffold

- A new type of scaffold developed in China

- Q:Which accessories are included in a movable scaffold

- (1) single specification steel pipe scaffold. It only uses a steel pipe specifications, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.(2) scaffold with various specifications of steel pipe. The utility model is composed of two or more steel pipes of different specifications, such as a door type scaffold.(3) steel scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on.

- Q:The basic form of external scaffolding

- The bowl buckle steel tube scaffold is composed of steel pipe pole, cross bar, bowl buckle joint and so on. The basic structure and erection requirements and fastener type steel pipe scaffolding similar, the main difference lies in the bowl buckle joint.The bowl buckle joint is the core component of the scaffold system, which consists of the upper bowl buckle, the lower bowl buckle, the cross bar joint and the limit pin on the upper bowl buckle.

- Q:What's an antonym for the word scaffold?

- I don't think there is one. 'Scaffold' is a noun but, with the exception of gender nouns (egs boy/girl; man/woman) it's verbs, adjectives, adverbs and prepositions that can have true opposites.

- Q:Should the WWE put John Cena in a triple threat thumbtack scaffold cage of death with New Jack & Necro Butcher?

- i sharted. PS: please purchase my new toilet hawaii chair

- Q:Im thinking of getting a scaffold piercing when i am old enough to and ive seen videos of people who have one but it cause bacteria in their ear and if they take it out their ears swell. I want to know if this is a bad piercing to get. Also i have had an allergic reaction to an earring before and im not sure what type of earring it was. Can that affect it as well.

- Getting piercings is not that dangerous except that a lot of normal people will think that you are a weirdo

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Door-H Frame Scaffolding with Hot Dip Galv

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords