DN125 Hardened Pipe of Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN125 Hardened Pipe of Schwing Concrete Pump

1. Structure of DN125 Hardened Pipe of Schwing Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of DN125 Hardened Pipe of Schwing Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

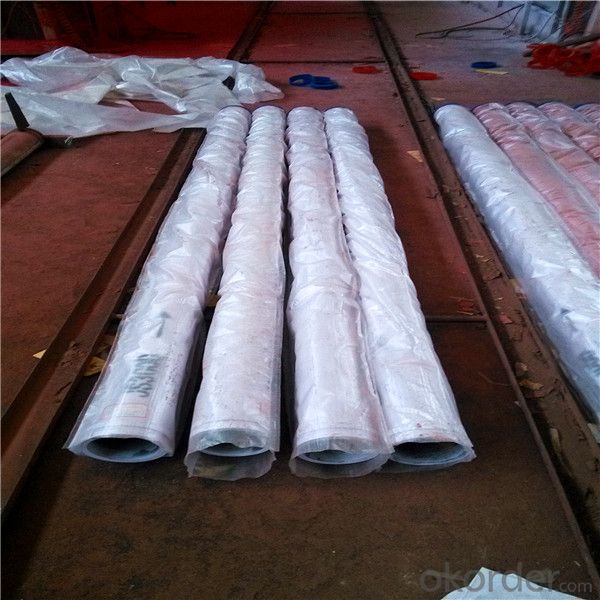

3. DN125 Hardened Pipe of Schwing Concrete Pump Images:

4. DN125 Hardened Pipe of Schwing Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

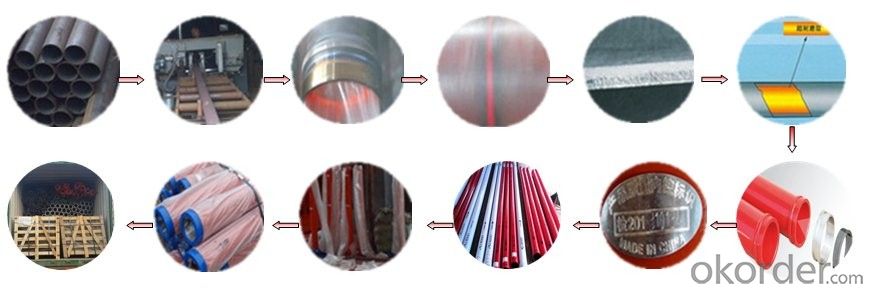

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:Can I get spare parts for both concrete pumps with and without boom stabilizers?

- Yes, you can get spare parts for both concrete pumps with and without boom stabilizers.

- Q:How often should hydraulic pumps be inspected or replaced in a concrete pump?

- Hydraulic pumps in a concrete pump should be inspected regularly to ensure their proper functioning and prevent any potential issues. The frequency of inspections depends on various factors such as the intensity of use, operating conditions, and manufacturer's recommendations. Generally, it is recommended to inspect hydraulic pumps in a concrete pump every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, if the pump is being used in harsh or demanding conditions, more frequent inspections may be necessary. Replacement of hydraulic pumps should be based on their condition and the recommendations of the manufacturer. If the pump shows signs of significant wear and tear, leaks, reduced performance, or any other issues that cannot be resolved through maintenance or repair, it may be necessary to replace the hydraulic pump to ensure the safe and efficient operation of the concrete pump.

- Q:Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can be retrofitted to older pump models. However, it is essential to ensure compatibility and proper installation to guarantee optimal performance and safety. Professional advice and support should be sought to ensure correct retrofitting of spare parts to older pump models.

- Q:What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts include cracks or fractures in the components, corrosion or rust on metal parts, excessive vibration or noise during operation, decreased performance or efficiency, and visible signs of wear on seals or gaskets.

- Q:How often should a concrete pump spectacle plate be replaced?

- The frequency of replacing a concrete pump spectacle plate depends on various factors such as usage intensity, maintenance practices, and the condition of the plate. However, as a general guideline, it is recommended to inspect and potentially replace the spectacle plate every 500 to 1000 hours of operation or sooner if signs of wear or damage are observed. Regular inspections and timely replacements help ensure optimal performance and prevent any potential safety risks.

- Q:How do I identify the specific spare parts I need for my concrete pump?

- To identify the specific spare parts you need for your concrete pump, you can follow these steps: 1. Consult the user manual: Start by referring to the user manual provided by the manufacturer. It typically contains a detailed parts list along with part numbers and descriptions. The manual may also include diagrams or illustrations to help you identify the required spare parts. 2. Contact the manufacturer: Reach out to the manufacturer of your concrete pump. They will have the most accurate and up-to-date information about the spare parts for your specific model. Provide them with the model number and any other relevant details to ensure accurate identification of the required parts. 3. Engage with authorized dealers or distributors: If the manufacturer is unable to directly provide you with the spare parts, they can often refer you to authorized dealers or distributors. These professionals specialize in concrete pump parts and can help you identify the specific spare parts you need. Share the model number and any other relevant details to assist them in finding the correct parts. 4. Take pictures or measurements: If you are unable to find the required information through the manual, manufacturer, or authorized dealers, you can take pictures or measurements of the damaged or worn-out parts. This will help in visually identifying the parts and providing accurate dimensions, which can be shared with suppliers or experts in the field who may be able to assist you further. 5. Online research: Utilize online resources such as parts catalogs, forums, or websites dedicated to concrete pump spare parts. These platforms often have extensive databases and knowledgeable communities that can help you identify the specific spare parts you need. Search for your concrete pump model and explore the available resources to find the relevant parts. Remember to prioritize quality and authenticity while purchasing spare parts for your concrete pump. It is essential to buy from reputable sources to ensure the durability and longevity of your equipment.

- Q:What is the function of a concrete pump control box?

- The function of a concrete pump control box is to control and regulate the operation of a concrete pump, including starting and stopping the pump, adjusting the flow rate and pressure of the concrete, and monitoring various parameters such as engine speed and hydraulic pressure. It provides a centralized control system for efficient and safe operation of the concrete pump.

- Q:Are there any specific guidelines for the disposal of old or damaged concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of old or damaged concrete pump spare parts. It is recommended to contact local waste management authorities or recycling facilities to inquire about proper disposal methods. In many cases, recycling concrete pump spare parts is encouraged to reduce environmental impact.

- Q:How often should a hopper filter be cleaned or replaced?

- A hopper filter should ideally be cleaned or replaced every 3 to 6 months, depending on the usage and the level of contamination.

- Q:How often should hopper agitator motors be inspected or replaced in a concrete pump?

- Hopper agitator motors in a concrete pump should be inspected regularly, ideally during routine maintenance checks, to ensure they are functioning properly. Depending on the usage and condition of the motor, it may need to be replaced if it shows signs of wear, damage, or malfunctions. Ultimately, the frequency of inspection and replacement will vary based on the specific concrete pump and its usage patterns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DN125 Hardened Pipe of Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords