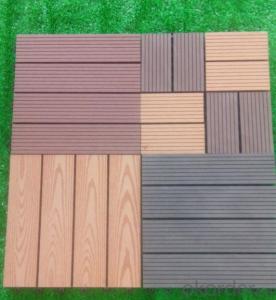

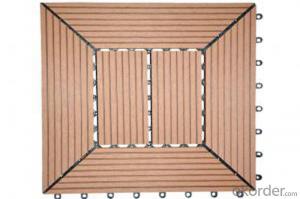

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY WPC Interlocking Composite Decking Tiles:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of DIY WPC Interlocking Composite Decking Tiles:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY WPC Interlocking Composite Decking Tiles:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of DIY WPC Interlocking Composite Decking Tiles:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY WPC Interlocking Composite Decking Tiles:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q:Classroom platform shop plastic floor with no need to do self leveling?

- For example: the stadium used (table tennis, gym, badminton, basketball), shopping malls, dance, stage, KTV, hotel, hospital, hotel, operation room, family, kindergarten, School

- Q:What plastic floor

- Worry。 Its characteristics are stone, tiles and other incomparable.

- Q:There is a little water with plastic sheeting can pave the floor?

- Keep the ground dryThe floor needs to cement ground water in clean out before installation, otherwise it will produce a certain tidal wave, easily lead to the floor cracks, caused after the installation of the warped floor, so the floor before the cement ground moisture in row of clean, to ensure that the ground is dry.

- Q:Plastic floor coil and sheet are what size

- The floor sheet is more soft texture of the rolls of the floor, the width is 1.5 meters, 1.83 meters, 2 meters, 3 meters, 4 meters, 5 meters, the length of each volume is 7.5 meters, 15 meters, 20 meters, 25 meters, the total thickness of 1.6mm-3.2mm (only commercial floor. (champion) sports flooring thickness of up to 4mm, 5mm, 6mm etc.).

- Q:How many yuan per square meter of plastic floor

- Customer: why is your price so cheap? Shanghai and the United States to answer: factory direct sales! 3, the customer asked: your home a few years ago? Shanghai, Shanghai and the United States replied: plastic floor 50 yuan per square shelf life of 6 years, the price of $180 per square shelf for 15 years! Please understand Shanghai Hu Mei plastic floor for the sports ground facilities, good floor to prevent injuries, foot comfort

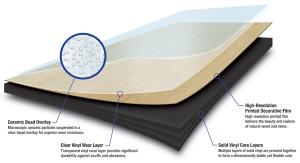

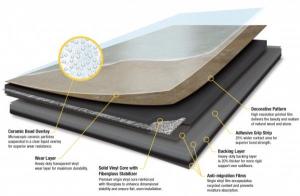

- Q:What is the material of the plastic foam plate

- Soft PVC sheet flooring material is relatively soft, has certain elasticity, comfortable, but the surface temperature performance is poor. Two, foam printing plastic floor

- Q:Badminton plastic floor? Want to be a sports venue, which plastic sports floor brand is better

- Badminton plastic floor is now used in indoor venues this1 at present, the major venues for badminton venues are designated laying plastic floor2 plastic floor and solid wood floor compared to: light weight, good elasticity, friction and other advantages3.KEMP champion badminton plastic floor is good, you can look at

- Q:How much is a square floor of plastic floor?

- Durability: the product of raw materials for polypropylene (PP) for high strength materials, added with anti ultraviolet radiation, anti oxidant, cold resistant materials such as modified polypropylene, the advantages of the products with pressure, impact resistance, high temperature, long service life etc.. High weather resistance, high temperature, humidity, rain is not afraid of the sun, never warping deformation beneath the bitter snows. There is no climate zone restrictions, no water after the site

- Q:What is the role of badminton PVC plastic floor

- The role of badminton PVC plastic floor is as follows:1, is composed of PVC wear-resistant layer, glass fiber reinforced layer and PVC foam buffer layer composition.2, anti aging and fastening technology, wear resistance, the service life of up to 15 years.

- Q:Basketball court assembled plastic floor why pack

- The main thing is that you choose the floor quality is not good. Do not choose the floor of Hebei, Zhejiang, the use of PP material is too bad, you can consider the manufacturers in Guangzhou: love fantastic speed lattice 02, CELINE Seg, Yin Chi sports Bert, Rio sports LT

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIY WPC Interlocking Composite Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords