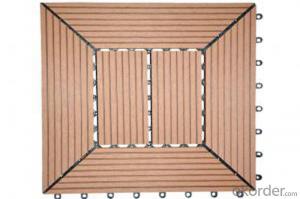

DIY WPC Decking Mosaic Floor Flooring Joint

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY WPC Decking Mosaic Floor:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of DIY WPC Decking Mosaic Floor:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY WPC Decking Mosaic Floor:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

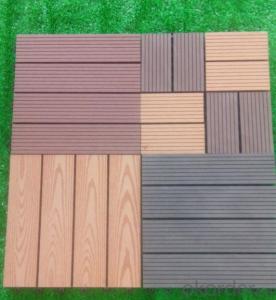

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of DIY WPC Decking Mosaic Floor:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY WPC Decking Mosaic Floor:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q:Plastic floor glue how shop, suitable for use at home

- Construction (general) 10 per square meter, packaging materials of $40 per square meter, (Professional) construction of 13 yuan per square meter,

- Q:How to clean plastic floor

- Specific methods of operation are: 1, the first floor of the cleaning of the plastic floor to dilute the good cleaning fluid into the washing machine, the boot operation, from the back to the front, according to the straight line, so you can avoid missing.

- Q:Warm the house, with plastic floor?

- Warm the house, with plastic floor?Sky0384 | browse 928Posted on 2014-08-14 16:34 best answerNo problem with heating, the premise is to buy a good quality brand plastic floor. Such as the LG floor, my home for two years, I feel good, than the wooden floor, like when dealers, abrasion resistance, stain resistance, anti slip, sound insulation, heat conduction, fast walking, feel comfortable, beautiful color texture mosaic diversity without fracture, dimensional stability and construction of heat and moisture are not deformation, environmental protection I think all the advantages of formaldehyde free experience. There are five people in my family, there are elderly people have children, with the ground heating.

- Q:Can I have a white mat?

- Wood flooring, acceptance and use of standard requirements, in the mat below paving a layer of plastic film, seam overlapping 20mm, and tape seal, in the geothermal conditions, even if the tape is moisture degumming, it is difficult to influence the floor, can more effectively prevent the harm of moisture on the floor. Therefore, it is necessary to lay plastic film in the geothermal environment.

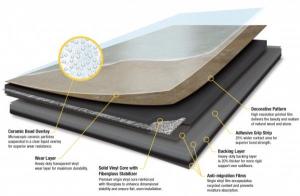

- Q:Board PVC plastic floor plastic toxic

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

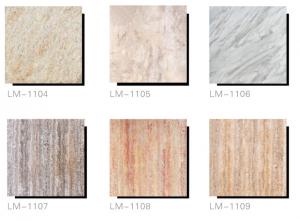

- Q:How to tear off the plastic film on the floor tiles

- Your turn is above if the plastic film may be the glass ceramics, finished directly to tear it, but to pay attention to, if it is microcrystalline stone, the surface of the glass is not scratch, when used to pay attention to, iron furniture must be wrapped, lest scratch, once scratch, there is no way to fix.

- Q:How to deal with the plastic foam on the floor?

- After that, to maintain a season or half a year on it. Do not use solid wax unless the floor has been badly worn. General solid wax suitable for more than five years of solid wood flooring, but once is enough, usually the use of wood oil. Strengthen the wood floor maintenance rules and cleaning methods to strengthen the maintenance of the wood floor is relatively simple, usually only need to do a half dry mop wipe, try to avoid moisture and too sharp, too hot items on the floor damage

- Q:What is the price per square metre of plastic floor?

- And the price of this plastic floor in accordance with the use of different location, the difference between the laying of a slightly larger, then there will be some differences in prices. This is a common phenomenon.

- Q:Can the plastic stair step of the cement in the home spread the plastic floor

- Need to do cement self leveling. If the surface is flat, can be installed directly

- Q:EVA plastic floor and PVC plastic floor which is good

- EVA: is elastic, flexible, shiny, breathable and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIY WPC Decking Mosaic Floor Flooring Joint

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords