direct factory for carbon fiber tube 22mm,19mm,18mm,16mm,14mm,13mm,11mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon fiber tube,carbon fiber bar,CFRP tube

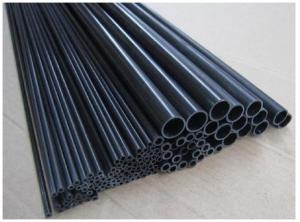

Carbon fiber tube description : Pulwell has designed and produced carbon tubes especially for new generation tripods. Our carbon tubes use an exclusive process based on pull winding of long carbon fibers, which are precisely wrapped and combined under high pressure and temperature with epoxy resin to a 1.2-1.5mm wall thickness. This manufacturing process ensures stiff, light tubes resistant to bending, has good tensile and compression strength, a high degree of stability in extreme temperatures, absorbs vibration

and withstands fatigue better than other carbon fiber tube processes.

Carbon Fiber Tube Features:

1) High strength

2) Lightweight but strong, 30% lighter than equivalent alloy version without compromise on strength, torsional stability or durability

3) Amazing and unique carbon finish

4) Carbon/fiberglass hybrid products and different finishes are available

Carbon Fiber Tube Photo:

When not in contact with air and oxidant, the carbon fiber can tolerate more than 3000 degrees high temperature, has outstanding thermal resistance, compared with other materials, carbon fiber temperature is higher than 150 DEG C strength began to decline, and the higher the temperature, fiber strength more.

Carbon fiber tube, also known as the carbon fiber tube, also known as carbon nanotubes, carbon tube is using carbon fiber composite pre immersion in benzene vinyl polyester resin by heating curing pultrusion, winding deflection) and. Through different mold production a variety of profiles can be in the process, such as: carbon fiber with different specifications of round pipe, square tubes of different specifications, different specifications of the sheet, and other sections: in the production process can also package 3K to beautify the surface packing and so on.

Characteristics of carbon fiber tube

1, tensile strength: the strength of carbon fiber is 6-12 times of steel, can reach 3000mpa above.

2, the density is small, the weight is light. Density only steel 1/4 less than.

Two, physical and chemical properties and uses

Carbon fiber tube with high strength, long service life, corrosion resistance, advantages of light weight, low density, widely used in kites, model aircraft, a lamp bracket, PC equipment rotating shaft, etching machine, medical equipment, sports equipment etc. machinery and equipment. Dimensional stability, electrical conductivity, thermal conductivity, thermal expansion coefficient of small, self lubrication and energy absorption can be a series of excellent performance. With high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance, etc..

The disadvantage is that it has a conductive (cm--1.5 x 10-3), the advantage is that there is a very good tensile strength (such as the number of filaments to 12000 units of the calculation, the tensile strength of kg/mm2--400).

For carbon fiber pipe production of carbon fiber content, directly determine the performance and value of its mechanical properties. The carbon fiber tube has the characteristics of light weight, high strength and high tensile strength, but special attention should be paid to the use of the carbon fiber tube.

- Q:Do you have DN150-DN80 variable diameter steel pipe joint?

- GB-T12459-2005 seamless butt welded steel pipe, with all the data in it.

- Q:my smoke detector keeps beeping and its so fcuking annoying!!!its not set-up by batteries (by wires)its not old but not brand newi cant buy a new one we live in a apartment and its 4:30 in the morning!!theres no smoke or fire or anything like that!! (and no heat from the shower or sumthing either)i have no idea what to do its annoying and it wont stop!! its been going off for almost 2 hours!i dont think the workers can come out because like i said its 4:30 in the morningwhy the hell is it doing this!!? and how can i stop it!!? thank u so much! (;(dont tell me to wait and get a new one because we cant even get the new one our apartment owners have to do all of that stuff) thanks

- When you Say low pressure is it pressure or vacuum? What kind of system is it? It could be the shutoff valve is not completely sealing (IE a glob of glue where the valve seats) or other factors such as a valve packing leaking is possible, If it is a pressurized system you could make a soap solution and check your glue joints to see if they bubble or if it is possible to cap and drain the system you can fill it with water and then check for leaks. Good luck and update your ?? to clarify

- Q:Phoney Tony used to love posing with factory workers wearing the fluorescent vest, hairnet, safety goggles etc. What a class act he was!

- Punish her, Every time she swears she looses a toy or treat, Whatever you do. No 5yo should even know bad words, Let alone say them to her parents.

- Q:What safety equipment do you have at home for science experiments? What safety equipment should you have at home to conduct science experiments? How can you protect yourself while experimenting in science? How does OSHA protect you at your workplace?

- yes it can but you have to purchase the premium version it provides with all kind of security

- Q:My landlord has continued to not fix problems in the house we are living in. There is sewage water in my basement no locks, no heat, no smoke detectors, the floor is leaking into the basement and yet they want there money. Are they eligible to get the past rent due from us even though the house should be condemned until these issues are fixed I mean it is serious health concerns to my two small children?

- The only reason to change pushrod length is when you change the deck height, mill heads or change the base circle of the cam. The base circle change would require longer pushrods, the other 2 require shorter.

- Q:I am going to construct out of wood, an exact model of the concrete pier caps I will use to top some brick columns I am constructing (as I replace old chain link fencing). I want to make a precast mold of this wooden model so that I can use mold to duplicate/ pour the concrete pier caps.What kind of resin material do I need to create a mold of the wooden model? It would be ideal if the mold would be slick and shiny, so the cured concrete can easily come loose from the mold. I have to use the mold 10 times.Do I need liquid fiberglass or hot plastic or what? I've never done anything like this before, so I am clueless.Here is a link to the type of pier cap I will first build out of wood. See pier cap 1:

- Why don't you just call Lowe's, Home Depot, or your local hardware store and ask. I'm sure the prices vary depending on the diameter of it.

- Q:why did my mom put a smoke detector in my room!?

- Been a plumber over 40 years. What you have now is pure junk. You will surely be removing sheetrock.Type L hard copper would be a permanent and sure way to a trouble free system however being from the old school I have no faith in shark bites being buried in a wall. The only sure way is to sweat it together. It takes more time, but is well worth it. The only reason these new fangled ways of joining pipe and fittings, is because not many people can sweat copper any more. If this job is put in right you probably won't need a regulator unless your your pressure is off the map. Hope this helps.

- Q:Type parameter of pipe joint

- 600.50 9/16 0.09 7/16 1.14 3/16 1/8 SS-MC-TF3-NT2 1.23 0.38 0.63 0.54 0.12 7/16 1/2 0.97 3/16* 1/4 SS-MC-TF3-NT4 1.43 0.56 0.63 0.54 0.12 9/16 1/2 1.17 1/4 1/8 SS-MC-TF4-NT2 1.29 0.38 0.70 0.60 0.19 1/2 9/16 1 1/4 1/4 SS-MC-TF4-NT4 1.49 0.56 0.70 0.60 0.19 9/16 9/16 1.20 1/4 3/8 SS-MC-TF4-NT6 1.51 0.56 0.70 0.60 0.19 11/16 9/16 1.22 1/4 1/2 SS-MC-TF4-NT8 1.76 0.75 0.70 0.60 0.19 7/8 9/16 1.47 5/16*

- Q:A friend of mine gave me a used Mac Pro he found. Everything works fine except it has one of those annoying cable locks clamped on the back. He said he took bolt cutters to the cable to try and shorten it, but the lock part and a few inches of cable remain. I tried pulling on it and twisting it, but nothing works. I can't see a brand name on it, but its a combination type.

- Co2 is carbon dioxide,which puts out most fires which do not have their own oxygen supply. and since it is a gas and not liquid it is safe for electrical. I would just be careful for liquid fuel since the force of the gas coming out can spread the liquid. IE a chip pan fire, with hot oil spraying you can be injured or spread the fire if not thinking, as in turning off the heat source. but the best in a car or home, a as long as you remember that also you need oxygen as well as the fire, so tackle and get out fast before you collapse, leave the real fires to the fire brigade. you endanger yours and their life's. If you are still not sure ask your local fire station they will help you understand

- Q:what should you do if the fire extinguisher gets in your face and skin?

- Ever hear of bucket loading It is similar to bailing out a boat only in reverse. The people you rent from will allow you to hire a plumber so long as you pay for all the work. It is a benefit to the landlord. But do not expect to get a cut in your rent. Your only other solution is finding rubber hose that fits over the tap faucets in the bathroom and that you can tighten into position with a hose clamps 4 or 5) and mickey mouse something together that way. Or ask the landlord if they have a washer connect somewhere else that you can connect to. They only can say Yea or Nay

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

direct factory for carbon fiber tube 22mm,19mm,18mm,16mm,14mm,13mm,11mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords