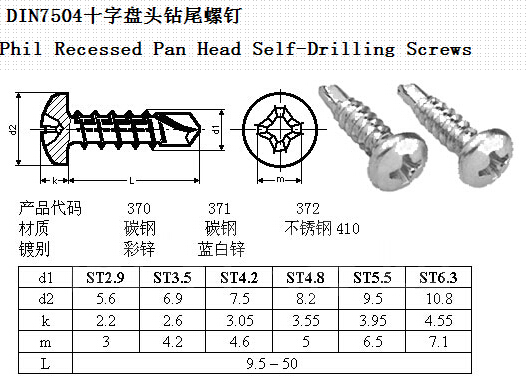

DIN7504 Phil Recessed Pan head Self-Drilling Tapping Screws

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Name | DIN7504 Phil Recessed pan head Self-drilling Tapping Screws |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | 8#-18*13 ~ 14#-14*125 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

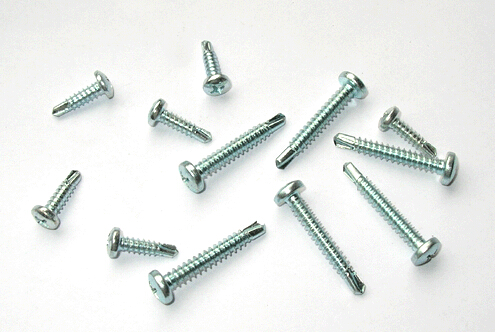

Product Picture:

- Q:In the fastener industry, 1018 refers to what material

- 1018 is the United States material, you can use domestic steel instead. Processing, do, use, distribution of US bolts and nuts, US bolts and nuts, American standard bolts and nuts, must have the US screw standard. You should buy a set of the latest US fastener standards Daisy "IFI English Fastener Standard Handbook, eighth edition) (published in English) (published in 2011), experts are the winner, have the standard will have the relevant business.

- Q:I'm talking about another thing

- crews for the daily life of indispensable industrial necessities: such as cameras, glasses, watches, electronics and other small screws used; television, electrical products, musical instruments, furniture and other general screws; as works, construction, bridges are large Screws, nuts; transport equipment, aircraft, trams, cars, etc. are the size of the screw and use. Screws have an important task in industry, and as long as there is industry on earth, the function of screws is always important. Screw is thousands of years of people in the production of common inventions, according to the application field, it is the first major inventions of mankind.

- Q:Screw hole slip wire how to do?

- Can be in the original screw hole at the larger screw hole to cover the original screw hole, the most good new hole diameter is greater than the original hole diameter; 2. If the original thread hole has no space, then just change to other places to re- drilling

- Q:Who include who btween them?

- Fasteners are said from the point of view of the action, which contains both standard parts (GB ANSI ASME DIN EU JIS, etc.) and non-standard parts (according to the drawings) is not entirely a concept

- Q:What is the role of flat washers? There is a friend who can introduce

- Flat washer is generally used in the connecting piece is a soft texture, a hard brittle, its main role is to increase the contact area, pressure distribution, to prevent the soft texture of the crush.2 parts between the connecting piece and the nut. A flat metal ring is generally used to protect the surface of the connecting piece from the nut.3 flat pad is to increase the contact area, and to prevent the bolt and workpiece friction;The main function of the 4 flat washer is to protect the surface of the connector, to prevent the bolt nut tightening when the workpiece surface

- Q:In the design, the bolt connection is necessary to have a gasket?

- Bolted components can not be avoided by extrusion, and a flat gasket reduces the wear of the surface of the component when tightening the bolts, especially those of the aluminum material. In parts when the bolt is tightened by extrusion deformation or broken, the torque control is improper. In the mobile phone production line, a lot of workers to install mobile phones, some people do not tighten tight, some people will break the crack parts, so the production line are used to play the role of measuring torque wrench.

- Q:Engineering argument, usually referred to as the M3 screw, M refers to what is the meaning? The Please instruct the engineering staff.

- International Metric Thread System: The national standard CNS adopts the thread. The crest is flat and easy to be turned. The tooth bottom is rounded to increase the thread strength. The thread angle is 60 degrees. The specification is expressed by M Metric thread can be divided into two kinds of coarse and fine teeth, such as M8x1.25 (M: code: 8: nominal diameter .1.25: pitch).

- Q:Please understand the friends of the self-tapping nails, screws, nuts production process, is the manufacturer's process. The more specific the more detailed the better

- This is very simple, the screw wire is generally based on the size of the screw into the back, and then according to the order processing, starting - rubbing teeth - plating - packaging on the success

- Q:Gasket 300HV relative to what material?

- For the 100HV level can choose ST12, ST13 and Q235, Q215, Q195, etc., the surface hardness can reach about 110HV

- Q:I would like to look at my mp4 apart, the above screws are small, is cross-type, our family is not so small screwdriver, what can be used to screw the screw Oh, a little practical method Kazakhstan,

- Is there a special small screwdriver that is special, if it is not used to cause or nails sometimes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIN7504 Phil Recessed Pan head Self-Drilling Tapping Screws

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords