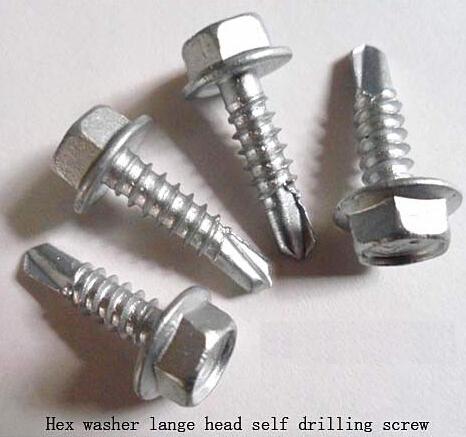

DIN7504 Hex Washer Lange Head Self Drilling Screw

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Name | DIN7504 Hex Washer Lange Head Self Drilling Screw |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | 8#-18*13 ~ 14#-14*125 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q:The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- The easiest way to change the place to hang the original place to hang a mural

- Q:A194 GR3 is what style fasteners

- A194 American standard I know is the US system, but now do not understand is GR3 in the end is what it means

- Q:When do flat washers use GB95 when using GB97.1?

- There is no difference in the application. See the tolerance, the high requirements of the use of GB97.1. in order to save money, and the application environment is not high, use GB95

- Q:Want to fix something, which is a triple iron (do not know how thick), would like to ask what screws can be turned into? Can ordinary drill go in? The question is to consider the drill or consider the screw, or have to consider? Thank you! The

- Self-tapping screw; is a screw with a drill bit, through a dedicated power tool construction, drilling, tapping, fixed, locked once. Self-tapping screws are mainly used for the connection and fixing of some thin plate pieces, such as the connection of color steel plate and color steel plate, the connection of color steel plate and purlins, wall beam, etc., its penetrating power is generally not more than 6mm, the maximum does not exceed 12mm.

- Q:How to remove mildew on the rubber washer

- Solution:1, activated carbon with gauze wrapped and then put;2, orange or orange peel or lemon cut into small pieces, put into steam for a while;3, is not in line with the onion steamed but the effect is poor.

- Q:Who is the information on fasteners ah?

- Fastener materials (steel wire, stainless steel wire) Fasteners use tools, fastening systems.

- Q:What are some of the common fastener products?

- The washer is a flat, rounded fastener that is typically mounted between bolts, screws, or between the support surface of the nut and the surface of the connecting part to increase the contact area of the connected part and reduce the pressure in a certain area , To ensure that the connection parts will not be damaged; there is a flexible washer, but also to prevent the nut loose situation.

- Q:Stud that head or nut that ah, I need to have the authority of the provisions of the document, please know that the prawns are told, thanks to!

- The main purpose of the elastic cushion is to prevent loosening, which is added at the end of the screw, and the screw nut is arranged on the side of the nut.

- Q:Fasteners often say that the nature of galvanized oxidation is what it means

- Fasteners, is a fastening connection with the application of a very wide range of mechanical parts. Fasting, widely used in industries such as energy, electronics, electrical appliances, machinery, chemical, metallurgy, mold, hydraulic, etc., in various machinery, equipment, vehicles, ships, railways, bridges, construction, structure, tools , Chemical, instrumentation and supplies, etc., can see a wide range of fasteners, is the most widely used mechanical base pieces. It is characterized by a wide variety of specifications, performance purposes vary, and standardization, serialization, the degree of generalization is also very high. Therefore, some people have a national standard of a class of fasteners called standard fasteners, or simply referred to as standard parts.

- Q:What's the meaning of the "200HV" of the gasket material? Is that the hardness level? What materials are usually chosen? Know predecessors please advice, younger brother is not very grateful!!!

- Should be less than 200HV, which is gasket, should consider the tightness, high hardness of the seal is not good!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIN7504 Hex Washer Lange Head Self Drilling Screw

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products