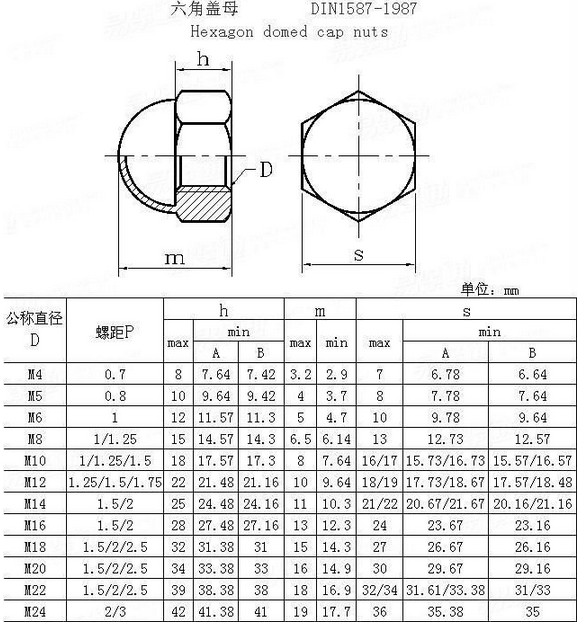

DIN1587 Cap Nut M3-M24

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

Product Name | DIN1587 Cap Nut M3-M24 |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M3--M24 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q:How is the screw nailed to the wall

- Use a hammer to make a hole in the wall, and then plug a plastic expansion tube, the last screw.

- Q:Bolts and other connection fasteners some points A B C grade what it means

- Bolts and other fasteners connected due to a wide range of applications, the product level requirements are different, so the bolt product grade is divided into A, B, C three grades. One of the most accurate A, C level of the most inaccurate, B between the two. Class A is used for important applications where assembly accuracy is high and subject to greater impact, vibration or variable loads. Class A for d = 1.6-24mm and l ≤ 10d or l ≤ 150mm bolts. B grade for d> 24mm or l> 10d or l ≥ 150mm bolts, thin rod B grade M3-M20 hexagonal flange bolts, anti-loose performance better. Class C is between M5 and M64.

- Q:M4.8 * 25 What does it mean in screw size?

- No meaning that there is no one of the most close to the national standard is, M5 * 25 For example, GB70.1, M5 × 25 hexagon socket head cap screws

- Q:How to look at screw models

- According to the size of the outer diameter, such as the outer diameter of 6 mm, then the M6 screws. But not every millimeter has, according to a certain law.

- Q:A tightened screwdriver has been damaged, that is, the cross into a round mouth, and now I need to get it out for a new one, is there any way to take it out?

- First find a good tool ... tiger pliers ~ and the like ... and then forced it ... I was the last time so get ... good results ~ also exercise

- Q:What is a screw? What is a nail? What is the concept? What is the difference!

- Screws, screws luódīng, luósīdīng [Screw] Small cylindrical or conical metal rods with threaded parts, with a slotted or with a concave head, the use of machine nails alone? What machine nail Oh? How have I ever heard of it?

- Q:I would like to ask the car transmission inside the thrust washer (thrust washer) is used to do ah?

- Transmission in order to reduce the noise, the general design of gear teeth, which in the operation of radial force, thrust washer is to prevent excessive wear of the gear side!

- Q:How to remove the broken screw?

- The other are open to grow a little, grinding flat to seize the rotation, or the middle cut a knife with a zigzag tool to turn, the bigger the better to take the iron put on the surface of the welding, or with a word tool alignment loose Open the direction of the angle to play a few turn a few times, did not save the drill through the hole directly through the big mouth to re-open teeth on the line.

- Q:What is the difference between Chinese-made screws and US screws?

- Formal manufacturers of screws from the size of the model is no difference (except small factories or workshops), the difference is mainly from the manufacture of screws and materials used in the surface of the treatment process only. Say even the Chinese exports of screws, in terms of manufacturing is also in accordance with foreign standards or contract requirements (such as the use of foreign customers specific raw materials or technology), the cost is relatively high, not the domestic market sales. Reference it.

- Q:how to use Motor washer

- Spring washer loose, as well as sealing gasket, corrugated gasket clearance

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIN1587 Cap Nut M3-M24

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords