Diethylene Glycol Dibenzoate, DEDB, DOP Substitute

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

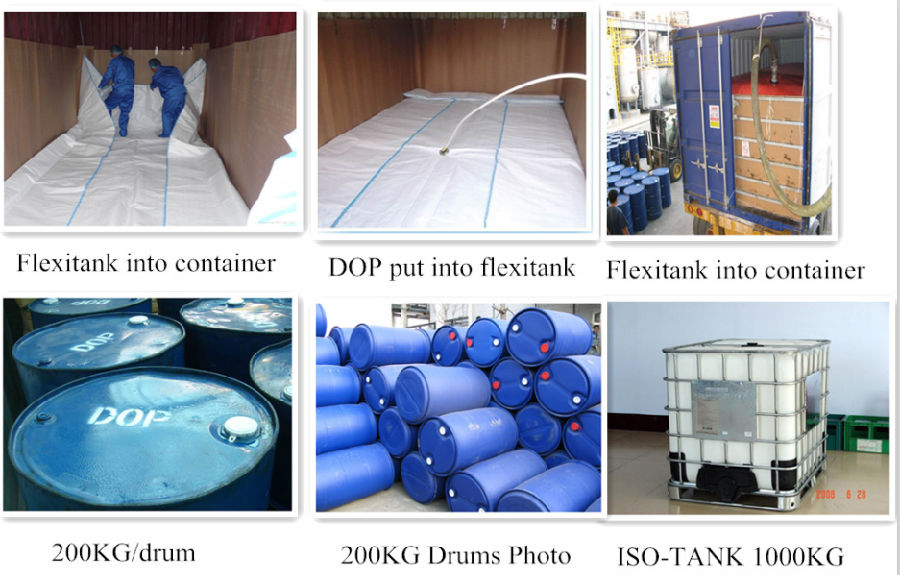

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q:What is positive and negative catalyst in chemistry?

- Positive catalyst can speed up the reaction rate, negative catalyst can slow down the reaction rate

- Q:Palladium is the main catalyst in chemistry?

- Palladium in the chemical mainly to do the catalyst; palladium and ruthenium, iridium, silver, gold, copper and other alloy, can improve the palladium resistivity, hardness and strength, used in the manufacture of precision resistors, jewelry and so on. While the most common and most commercially available palladium jewelery is palladium.

- Q:What is the difference between biological and chemical catalysts?

- catalysts which catalyze the chemical reactions taking place in human body such as enzymes are called bio-catalyst and other one's which are generally used in laboratory by chemists for multiple type of reactions are chemical ctalysts

- Q:High school knowledge __ teacher do not know right!

- Nothing to do, but with the percentage of activated molecules, is proportional to

- Q:In the chemical calculation, the quality of the catalyst should not be counted before and after the reaction

- It is not the same .. because the quality of the catalyst will not change .

- Q:Is the catalyst in the field of inorganic chemistry?

- In the chemical discipline, including inorganic chemistry, analytical chemistry, organic chemistry and physical chemistry and other secondary disciplines, catalytic science for the three disciplines, generally attributed to the physical chemistry of the mouth.

- Q:Please make it simple because I need it for school and please give to examples for the second part Thanx :D

- A catalyst is a substance that speeds up the rate of a chemical reaction with itself being chemically unchanged at the end of the reaction. They are useful as they help to lower the minimum amount of energy needed ( also known as activation energy) to start the reaction. Hence, by lowering the activation energy of the reaction, they help to speed up the rate of reaction. For example, in the Haber process for the manufacture of ammonia, the catalyst iron is added to speed up the rate of reaction between hydrogen gas and nitrogen gas. Otherwise, the reaction would have proceeded much more slowly. Another example is the catalyst nickel used in the manufacture of margarine and vanadium (V) oxide for manufacturing sulfuric acid. As catalyst remain chemically unchanged after a reaction, they can be reused again and hence, they are required in minute amounts. An example is the washing powder used in washing clothes, they help to remove food stains by digesting the proteins in food. They can be reused after each reaction and hence, you do not need to add in the whole packet of washing powder but only a few spoonful.

- Q:Does the catalyst slow down the chemical reaction rate? Still can only accelerate

- As far as I know, depending on the definition of the catalyst to reduce the activation energy can only accelerate the reaction rate. However, some substances can reduce the rate of reaction, for example, to dilute the reaction solution to slow down the reaction rate, but slow down the general mention of the catalyst.

- Q:Will the catalyst change in the chemical reaction?

- The role of catalyst refers to the chemical reaction in the catalytic role of the reagent, of course, the catalytic effect can be divided into two kinds, one is to speed up the progress of the reaction, one is to inhibit the progress of the reaction, the specific role of the catalyst to see the actual reaction needs.

- Q:The size of △ H in the thermochemical reaction equation is related to the use and unused catalyst

- It does not matter

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Diethylene Glycol Dibenzoate, DEDB, DOP Substitute

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords