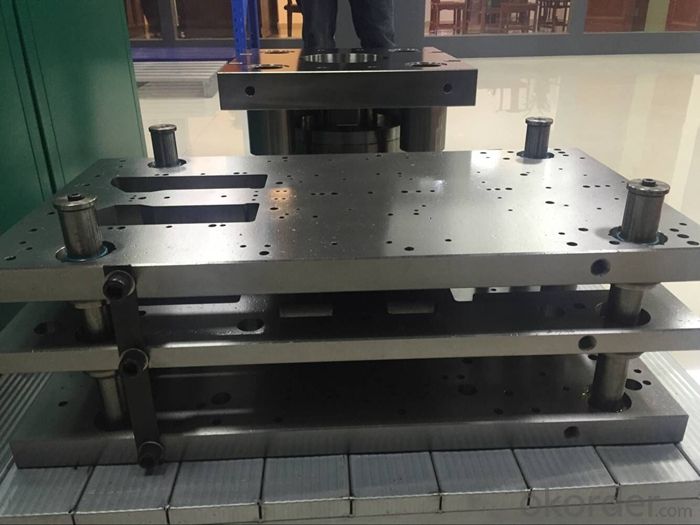

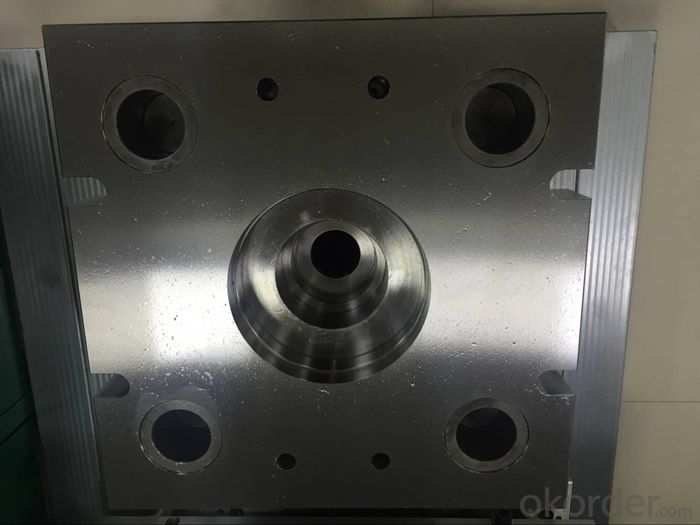

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:The application of hydraulic cylinder in mould

- Slide block, core. Some places are for the convenience of the model, some places are for release.

- Q:The function of die water board?

- Plastic mould is divided into two plate mold, three board mould, three board mould is two open mold, mold has a nozzle plate, nozzle plate is used to open mold for the first time the shuikou material pull out from water mouth, and then move back as the mould, due to the limit lever pull nozzle plate, injection molded parts and runner plate on the dynamic model of shuikou disconnect, complete the whole process of open mould.

- Q:What is the cooling system of the mold

- The simple thing is that the temperature of the mold is high enough to keep the cooling system constant

- Q:What are the types of molds?

- Sheet metal discharging, hot-rolled, cold-rolled, hot coil, cold rolled sheet metal processing, deep drawing, integer, bending, punching, blanking, non-ferrous metal casting, powder metallurgy, plastic parts, injection molding, blow molding (plastic bottles), extruded (pipe) mold other categories: alloy mold, metal mold, plastic mold, stamping mold, casting die, forging die, injection mould, die-casting mould, auto mould, thread rolling die

- Q:What is the design philosophy of the mould?

- In the early failure mode of the die, the fracture of the die, the collapse of the molds, the crack in the bottom of the cavity and the cracks in the bottom of the die. The factors affecting die life are more, and the design of die is the foundation of die life. The design of die design is the structure design of the die, the design of forming mould cavity and the determination of mould steel, mould hardness and so on. Mould manufacturing process refers to molding process, heat treatment specification and surface treatment technology. This paper discusses the measures to improve die life from two aspects: mould design and mould manufacturing.

- Q:How to choose the injection molding machine when the mould design

- 1, according to the weight of the product, the thickness of the die and the thickness of the die, the width and height of the die.

- Q:There are several types of mould

- Rubber mold: it is divided into pressing mould, injection molding and extrusion molding. The processing of rubber. Glass: it is divided into press and die. Processing glass. Casting mould: it is divided into sand mold, shell mold, lost wax mould, pressure casting mould and metal mold. Process melt alloy.

- Q:What is the pull mold

- The drawing die is also called drawing die, which is used to pull metal plates deep into cups or curved parts. For example, small metal cups or large car body shapes.

- Q:Mold design and manufacturing to learn which courses

- This major is mainly aimed at machinery manufacturing, and develops the design and manufacture of cold stamping die, type cavity mold and its design and manufacturing. Main courses: mechanical drawing, mechanical design basis, electrician and electronic technology, engineering materials and heat treatment, mould manufacturing technology, mould CAD/CAM. Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel. Tuition is too expensive This is a professional professional, and it's easy to find a job. The school that runs this major is very few in the vocational technical college Jobs: workers, molds manufacturing personnel, mechanical maintenance personnel, production management personnel.

- Q:The difference between wire cutting and mold making

- (4) test and test. Because of the characteristics of the mould and the experience of mould design, the mould must pass the test or the test pressure after assembly, and finally determine whether it is qualified. At the same time, there are some parts that need to be tested to be finalised. Therefore, there must be a certain testing period for the production schedule. (5) the machining of molds to mechanization, elaboration and automation. At present, the demand of product parts for mould accuracy is higher and higher, high accuracy, high life, high efficiency and more and more. The machining accuracy depends mainly on the precision of machine tool, the processing technology condition, the measuring method and the method. At present, precision molding grinding machine, CNC precision surface grinding machine, precision CNC wire-cut edm machine, precision continuous trajectory coordinates grinder and the use of three coordinates measuring machine is becoming more common, mould processing to the intensive development of high and new technology.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Die-casting Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords