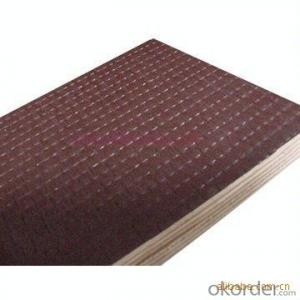

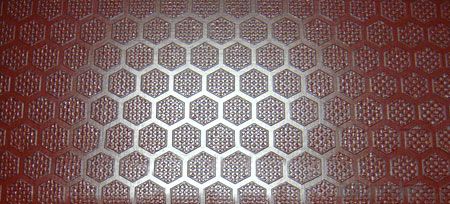

Diamond Design Anti-slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification

Anti-slippery film faced plywood

Size:1220X2440mm ,1250X2500mm

Glue:MR,WBP

Core:poplar,hardwood,combi

F/B:balck,brown,red

Description

Size: | 1220*2440cm or as request |

core | poplar,pine,birch,hardwood,etc |

Film | black film |

Face | film faces one sides or two |

Feature | strong nailing strength and easy to be coated |

Processing of pressing | Third or second |

Determination of gule strength | 2.96Mpa |

Moisture content | 7-15% |

Elastic modulus | 5000-6000mPA |

Features:

1. No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2. Good performance and more turnover use time.

3. It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4. Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5. This can moderate and contact 30% time for a project.

6. Corrosion resistant and ir will nor pollute the surface of concrete.

7. It is good to keep performance warm,ia favorable to make constrution in winter.8. Products can be made into warping plywood

9. It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different types.

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q:Multilayer board and plywood difference

- multi-layer board is one of the commonly used materials processing enterprises, is a wood-based panel

- Q:Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q:What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q:Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Thickness from 4mm below the thin plywood. 3mm, 3.5mm, 4mm thick plywood for common specifications

- Q:One of the commonly used materials for furniture is a wood-based panel

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each othe

- Q:What harm does the plywood factory work?

- occupational chronic benzene poisoning refers to the workers in the professional activities Long-term exposure to benzene vapor caused by hematopoietic system damage as the main manifestation of systemic disease.

- Q:What is the use of plywood for construction?

- and triclines (commonly known as the three-plate, five per cent, nine per cent, thirteen board)

- Q:What are the advantages and disadvantages of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q:Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

- Q:Classification of plywood for construction

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Diamond Design Anti-slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords