Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.convenient scaffolding system

2.industrial buildings and civil buildings

Convenient Ring - Lock Scaffold Formwork For Industrial, Civil Buildings

Description:

Brief introduction

A convenient scaffolding system, especially for load-bearing support, its structure is simple and reasonable, its operation is easy and flexible, and the system is widely used in industrial buildings and civil buildings.

Competitive advantage

①. Product standardization, produce cost is lowered.

As the picture left shown, the standard is auto-welded; all the distance between cross plates of standards with different length is 500mm, which makes the auto-welded working method be easily achieved.

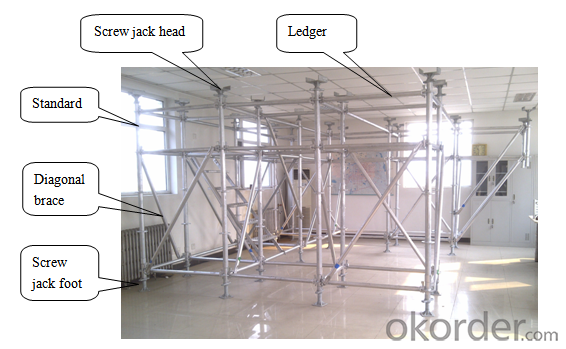

②. Spatial tower assembly guarantees high load-bearing capacity.

The main body of RL-scaffolding system is consisted of standard, ledger, diagonal ledger, and diagonal brace. The system forms a whole spatial frame structure that guarantees its high load-bearing capacity.

③.Smart joint design guarantees safe application and easy operation.

As the picture below shown, the “connect head” stuck in the position of cross plate with correct hole, then fix the pins tightly with a hammer, after that, you finish the whole connection work. The joint is safe and firmly.

Applications

- Q:Can steel tube couplers be used for both single and multi-level scaffolding structures?

- Yes, steel tube couplers can be used for both single and multi-level scaffolding structures. Steel tube couplers are versatile and can be easily attached to various types of scaffolding tubes, enabling them to be used in different configurations and adapt to the needs of single or multi-level scaffolding structures.

- Q:How do steel tube couplers prevent tubes from bending under load?

- Steel tube couplers prevent tubes from bending under load by providing a secure connection between two tubes. These couplers are designed to fit tightly around the ends of the tubes and are typically fastened using bolts or other mechanical means. The couplers distribute the load evenly across the connected tubes, ensuring that the weight or force applied to one tube is transferred to the other without causing bending or deformation. By creating a strong and rigid connection, the couplers effectively prevent the individual tubes from bending under load. Furthermore, the design and material of steel tube couplers contribute to their ability to prevent bending. They are typically made of durable and rigid steel that can withstand high loads and resist deformation. This strength and rigidity help to maintain the structural integrity of the tubes and prevent them from bending or buckling. Overall, steel tube couplers play a crucial role in ensuring the stability and strength of connected tubes by preventing them from bending under load. Their secure connection and sturdy construction distribute the load evenly, maintaining the integrity of the tubes and preventing any potential bending or deformation.

- Q:I got my scaffold piercing about 2 weeks ago now. It hurt of course for the first few days, and then the pain went away. Over the past few days the piercing at the front has become very swollen and red, and is throbbing, as though i have a heart beat in that section of my ear. It is also producing crusty stuff inside my ear and outside. What does this mean? Or is this 'normal' Have i just irritated it from catching it etc?Thanks for your help

- Crusting is totally normal. I got my industrial pierced almost a year ago and it got crusty pretty regularly for the first six or seven months, so don't worry about that. Swelling and throbbing are signs or irritation or possible infection. Your ear might just be angry if you've hit it or got it caught on things a few too many times, but it could be infected. Keep washing it with warm salty water and consider having a reputable piercer take a look at it.

- Q:How do steel tube couplers ensure the stability and rigidity of scaffolding structures during use?

- Steel tube couplers ensure the stability and rigidity of scaffolding structures during use by providing a secure connection between the steel tubes. These couplers are designed to grip the tubes tightly, preventing any movement or slippage. This ensures that the scaffolding remains stable and rigid, even when subjected to various loads and forces. The strong and reliable connection created by the couplers enhances the overall structural integrity of the scaffolding, ensuring the safety of workers and the stability of the platform.

- Q:Can steel tube couplers be used for scaffolding structures that need to support cantilevered platforms?

- Steel tube couplers are suitable for scaffolding structures requiring support for cantilevered platforms. These couplers are frequently employed in scaffolding systems to establish a secure and robust framework by connecting and fastening the tubes together. By extending the scaffold tubes beyond the primary structure, cantilevered platforms can be upheld, and steel tube couplers can be utilized to securely link these extended tubes. Nevertheless, it is vital to engage professionals who adhere to safety guidelines and regulations during the design and assembly of the scaffolding to ensure the stability and safety of the structure.

- Q:How do you inspect steel tube couplers for any signs of damage or wear?

- Inspecting steel tube couplers for signs of damage or wear is essential to ensure their structural integrity and prevent potential accidents or failures. Here are some steps to follow in order to effectively inspect steel tube couplers: 1. Visual Inspection: Begin by visually examining the coupler for any obvious signs of damage or wear. Look for cracks, dents, corrosion, or any other visible abnormalities. Pay attention to the surface condition, edges, and welds. 2. Cleanliness: Before proceeding with a more detailed inspection, ensure that the coupler is thoroughly cleaned. Remove any dirt, debris, or coatings that may obstruct your view of potential damage. 3. Magnifying Tools: Utilize magnifying tools such as a magnifying glass or microscope to closely examine the coupler's surface. This will help identify small cracks, pitting, or other signs of wear that may be difficult to see with the naked eye. 4. Non-Destructive Testing: Consider employing non-destructive testing techniques such as ultrasonic or magnetic particle testing. These methods can detect hidden defects and cracks that may not be visible from the surface. 5. Dimensional Inspection: Verify that the coupler's dimensions conform to the required specifications. Measure the inner and outer diameters, thickness, and length to ensure they align with the manufacturer's guidelines. 6. Load Testing: If necessary, subject the coupler to load testing to assess its strength and structural integrity. This can be done by applying a predetermined load and monitoring for any signs of deformation or failure. 7. Documentation: Document all findings and observations during the inspection process. This will help track any changes or trends over time and aid in making informed decisions regarding maintenance or replacement. 8. Regular Inspections: It is recommended to conduct periodic inspections of steel tube couplers, especially in high-stress applications or environments. Regularly check for signs of wear, corrosion, or any other potential issues to ensure the couplers remain in optimal condition. By following these steps, you can effectively inspect steel tube couplers and identify any signs of damage or wear. Regular inspections and maintenance will help ensure the safety and longevity of the couplers, minimizing the risk of failures or accidents.

- Q:Can steel tube couplers be used for scaffolding on uneven surfaces?

- Yes, steel tube couplers can be used for scaffolding on uneven surfaces. The couplers are designed to connect steel tubes securely, allowing for flexibility and adjustment to accommodate uneven ground. This ensures stability and safety while erecting scaffolding on varying terrains.

- Q:What are the common sizes of steel tube couplers used in scaffolding?

- The sizes of steel tube couplers used in scaffolding can vary depending on the specific requirements and standards of the project or region. Some commonly used sizes include 48.3mm, 60.3mm, and 76.1mm. These sizes are typically utilized to connect steel tubes of corresponding dimensions, ensuring the stability and security of the scaffolding structure. It should be noted that the actual sizes may differ based on factors like load capacity, design standards, and regulations of the project or country. Therefore, it is essential to refer to the relevant scaffolding guidelines and standards prior to selecting the appropriate size of steel tube couplers for scaffolding purposes.

- Q:What are the recommended torque specifications for tightening steel tube couplers?

- The recommended torque specifications for tightening steel tube couplers can vary depending on the specific coupler and manufacturer. It is advisable to consult the manufacturer's guidelines or specifications provided with the couplers to ensure the proper torque is applied during tightening.

- Q:How do steel tube couplers affect the overall flexibility of a scaffolding system?

- Steel tube couplers play a crucial role in determining the overall flexibility of a scaffolding system. These couplers are used to connect steel tubes together, allowing for the construction of various configurations and designs. The type and arrangement of couplers used in a scaffolding system can significantly impact its flexibility. For instance, swivel couplers allow for a 360-degree rotation, enabling the scaffolding to be adjusted to different angles and positions. This flexibility is essential when constructing scaffolding around obstacles or irregular structures. Moreover, steel tube couplers provide a strong and secure connection between tubes, ensuring stability and safety in the scaffolding system. By effectively distributing the load between different components, the couplers enhance the overall strength and rigidity of the scaffolding structure. However, it is important to note that excessive use of couplers can limit the flexibility of the scaffolding system. The more couplers used, the more rigid and less adaptable the structure becomes. Therefore, it is vital to strike a balance between the number of couplers and the desired flexibility of the scaffolding system. In conclusion, steel tube couplers impact the overall flexibility of a scaffolding system by providing the necessary connections between tubes. The type and arrangement of couplers determine the range of angles and positions that can be achieved, while ensuring stability and load distribution. However, it is crucial to find the right balance between coupler usage and flexibility to create a safe and adaptable scaffolding structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Detailed Product Description/

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords