Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

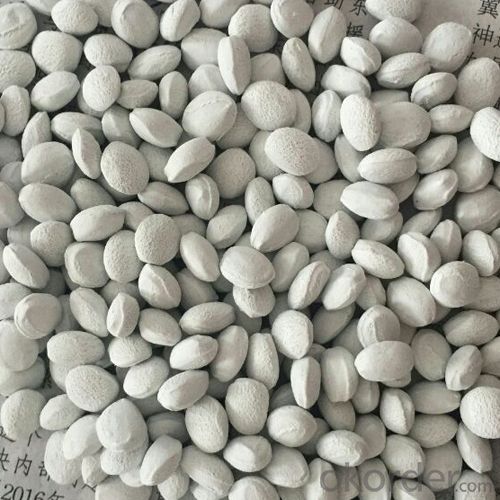

Desiccant masterbatch (also called defoaming agent, anti foam agent ).

It is suitable for all kinds of enterprises which make product with PP/PE recycled plastic material.

The bubble ,moire fringe, crack ,stain problems will be solved by adding efficient anti-foam masterbatch .

Application Method:

Production process can be achieved by mixing this masterbatch with damp plastic materials symmetrical. 1%--2% amount is recommended in blow molding,2%-5% is recommended in sheet and injection molding.

Customers decide the amount according to the condition of plastic dampness.

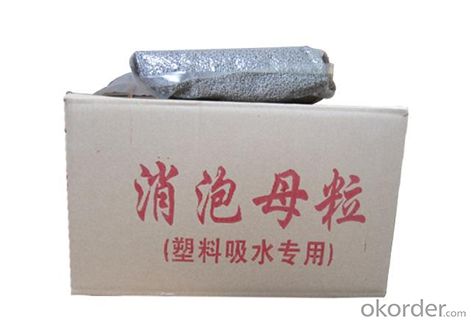

Packaging:Vacuum package, 2.5kg or 5 kg of each, it can not be store open,keep out of sunny peacan.

Advantage of Desiccant Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Desiccant Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of Desiccant Masterbatch:

- Q:What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- Water absorbency. Nylon has high water absorption, and saturated water can reach more than 3%. To a certain extent, the dimensional stability of the parts is affected

- Q:What plastic material is used for plastic hose?

- PP: good corrosion resistance, high strength, high surface hardness, good surface finish, have certain resistance to high temperature hot melt welding, flange connecting thread, sea water, oil and chemical sewage irrigation pipe, concrete floor for indoor heating system for heating pipe

- Q:Does plastic raw material ENBA have toughening effect?

- EMA can be used as toughening agent for alloy such as PBT/PC and PC/ABS.

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- There are PC lensesThe PC material is more impact resistant than polymer resin, often used in aviation equipment transparent windows, police on the mask, and the astronaut's helmet mask, it is only about 1/10 the weight of glass, resin lenses compared with traditional is only half of the weight.

- Q:Characteristics of rigid polyurethane foam made of polyurethane raw material

- Rigid polyurethane foam in the developed countries, building hard polyurethane hard foam accounted for the total consumption of about 70%, is a refrigerator, freezers and other hard foam dosage more than doubled; in China, application of rigid foam in construction industry is still not as common in western developed countries, so the development potential is very big.

- Q:What is the plastic bag made of?

- The main raw material of plastics is oil and natural gas, that is, carbon hydrogen compounds. First, the appropriate macromolecular components in petroleum and natural gas are extracted, first split into monomers, and then polymerized into polymers to become plastic

- Q:What are the materials for making plastic basins? Are they raw materials?

- PP material ah! Usually with raw materials, slightly more mouth material!

- Q:ABS plastic storage conditions

- If it is ABS raw materials, storage: rainproof, moisture-proof, anti lightPacking is best provided with a PE inner bag for moisture proofThere is no place to pay more attention.

- Q:What raw material (HDPE) made of plastic bags, high transparency, good sense of light master?

- Plasticizers can increase plasticity and softness of plastics, reduce brittleness, and make plastics easy to process and shape. Plasticizers are generally miscible with resins, nontoxic, odorless, and highly volatile organic compounds that are stable in light and heat. The most commonly used are phthalate two formic acid esters. For example, the production of PVC plastic, if you add more plasticizers, you can get soft PVC plastic, if not added or less plasticizer (dosage <10%), then hard PVC plastic.

- Q:What are the raw materials for vest plastic bags?

- Polyvinyl chloride, referred to as PVC, and the formula is (CH2 - CH2) n, is the most important kind of vinyl polymer, is the world's second largest plastic varieties after polyethylene. In China, the yield is the first in plastics. In the printing industry, packaging production of books, folders, tickets and other frequently used PVC calendered film cover color and transparent glazing film.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords