Demolished Vertical Pipeline Pump Model ISGB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

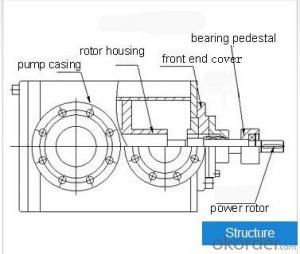

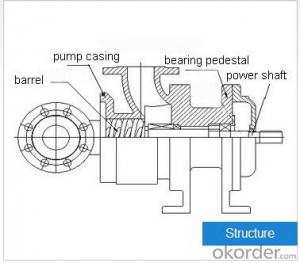

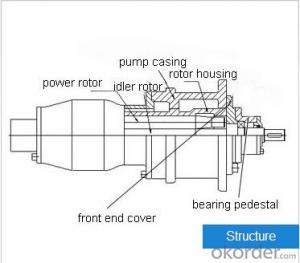

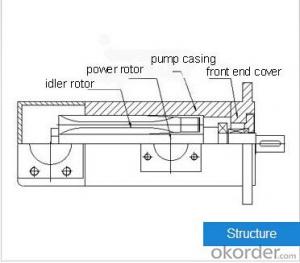

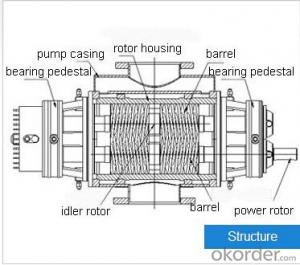

ISGB type demolished vertical pipeline centrifugal pump is a structural basis for the development of the ISG-type pump successful novel, advanced technology products. The vertical pump designed especially for bold breakthrough in the overall structure. Using an independent shaft support bearing body, to solve the original vertical pump at the motor shaft support deficiencies. The hydraulic model pump impeller, eliminating the original vertical shaft to force deficiencies. Y series motor is a standard universal motor, to solve the original vertical axis motor pump plus supporting replace male problems, while 100% of the structure will be demolished, to solve the replacement of high-power pump impeller shaft bearing mechanical seal problems.

The pump compared with similar domestic products, with a long matching easier and more convenient maintenance and other irreplaceable advantages Geng smooth functioning life. In the case of vertical pump products in the domestic front, the technical lead at home is an alternative ISG vertical centrifugal pump IS S-type double-suction centrifugal pumps and other conventional variety of the best products.

Features

1. Vertical structure, easy installation, the unique design of the motor and pump body connector connected, high precision and high concentricity greatly reduced footprint, reduced pumping station construction investment of 30% -60%, the foot stable structure compact appearance of fine casting and vertical centrifugal processing gives new beauty, make the product attractive glow products can be comparable with the famous manufacturers of vertical pumps

2. Equipped with well-known domestic manufacturers of Y series standard universal motor, smooth running, low noise

3. adopt international famous brand bearing precision bearings, high precision, good reliability, long life

4. impeller 90s finest self-balancing axial force hydraulic model, making the pump bearing and mechanical seal life greatly extended.

5. Motor bearing housings are equipped with internal filling hole and drain hole, bearing maintenance and repair is very convenient

6. Removable rigid coupling in the middle of the pump start no vibration noise, rotating parts offers a reliable security guards, security excellent

7. tungsten carbide mechanical seal with stainless steel and other materials, high temperature high pressure long operating life, no leakage, no wear on the shaft to ensure that the work environment clean

8. The structure of the unique design of the pump cover, just remove the rigid intermediate pump coupling nut, then remove the bearing very lightweight pump cover impeller shaft assembly, replace the mechanical seal box impeller, to say nothing of the body without having to disassemble the motor and pipelines, convenient maintenance

Working conditions

1. The maximum working pressure pump system for 1.6MPA, ie pump suction pressure + pump head ≤1.6MPA

2. other liquid transport medium is water or physical and chemical properties similar to water

3. Environmental temperature T≤40 ℃, altitude ≤1000M, relative humidity ≤95%

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Demolished Vertical Pipeline Pump Model ISGB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products