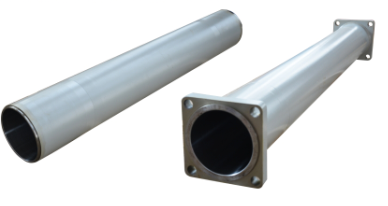

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN205 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

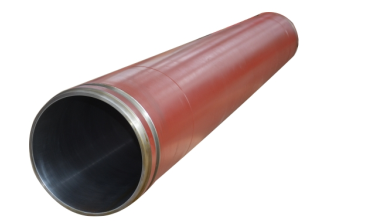

Concrete Pump Delivery Cylinder DN205*2284

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN205*2284

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:How often should concrete pump water pumps be inspected and replaced?

- The frequency of inspection and replacement for concrete pump water pumps depends on several factors including the workload, operating conditions, and maintenance practices. Generally, it is recommended to inspect the water pump at least once a month to ensure its proper functioning. During the inspection, it is important to check for any leaks, unusual noises, or signs of wear and tear. If any issues are identified, immediate action should be taken to resolve them, such as repairing or replacing damaged parts. As for replacement, it is difficult to provide an exact timeframe as it varies depending on the quality of the pump, the intensity of use, and the level of maintenance. However, a general guideline is to consider replacing the water pump every 1-2 years for heavy usage or every 3-5 years for moderate usage. Regular maintenance, such as cleaning and lubricating the pump, can extend its lifespan and minimize the need for frequent replacements. It is important to note that these recommendations are general guidelines and may vary depending on the specific manufacturer's instructions, industry standards, and local regulations. It is advisable to consult the manufacturer's guidelines and seek professional advice from experts in the field to determine the appropriate inspection and replacement schedule for concrete pump water pumps in your specific circumstances.

- Q:How often should hopper pins be inspected or replaced in a concrete pump?

- To guarantee the safe and efficient operation of concrete pump equipment, it is imperative to regularly inspect and replace hopper pins. The frequency of these inspections and replacements depends on various factors, including the concrete pump's usage and the condition of the hopper pins. As a general rule, it is advised to inspect hopper pins every three to six months or after every 400 to 600 hours of operation. However, it is crucial to note that this timeframe can differ depending on the intensity and volume of concrete pumping activities. During the inspection, it is necessary to carefully examine the hopper pins for any indications of wear, damage, or deformation. If any pins display significant signs of wear, such as cracks, elongation, or excessive corrosion, they should be promptly replaced to prevent potential accidents or equipment failure. Maintaining the structural integrity of the concrete pump and ensuring the safety of operators and the surrounding environment rely heavily on regular inspection and replacement of hopper pins. It is advisable to consult the manufacturer's guidelines or seek professional advice to determine the specific schedule for inspection and replacement, considering the make and model of the concrete pump.

- Q:What are the advantages of using stainless steel components in concrete pump spare parts?

- There are several advantages of using stainless steel components in concrete pump spare parts. Firstly, stainless steel has excellent corrosion resistance, which ensures the longevity and durability of the spare parts even in harsh environments. Secondly, stainless steel is known for its high strength-to-weight ratio, providing increased strength and reliability without adding excessive weight to the concrete pump. Additionally, stainless steel is highly resistant to wear and tear, which reduces the need for frequent replacements and maintenance. Lastly, stainless steel components offer a hygienic and clean surface, making them suitable for applications in the construction industry where cleanliness is crucial.

- Q:Are there any specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pipe or hose assemblies in concrete pump spare parts. These guidelines ensure the proper and safe functioning of the pump system. Here are some key guidelines to follow: 1. Size and Compatibility: The pipe or hose assemblies should be of the appropriate size and compatible with the concrete pump system. They should match the pump's specifications and be designed for the intended application. 2. Correct Alignment: Proper alignment of the pipe or hose assemblies is crucial for efficient operation. They should be installed straight without any kinks or bends that could restrict the flow of concrete or cause blockages. 3. Secure Connections: All connections, including fittings and couplings, should be securely tightened to prevent leaks or disconnections during operation. It is recommended to use proper tools and techniques to ensure tight and reliable connections. 4. Support and Protection: Pipe or hose assemblies should be adequately supported and protected to prevent damage or wear. They should be securely fastened to prevent excessive movement or vibration during pumping operations. 5. Clearances and Accessibility: Sufficient clearances should be maintained between the pipe or hose assemblies and any surrounding structures or equipment to allow for easy inspection, maintenance, and replacement if needed. 6. Proper Sealing: All joints and connections should be properly sealed using suitable sealing materials to prevent leakage. This is essential for maintaining the integrity of the pumping system and preventing any environmental or safety hazards. 7. Regular Inspection and Maintenance: It is important to regularly inspect the pipe or hose assemblies for any signs of wear, damage, or degradation. Any issues should be addressed promptly to ensure the continued safe operation of the concrete pump system. Following these guidelines will help ensure the proper installation of pipe or hose assemblies in concrete pump spare parts, promoting safe and efficient concrete pumping operations. It is also advisable to consult the manufacturer's recommendations and refer to any specific guidelines provided with the spare parts.

- Q:Are there any specific maintenance practices for concrete pump spare parts?

- Yes, there are specific maintenance practices for concrete pump spare parts. Regular inspections, cleaning, and lubrication of the parts are essential to ensure their proper functioning and longevity. It is also important to follow manufacturer's guidelines and recommendations for maintenance and replacement of worn-out parts. Proper storage and handling of spare parts can also contribute to their durability and effectiveness.

- Q:How can one identify the need for replacement of concrete pump spare parts?

- One can identify the need for replacement of concrete pump spare parts by observing any signs of wear and tear, such as cracks, leaks, or damage to the components. Additionally, a decrease in pump performance, unusual noises, or difficulty in operation can indicate the need for replacement. Regular maintenance and inspection can also help in identifying any potential issues with the spare parts that may require replacement.

- Q:What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The potential risks associated with the installation and replacement of concrete pump spare parts include: 1. Safety hazards: Improper installation or replacement of spare parts can lead to accidents and injuries, as concrete pumps involve heavy machinery and high-pressure systems. Inadequate training or lack of knowledge can result in mishandling of equipment, leading to accidents for both the operators and nearby personnel. 2. Equipment damage: If the spare parts are not installed correctly, it can cause damage to the concrete pump or other components. This may result in costly repairs and downtime for the equipment, impacting productivity and project timelines. 3. Performance issues: Using incorrect or low-quality spare parts can affect the overall performance and efficiency of the concrete pump. It may result in reduced pumping capacity, increased wear and tear, and decreased reliability, compromising the quality of the concrete being pumped. 4. Warranty and liability concerns: Installing unauthorized or incompatible spare parts can void the manufacturer's warranty, leaving the responsibility for repairs and maintenance solely on the user. In case of any accidents or damages caused by faulty installation, the liability may fall on the individuals or companies responsible for the installation or replacement. To mitigate these risks, it is crucial to ensure proper training and certification for the personnel involved in the installation and replacement of concrete pump spare parts. Adhering to manufacturer guidelines, using genuine spare parts, and regularly inspecting and maintaining the equipment can also minimize potential risks and ensure safe and efficient operations.

- Q:How often should concrete pump lubrication systems be inspected and maintained?

- To ensure proper functioning and longevity, it is essential to regularly inspect and maintain concrete pump lubrication systems. The frequency of inspections and maintenance will vary depending on factors such as the pump type, usage, and manufacturer's recommendations. Typically, it is advised to conduct monthly inspections and maintenance of concrete pump lubrication systems. This regularity allows for early detection of potential issues or wear and tear that may require attention. Furthermore, routine inspections help identify signs of lubricant degradation or contamination, which can affect the system's efficiency and performance. During the inspection, it is crucial to check for leaks, damaged or worn-out components, and ensure adequate greasing of all lubrication points. Additionally, the lubrication system should be cleaned to eliminate any accumulated debris or contaminants. Apart from monthly inspections, certain maintenance tasks should be carried out at regular intervals. These tasks may include lubricant and filter changes, belt and hose adjustments or replacements, and checking the system's pressure and flow to ensure proper operation. It is important to emphasize that the manufacturer's guidelines and recommendations must always be followed for inspecting and maintaining concrete pump lubrication systems. These guidelines may provide specific instructions based on the pump type and model, as well as any unique requirements. By regularly inspecting and maintaining concrete pump lubrication systems, optimal performance can be ensured, downtime can be minimized, and the lifespan of the systems can be extended.

- Q:Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. Here are some general guidelines to follow: 1. Safety precautions: Always ensure that the concrete pump is turned off and depressurized before attempting to install any seal kits or O-rings. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the installation process. 2. Preparation: Thoroughly clean the area where the seal kits or O-rings will be installed. Remove any debris or old seal remnants to ensure a clean and smooth surface for installation. 3. Inspection: Before installing new seal kits or O-rings, inspect them for any defects or damage. If any issues are found, replace the faulty parts with new ones. 4. Lubrication: Apply a small amount of compatible lubricant or hydraulic oil to the seal kits or O-rings to aid in their installation and prevent damage during the process. Be sure to use a lubricant that is compatible with the materials used in the seal kits or O-rings. 5. Proper alignment: Carefully align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Ensure that they are properly seated and positioned before proceeding. 6. Correct installation technique: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid excessive force or bending, as this can lead to damage or improper sealing. 7. Testing: After the installation is complete, test the concrete pump to ensure that the seal kits or O-rings are functioning properly. Check for any leaks or abnormal behavior during operation. 8. Regular maintenance: Once the seal kits or O-rings are installed, it is important to regularly inspect and maintain them to ensure their longevity and optimal performance. Follow the manufacturer's recommended maintenance schedule and guidelines for best results. It is important to note that these guidelines are general in nature and may vary depending on the specific make and model of the concrete pump. Therefore, it is always recommended to consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q:Is the main pump of the concrete pump electric control or hydraulic control?

- Closed main oil pump behind the charge pump to provide a constant pressure to the displacement of the electromagnet by the current control output pressure to achieve the main pump pressure and pumping the commutation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN205 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords