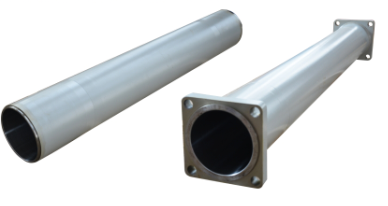

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1587MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*1587

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN200*1587

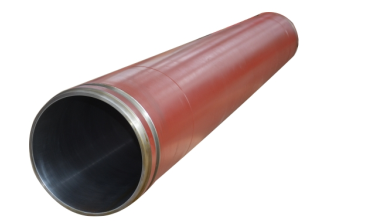

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:What are the types of concrete pumps?

- According to the structure and use of divided into drag type concrete pump, car pump and pump car

- Q:Can I repair concrete pump spare parts instead of replacing them?

- In certain instances, it is indeed possible to repair concrete pump spare parts instead of opting for replacement. There are various components of concrete pump spare parts, including seals, gaskets, valves, and hydraulic elements, that can be effectively repaired. However, the feasibility of repair is contingent upon the severity of the damage and the particular part in need of attention. In situations where the damaged parts are excessively worn or damaged, an effective repair may not be feasible, thus necessitating replacement. To ascertain whether repair is a practical option for your specific concrete pump spare parts, it is imperative to seek advice from a professional or reach out to the manufacturer.

- Q:Can concrete pump spare parts be tested for performance and quality before installation?

- Yes, concrete pump spare parts can and should be tested for performance and quality before installation. Testing these parts prior to installation ensures that they meet the required standards and specifications, and it helps to identify any defects or issues that may affect their performance or lifespan. Testing can be done in various ways, such as conducting physical inspections, performing functional tests, or using specialized equipment to measure specific parameters. By testing these spare parts before installation, any potential problems can be identified and resolved early on, ensuring optimal performance and quality.

- Q:How can one identify the correct part number for a specific concrete pump spare part?

- To identify the correct part number for a specific concrete pump spare part, there are a few steps you can follow: 1. Check the equipment manual: The first place to look is the manual that came with the concrete pump. It should provide a detailed parts list along with their corresponding part numbers. This is the most reliable and accurate source of information. 2. Contact the manufacturer: If you don't have access to the equipment manual or if it doesn't provide the necessary information, reach out to the manufacturer directly. They should be able to assist you in identifying the correct part number for the specific concrete pump spare part you need. Provide them with as much information as possible, such as the make, model, and serial number of the concrete pump. 3. Use online resources: There are various online platforms and parts catalogs available that provide detailed information about spare parts for different concrete pump brands and models. These resources often allow you to search for the part based on the make and model of your concrete pump. Make sure to cross-reference the information you find with the manufacturer's specifications to ensure accuracy. 4. Consult with a local dealer or distributor: If you are unable to find the correct part number through the above methods, consider reaching out to a local dealer or distributor of concrete pump spare parts. They often have extensive knowledge and experience in identifying and sourcing the right parts for different equipment. Provide them with all the necessary details about your concrete pump, and they should be able to assist you in finding the correct part number. Remember, accuracy is crucial when identifying the correct part number for a specific concrete pump spare part. Using reliable sources and consulting with professionals will help ensure that you obtain the right part for your equipment's needs.

- Q:What is the difference between concrete pump and ground pump?

- The pump is easy to move and flexible, but generally limited to the length of the boom by 60-70m. The ground pump is not limited by height, but it needs to be connected with the conveying pipe, which is of poor flexibility

- Q:Can I get spare parts for both concrete pumps with and without agitators?

- Yes, you can get spare parts for both types of concrete pumps - those with agitators and those without. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to ensure the smooth operation and maintenance of these machines. These spare parts include but are not limited to wear plates, cutting rings, delivery cylinders, pistons, seals, hoses, valves, and filters. It is recommended to contact the manufacturer or authorized dealers of the specific concrete pump brand you are using to inquire about the availability and pricing of spare parts for both types of pumps.

- Q:How can a faulty pressure gauge affect the concrete pumping process?

- A faulty pressure gauge can significantly impact the concrete pumping process in several ways. Firstly, it may provide inaccurate readings, leading to an incorrect assessment of the pressure within the system. This can result in either excessively high or low pressure being applied during the pumping process, which can lead to various issues. If the faulty pressure gauge displays a higher pressure than the actual value, it may cause over-pressurization of the concrete pump. This can lead to potential damage to the equipment, such as burst hoses or pipes, which can be dangerous for workers nearby. Additionally, excessive pressure can cause the concrete to be pumped too forcefully, potentially leading to the material splattering or leaking from the delivery system, resulting in wastage and an uneven distribution of the concrete. On the other hand, an incorrectly low pressure reading from the faulty gauge can have its own set of problems. Insufficient pressure within the pumping system can result in the concrete not being adequately delivered to the desired location. This can cause delays in the construction process and result in uneven or incomplete concrete placement, affecting the integrity and strength of the structure being built. Moreover, a faulty pressure gauge may also contribute to inaccurate monitoring of the concrete's slump or consistency. The pressure gauge is often used as an indicator of the concrete's flowability, and if the gauge is faulty, it may provide misleading information about the material's workability. This can result in the concrete mix being either too fluid or too stiff, leading to difficulties in pumping and potentially compromising the quality of the finished concrete structure. In conclusion, a faulty pressure gauge can have severe consequences on the concrete pumping process. It can lead to over-pressurization, material wastage, uneven distribution, delays in construction, and compromised concrete quality. Therefore, it is crucial to regularly inspect and maintain pressure gauges to ensure their accuracy and reliability, promoting safe and efficient concrete pumping operations.

- Q:How long does it take to receive concrete pump spare parts after placing an order?

- The time it takes to receive concrete pump spare parts after placing an order can vary depending on several factors. Firstly, it depends on the availability of the specific spare parts you have ordered. If the parts are readily available in stock, the delivery time can be relatively quick. However, if the parts are not in stock and need to be manufactured or sourced, it may take longer to receive them. Secondly, the location and distance between the supplier and your location also play a role in the delivery time. If the supplier is in close proximity, the parts can be delivered within a few days. However, if the supplier is located far away or in a different country, it may take longer due to shipping and customs processes. Furthermore, the shipping method you choose can also impact the delivery time. Expedited shipping options can ensure quicker delivery, but at an additional cost. Standard shipping methods may take longer but are usually more cost-effective. Lastly, the efficiency and responsiveness of the supplier also come into play. A reliable supplier with a streamlined ordering and shipping process will likely be able to deliver the spare parts in a shorter time frame. In conclusion, the time it takes to receive concrete pump spare parts after placing an order can vary based on factors such as availability, location, shipping method, and supplier efficiency. It is advisable to inquire about estimated delivery times when placing the order to have a better understanding of when the parts will be delivered.

- Q:How can you determine when a concrete pump pipe needs to be replaced?

- Determining whether a concrete pump pipe requires replacement involves several factors to consider. 1. Visual Examination: Thoroughly inspect the pipe visually, searching for cracks, damages, or indications of wear and tear. Pay close attention to the pipe's ends where it connects to the pump and nozzle, as these regions are more susceptible to damage. 2. Performance Assessment: Observe the concrete pump's performance. If there is a decline in pumping efficiency, such as reduced output or difficulties in maintaining pressure, it may indicate a pipe problem. Furthermore, excessive leakage or blockages in the pipe could signify the need for replacement. 3. Age and Usage: Take into account the pipe's age and the extent of its usage. Concrete pump pipes have a limited lifespan, and over time and extensive use, they can deteriorate and lose their structural integrity. If the pipe is old and has undergone substantial use, it might be time for a replacement. 4. Regular Maintenance and Repairs: Frequent repairs or maintenance on the pipe could suggest that it is approaching the end of its lifespan. While regular maintenance can extend the pipe's life, if repairs are becoming more frequent and costly, it may be more cost-effective to replace it. 5. Safety Considerations: Prioritize safety when deciding on pipe replacement. If there are significant structural issues or concerns about the pipe's ability to handle pressure, it is crucial to replace it to prevent potential accidents or hazardous situations. Ultimately, the decision to replace a concrete pump pipe should be based on a combination of visual inspection, performance evaluation, age, usage, regular maintenance, and safety considerations. It is advisable to seek guidance from a professional or experienced technician who can assess the pipe's condition and offer expert advice on whether replacement is necessary.

- Q:How often should hopper cylinders be inspected or replaced in a concrete pump?

- Hopper cylinders in a concrete pump should be inspected regularly to ensure optimal performance and prevent potential malfunctions. The frequency of inspections and replacements depends on several factors, including the intensity of usage, the type of concrete being pumped, and the overall condition of the equipment. As a general guideline, it is recommended to inspect hopper cylinders at least on a monthly basis or after every 100 hours of operation, whichever comes first. During these inspections, the cylinders should be thoroughly examined for any signs of wear, corrosion, or damage. Additionally, the seals, gaskets, and other components connected to the cylinders should be checked for proper functioning. However, it is important to note that the inspection frequency may need to be increased if the concrete being pumped contains abrasive materials or if the pump is being used in harsh environmental conditions. In such cases, more frequent inspections and replacements may be necessary to avoid unexpected breakdowns and costly repairs. Ultimately, the goal is to maintain the hopper cylinders in good condition and address any issues promptly. Regular inspections, along with routine maintenance and proper cleaning, can significantly prolong the lifespan of the cylinders and ensure the concrete pump operates efficiently and safely.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1587MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords