Deformed Bars Grade JIS G3112-2004 SD345

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Deformed Bars Grade JIS G3112-2004 SD345

Details of Deformed Bars Grade JIS G3112-2004 SD345

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Deformed Bars Grade JIS G3112-2004 SD345

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

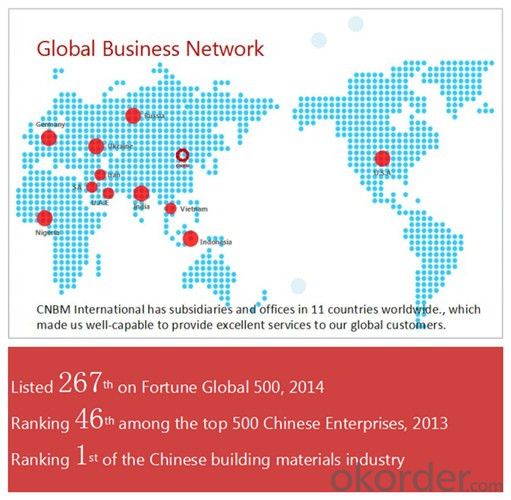

CNBM Introduction of Deformed Bars Grade JIS G3112-2004 SD345 Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Deformed Bars Grade JIS G3112-2004 SD345

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the applications of special steel in the automotive manufacturing process?

- Special steel is widely used in the automotive manufacturing process for various applications. It is commonly used for making engine components like crankshafts, camshafts, and connecting rods due to its high strength and resistance to wear and heat. Special steel is also used for manufacturing suspension systems, steering components, and chassis parts, as it offers excellent mechanical properties and durability. Additionally, special steel is utilized in the production of safety features such as seatbelt components and airbag systems, ensuring the highest level of protection for occupants. Overall, special steel plays a crucial role in enhancing the performance, reliability, and safety of vehicles in the automotive industry.

- Q:What are the main advantages of using special steel in the construction of bridges?

- The main advantages of using special steel in the construction of bridges are its high strength-to-weight ratio, excellent corrosion resistance, and durability. Special steel possesses superior mechanical properties, allowing for the construction of lighter and more efficient bridge structures. It also offers enhanced resistance to environmental factors like moisture, temperature variations, and chemical exposure, leading to longer service life and reduced maintenance costs. Additionally, special steel facilitates the use of innovative and complex bridge designs, enabling architects and engineers to create unique and aesthetically pleasing structures.

- Q:How does special steel contribute to the aerospace turbine industry?

- The aerospace turbine industry greatly relies on special steel due to its unique advantages that cannot be found in other materials. Special steel is renowned for its exceptional strength and durability, making it perfect for enduring the extreme conditions within aerospace turbines. The demanding temperatures, pressures, and rotational speeds experienced by turbine components necessitate a material that can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel demonstrates excellent heat resistance and corrosion resistance properties, which are vital for the longevity of turbine components. Its ability to resist oxidation and corrosion enables special steel to maintain its structural integrity and functionality over extended periods, reducing the need for frequent maintenance or replacement. Moreover, special steel offers outstanding machinability and formability, enabling the production of intricate and complex turbine components. This facilitates the creation of highly efficient and precisely engineered turbine blades, vanes, and other crucial parts necessary for the optimal performance of aerospace turbines. Additionally, special steel provides the necessary characteristics for enhanced fuel efficiency in aerospace turbines. By utilizing high-strength special steel alloys, turbine manufacturers can design lighter and more aerodynamic components, resulting in reduced overall weight and drag. Consequently, this leads to increased fuel efficiency and lower emissions, contributing to a more sustainable and environmentally friendly aviation industry. In conclusion, special steel plays a vital role in the aerospace turbine industry by delivering the required strength, durability, heat resistance, corrosion resistance, and machinability essential for the efficient and dependable operation of turbine components. Its contribution extends to improved fuel efficiency, reduced maintenance needs, and enhanced overall performance, establishing it as an indispensable material for the aerospace turbine industry.

- Q:What are the main characteristics of alloy steel forgings?

- Alloy steel forgings possess several key characteristics that make them highly desirable in various industries. Firstly, alloy steel forgings are known for their exceptional strength and durability. The inclusion of different alloying elements, such as chromium, nickel, molybdenum, and vanadium, enhances the steel's mechanical properties, making it resistant to wear, fatigue, and corrosion. Another important characteristic of alloy steel forgings is their versatility. These forgings can be customized to meet specific requirements, whether it be in terms of shape, size, or performance. This adaptability allows for the production of complex and intricate components that are often used in critical applications, such as aerospace, automotive, and oil and gas industries. Additionally, alloy steel forgings exhibit excellent heat resistance and can withstand extreme temperature fluctuations without losing their structural integrity. This property is particularly beneficial in applications where components are exposed to high temperatures or rapid temperature changes, such as gas turbines, boilers, and heat exchangers. Furthermore, alloy steel forgings offer superior machinability and weldability, making them easier to work with during the manufacturing process. This characteristic allows for precise shaping, forming, and machining of the forgings, enabling manufacturers to achieve intricate designs and tight tolerances. Lastly, alloy steel forgings are known for their cost-effectiveness. Despite their exceptional properties, alloy steel forgings can be produced in large quantities, resulting in economies of scale. This makes them a cost-efficient choice for various industries looking to balance performance, durability, and affordability. In summary, the main characteristics of alloy steel forgings are their exceptional strength, durability, versatility, heat resistance, machinability, weldability, and cost-effectiveness. These qualities make alloy steel forgings a preferred choice for applications requiring high-performance components that can withstand challenging conditions.

- Q:What are the different surface hardening techniques for special steel?

- There are several surface hardening techniques for special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening.

- Q:How does special steel contribute to the overall economy?

- Special steel contributes to the overall economy in various ways. Firstly, special steel is widely used in industries such as automotive, construction, energy, and machinery, among others. Its unique properties and characteristics make it a preferred material for manufacturing high-performance and durable products. This demand for special steel drives economic growth by creating jobs in the steel industry and related sectors. Additionally, the production and export of special steel contribute to a country's export earnings, thus boosting its trade balance and overall economic performance. Many countries with thriving steel industries, such as China, Japan, and Germany, have significantly benefited from the export of special steel products. Moreover, the development and advancement of special steel technologies have a positive impact on innovation and research and development (R&D). Companies in the steel industry invest in R&D to improve the properties and performance of special steel. This not only leads to the creation of new and better steel alloys but also drives innovation in other industries that rely on special steel products. Furthermore, special steel plays a crucial role in infrastructure development. It is used in the construction of bridges, buildings, pipelines, and other critical infrastructure projects. The use of special steel in these projects enhances their durability, safety, and longevity, resulting in cost savings over the long term. This, in turn, contributes to economic development by promoting sustainable and efficient infrastructure. Lastly, special steel also contributes to the overall economy by fostering a competitive manufacturing sector. Countries with a strong special steel industry have a competitive advantage in various industries, as they can produce high-quality products more efficiently. This attracts investment, encourages industrial growth, and boosts overall productivity, leading to economic prosperity on a national scale. In conclusion, special steel contributes to the overall economy through its widespread use in various industries, its role in driving export earnings, its impact on innovation and R&D, its contribution to infrastructure development, and its ability to foster a competitive manufacturing sector.

- Q:What are the applications of special steel in the power generation supply chain?

- Special steels have several applications in the power generation supply chain. They are commonly used in the construction of turbines, boilers, and other critical components of power plants. These steels possess high strength, corrosion resistance, and heat resistance properties, making them suitable for the demanding conditions within power generation facilities. Special steels also play a crucial role in the manufacturing of transmission and distribution equipment, such as transformers and generators, ensuring efficient and reliable power transmission. Overall, the applications of special steel in the power generation supply chain contribute to the development of robust and sustainable energy infrastructure.

- Q:How does special steel perform in cryogenic fatigue resistance?

- The exceptional performance of special steel lies in its ability to resist cryogenic fatigue. Cryogenic fatigue occurs when a material's structural integrity deteriorates under repeated loading and unloading at extremely low temperatures. Special steel, also known as high-performance or high-strength steel, surpasses conventional steels in its resistance to cryogenic fatigue. The enhanced cryogenic fatigue resistance of special steel can be attributed to its distinctive composition and microstructure. Special steels are typically alloyed with elements like nickel, chromium, and molybdenum, which enhance their mechanical properties, including strength and toughness, even at low temperatures. These alloying elements enable the steel to maintain its integrity and resist the initiation and propagation of cracks, which are common failure mechanisms in cryogenic environments. Moreover, the manufacturing process of special steel meticulously controls its microstructure to ensure optimal performance in cryogenic conditions. The fine-grained structure of special steel diminishes the susceptibility to fatigue cracks by promoting a more evenly distributed stress and strain throughout the material. This prevents the formation of localized stress concentrations, which can lead to crack initiation and subsequent failure. Apart from its composition and microstructure, special steel undergoes rigorous testing and quality control measures to guarantee its cryogenic fatigue resistance. Various industry standards and specifications, such as the ASTM E466 test method, exist to evaluate the performance of special steel in cryogenic conditions. These tests simulate the cyclic loading and unloading that the material may encounter in cryogenic environments and provide valuable data on its fatigue life and durability. In conclusion, special steel exhibits exceptional resistance to cryogenic fatigue due to its unique composition, controlled microstructure, and meticulous testing. Its ability to endure repeated loading and unloading at extremely low temperatures makes it the preferred choice for applications in industries like aerospace, energy, and cryogenic storage.

- Q:How does special steel perform in abrasive wear applications?

- Special steel is renowned for its outstanding performance in applications where abrasive wear is present. Its design specifically caters to endure the harsh conditions and high levels of abrasion that occur in diverse industrial processes. A notable characteristic of special steel is its remarkable hardness. It can effectively withstand the abrasive forces exerted by different materials, such as rocks, sand, or minerals, without experiencing significant wear or deterioration. Achieving this hardness involves a combination of alloying elements and heat treatment processes, which enhance the steel's ability to maintain its structural integrity even under extreme wear conditions. Furthermore, special steel often possesses a high level of toughness, allowing it to absorb impact and resist fracture or chipping. This property is particularly crucial in applications involving abrasive wear, where materials frequently collide and generate high levels of stress. The toughness of special steel enables it to withstand these impacts and sustain its performance over an extended period. Moreover, special steel exhibits excellent corrosion resistance, which is vital in abrasive wear applications that involve exposure to moisture, chemicals, or other corrosive agents. This resistance guarantees that the steel does not deteriorate or lose its effectiveness due to chemical reactions or oxidation, extending its lifespan and reducing the need for maintenance. To summarize, special steel excels in abrasive wear applications due to its hardness, toughness, and corrosion resistance. These properties enable it to endure the challenging conditions and high levels of abrasion encountered in various industrial processes, ensuring long-lasting performance and minimizing downtime.

- Q:How does special steel perform in magnetic applications?

- Special steel performs well in magnetic applications due to its high magnetic permeability and low electrical conductivity. This allows it to efficiently conduct and concentrate magnetic fields, making it ideal for various magnetic devices and applications such as transformers, motors, generators, and magnetic sensors. Additionally, special steel can exhibit excellent magnetic properties such as high saturation magnetization and low coercivity, making it capable of generating strong magnetic fields and maintaining magnetization even in challenging conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deformed Bars Grade JIS G3112-2004 SD345

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords